In a north London hospital, scientists are growing noses, ears and blood vessels in the laboratory in a bold attempt to make body parts using stem cells. It is among several labs around the world, including in the U.S., that are working on the futuristic idea of growing custom-made organs in the lab.

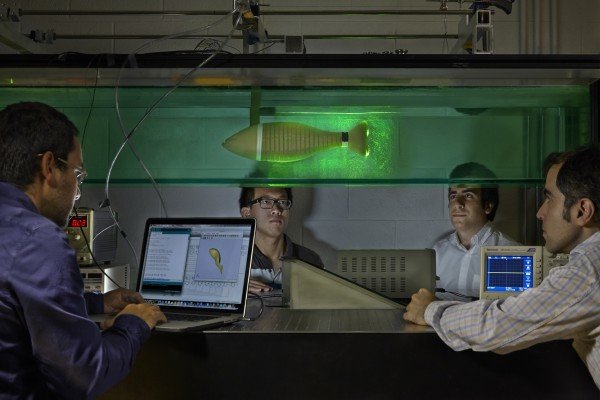

Dr Michelle Griffin, a plastic research fellow, poses for photographs with a synthetic polymer ear in London, where scientists are growing noses, ears and blood vessels in the laboratory in a bold attempt to make body parts using stem cells. Photo Credits: Matt Dunham, AP

While only a handful of patients have received the British lab-made organs so far— including tear ducts, blood vessels and windpipes—researchers hope they will soon be able to transplant more types of body parts into patients, including what would be the world’s first nose made partly from stem cells.

“It’s like making a cake,” said Alexander Seifalian at University College London, the scientist leading the effort. “We just use a different kind of oven.”

During a recent visit to his lab, Seifalian showed off a sophisticated machine used to make molds from a polymer material for various organs.

Last year, he and his team made a nose for a British man who lost his to cancer. Scientists added a salt and sugar solution to the mold of the nose to mimic the somewhat sponge-like texture of the real thing. Stem cells were taken from the patient’s fat and grown in the lab for two weeks before being used to cover the nose scaffold. Later, the nose was implanted into the man’s forearm so that skin would grow to cover it.

Seifalian said he and his team are waiting for approval from regulatory authorities to transfer the nose onto the patient’s face but couldn’t say when that might happen

The potential applications of lab-made organs appear so promising even the city of London is getting involved: Seifalian’s work is being showcased on Tuesday as Mayor Boris Johnson announces a new initiative to attract investment to Britain’s health and science sectors so spin-off companies can spur commercial development of the pioneering research.

The polymer material Seifalian uses for his organ scaffolds has been patented and he’s also applied for patents for their blood vessels, tear ducts and windpipe. He and his team are creating other organs including coronary arteries and ears. Later this year, a trial is scheduled to start in India and London to test lab-made ears for people born without them.

“Ears are harder to make than noses because you have to get all the contours right and the skin is pulled tight so you see its entire structure,” said Dr. Michelle Griffin, a plastic surgeon who has made dozens of noses and ears in Seifalian’s lab.

“At the moment, children who need new ears have to go through a really invasive procedure involving taking cartilage from their ribs,” Griffin said, adding that taking fat cells from patients’ abdomens to add to a lab-made ear scaffold would be far easier than the multiple procedures often necessary to carve an ear from their ribs. Griffin added they plan to eventually create an entirely synthetic face but must first prove their polymer scaffolds won’t accidentally burst out of the skin.

“Scientists have to get things like noses and ears right before we can move onto something like a kidney, lungs or a liver, which is much more complicated,” said Eileen Gentleman, a stem cell expert at King’s College London, who is not involved in Seifalian’s research.

“Where Seifalian has led is in showing us maybe we don’t need to have the absolutely perfect tissue for a (lab-made) organ to work,” she said. “What he has created is the correct structure and the fact that it’s good enough for his patients to have a functional (windpipe), tear duct, etc. is pretty amazing.”

Some scientists predicted certain lab-made organs will soon cease to be experimental.

“I’m convinced engineered organs are going to be on the market soon,” said Suchitra Sumitran-Holgersson, a professor of transplantation biology at the University of Gothenburg in Sweden. She has transferred lab-made blood vessels into a handful of patients and plans to offer them more widely by 2016, pending regulatory approval. Still, she acknowledged doctors will have to watch closely for any long-term side effects, including the possibility of a higher cancer risk.

Seifalian estimated about 10 million pounds ($16 million) has gone into his research since 2005 but said he hoped lab-made organs would one day be available for a few hundred dollars.

“If people are not that fussy, we could manufacture different sizes of noses so the surgeon could choose a size and tailor it for patients before implanting it,” he said. “People think your nose is very individual and personal but this is something that we could mass produce like in a factory one day.”

Story Source:

The above story is based on materials provided by AP, Maria Cheng.