Fresh banana, a waft of flowers, blueberry: the scents in Shota Atsumi’s laboratory in the UC Davis Department of Chemistry are a little sweeter than most. That’s because Atsumi and his team are engineering bacteria to make esters — molecules widely used as scents and flavorings, and also as basic feedstock for chemical processes from paints to fuels.

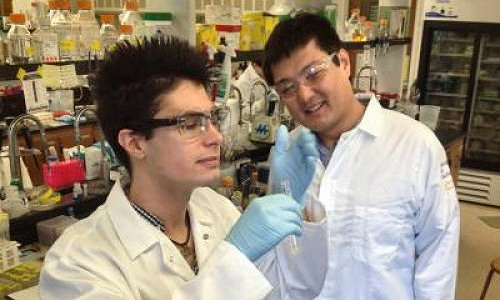

UC Davis graduate student Gabriel Rodriguez, left, and Shota Atsumi, assistant professor of chemistry sample a culture of E. coli engineered to produce a sweet-smelling ester. Esters are key to the $20 billion-a-year scents and flavorings industry, but almost all are currently derived from oil and gas. New technology invented at UC Davis allows specific esters to be made by microbes – Credit: Andy Fell/UC Davis

Their latest work is published March 9 in the journal Nature Chemical Biology.

Nearly all industrial chemicals, from artificial flavorings to paint, are derived from oil or gas, Atsumi said.

“Our motivation is to make chemicals from renewable sources instead,” Atsumi said. Scents and flavorings make up a $20 billion industry worldwide, he said.

Esters are molecules in which two chains of carbon atoms are linked through an oxygen atom. They are made chemically by reacting an alcohol with an organic acid. But the thermodynamics of this reaction mean that it tends to run the other way — it’s easier to break up an ester than to make it.

Living cells can also make esters. For example, yeasts produce small amounts of esters that give flavors to wine and beer, without requiring high temperatures or special conditions.

“The reaction is chemically difficult but biologically easy,” Atsumi said. “Nature gives you a great system to work with.”

Nature uses a class of enzymes called alcohol O-acetyltransferases to make esters from acyl-Coenzyme A (acyl-CoA) molecules. These consist of a carbon chain of variable length, attached to a coenzyme A subunit. Loss of coenzyme A during the reaction provides energy to drive the process.

Changing the acyl- part of acyl-CoA that goes into the reaction changes the type of ester that is produced.

Atsumi, graduate student Gabriel Rodriquez and postdoctoral researcher Yohei Tashiro took genes for biochemical pathways from yeast and introduced them into E. coli bacteria, a reliable test system for genetic engineering. By tweaking the Acyl-CoA pathway, they could manipulate one half of the ester: by adjusting the pathway that produces alcohols in the cell, and by shutting down other potential pathways, they could adjust the other half. Therefore, they were able to pick the final ester made by the bacteria.

The technique, which has been patented, opens up possibilities for producing many different esters in biological systems, Atsumi said. The source material for the bacteria is based on sugars, which can come from renewable biomass. Ultimately, Atsumi hopes to engineer these chemical pathways into cyanobacteria (blue-green algae), single-celled organisms that can draw energy directly from sunlight and carbon from the atmosphere.

Story Source:

The above story is based on materials provided by University of California – Davis, Andy Fell.