Credit: POSTECH

Professor Byoungwoo Kang develops a high-density cathode material through controlling local structures of the Li-rich layered materials.

Researchers in Korea have developed a high-capacity cathode material that can be stably charged and discharged for hundreds of cycles without using the expensive cobalt (Co) metal. The day is fast approaching when electric vehicles can drive long distances with Li- ion batteries.

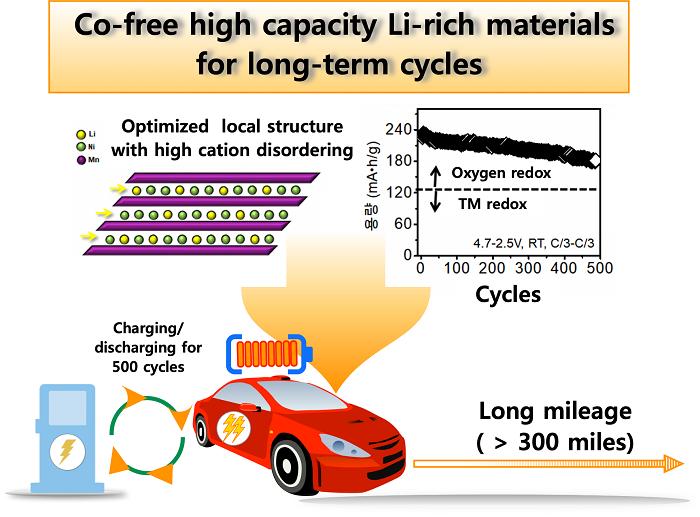

Professor Byoungwoo Kang and Dr. Junghwa Lee of POSTECH’s Department of Materials Science and Engineering have successfully developed a high energy-density cathode material that can stably maintain charge and discharge for over 500 cycles without the expensive and toxic Co metal. The research team achieved this by controlling the local structure via developing the simple synthesis process for the Li-rich layered material that is attracting attention as the next-generation high-capacity cathode material. These research findings were published in ACS Energy Letters, a journal in the energy field of the American Chemistry Association.

The mileage and the charge-discharge cycle of an electric vehicle depend on the unique properties of the electrode material in the rechargeable Li-ion battery. Electricity is generated when lithium ions flow back and forth between the cathode and anode. In the case of Li-rich layered material, the number of cycles decreases sharply when large amount of lithium is extracted and inserted. In particular, when a large amount of lithium is extracted and an oxygen reaction occurs in a highly charged state, a structural collapse occurs rendering it impossible to maintain the charge-discharge properties or the high-energy density for long-term cycles. This deterioration of the cycle property has hampered commercialization.

The research team had previously revealed that the homogeneous distribution of atoms between the transition metal layer and the lithium layer of the Li-rich layered material can be an important factor in the activation of electrochemical reaction and cycle property in Li-rich layered materials. The team then conducted a subsequent research to control the synthesis conditions for increasing the degree of the atoms’ distribution in the structure. Using the previously published solid-state reaction, the team developed a new, simple and efficient process that can produce a cathode material that has an optimized atomic distribution.

As a result, it was confirmed that the synthesized Li-rich layered material has an optimized local structure in terms of electrochemical activity and cycle property, enabling a large amount of lithium to be used reversibly. It was also confirmed that the oxygen redox reaction was also stably and reversibly driven for several hundred cycles.

Under these optimized conditions, the Co-free Li-rich layered material synthesized displayed 180% higher reversible energy at 1,100Wh/kg than the conventionally commercialized high nickel layered material (ex. LiNi0.8Mn0.1Co0.1O2) with energy density of 600Wh/kg. In particular, even if a large amount of lithium is removed, a stable structure was maintained, enabling about 95% capacity for 100 cycles. In addition, by maintaining 83% for 500 cycles, a breakthrough performance that can maintain stable high energy for hundreds of cycles is anticipated.

“The significance of these research findings is that the cycle property, which is one of the important issues in the next-generation high-capacity Li-rich layered materials, have been dramatically improved through relatively simple process changes,” explained Professor Byoungwoo Kang of POSTECH. “This is noteworthy in that we have moved a step closer to commercializing the next generation Li-rich layered materials.”

###

This research was conducted with the support from the Mid-career Researcher Program and the Radiation Technology Development Project of the National Research Foundation of Korea.

Media Contact

Jinyoung Huh

[email protected]

Original Source

http://postech.

Related Journal Article

http://dx.