Functional silica beads for biomedical imaging, drug delivery and other important applications could be made using an easy new flow synthesis method.

Credit: Yang Hui

Researchers in Australia and China have proposed an innovative and cost-effective new method for creating silica beads, which have a number of key uses, ranging from nanomedicine and bioimaging to the production of paper and polished concrete.

The synthesis of silica particles for experimental and industrial uses began in the 1960s, and usually takes place in large batches, where controlled doping to induce functionality is difficult.

Control of the synthesis parameters can be achieved through costly and time-consuming small-scale microfluidic reactors that require photolithography, etching, bonding and injection moulding, which are prone to clogging.

Now, a surprisingly simple new approach has been demonstrated, and could be adopted for various applications at a low cost and with a high degree of reliability.

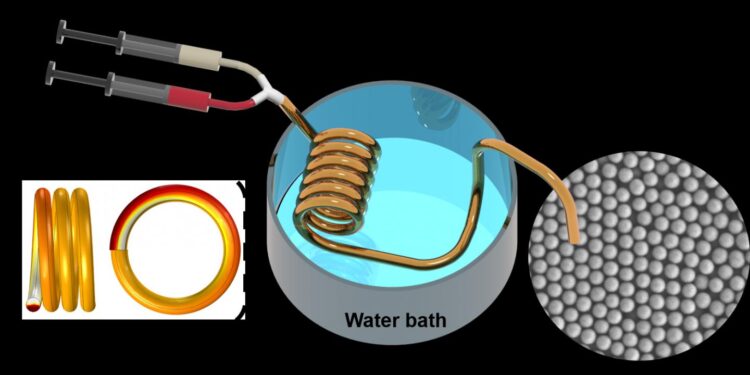

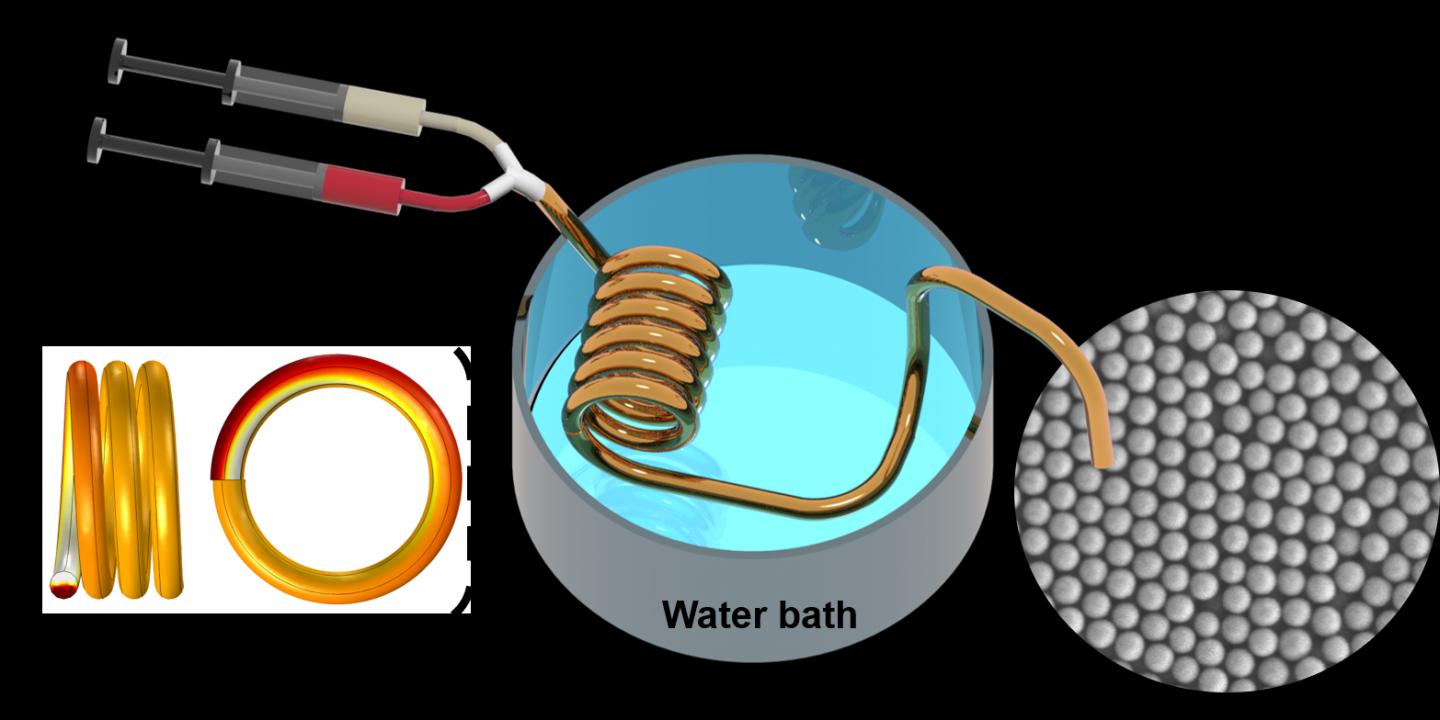

Researchers at the ARC Centre of Excellence in Exciton Science, based at The University of Melbourne, and working with colleagues at South China Normal University, constructed a flow synthesis device using a polytetrafluoroethylene (PTFE) or ‘Teflon’ pipe wound around a rod and connected to two syringes.

The key to the success of this approach is a spiral channel which promotes vortex flow characteristics, and this type of fluid flow encourages extremely efficient mixing of the precursor fluids.

“When this happens you now have this very cheap and quite efficient chemical reactor,” corresponding author Dr Eser Akinoglu said.

“Once you have the fluids in a tube that is spiralled, then due to these vortexes, they mix very quickly and … the overall reaction is more homogeneous, the product is homogeneous, and the silica particles have a uniform size and shape.”

While this new mechanism is unlikely to replace industrial-scale batch manufacturing for the creation of pure silica particles, it could well rival the microfluidic approach used in synthesising silica nanoparticles for specialised, niche applications, such as silica particles ‘doped’ with colourful dyes or encapsulating quantum dots for fluorescence.

“From a material costs perspective, it’s very reasonable,” Dr Akinoglu said.

“For the future, this flow synthesis method is ideal for the introduction of new components into the reaction … you could put something else into this flow to mix together with the whole process and it will then be encapsulated in these silica particles.”

###

Media Contact

Iain Strachan

[email protected]

Related Journal Article

http://dx.