Credit: American Chemical Society

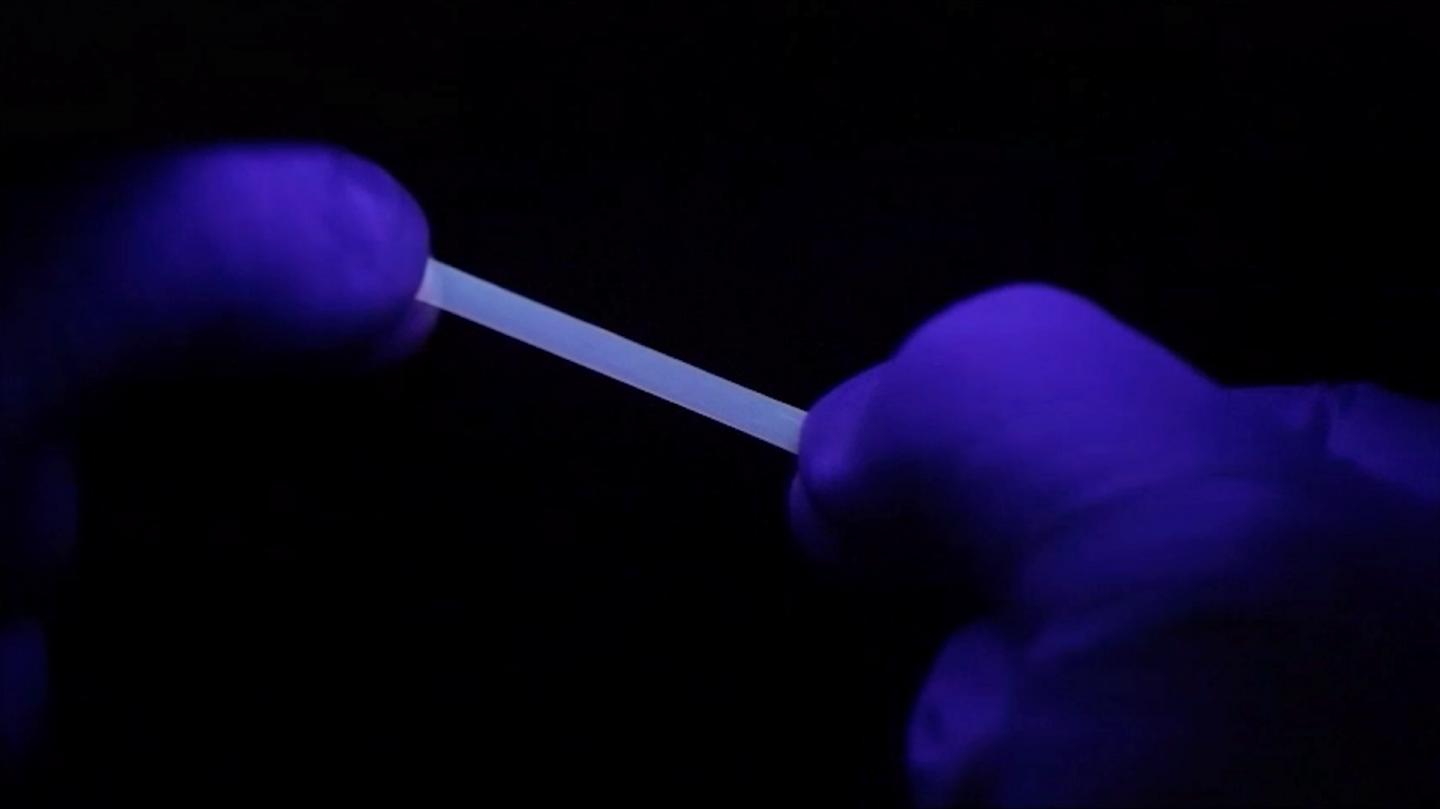

Polymers that change their appearance in response to mechanical forces can warn of damage developing in a material before the stress causes structural failure. Researchers now report in ACS Central Science that they’ve developed a first-of-its-kind elastic polymer blend that displays white fluorescence when deformed and then goes dark after relaxing back to its original shape.

A general approach to create such stress-sensing polymers is to integrate sensor molecules that change their optical properties when activated by mechanical force. In most previous types of these polymers, however, activation is irreversible because it breaks covalent bonds in the sensors. These bonds can also be unintentionally broken by other stimuli, such as heat or light, so an optical change doesn’t always prove the material has been mechanically damaged. Yoshimitsu Sagara, Christoph Weder and colleagues wanted to overcome these disadvantages. To do this, they built upon their previous work, published last year, in which they reported a polyurethane containing stress-sensing rotaxane consisting of ring-shaped fluorescent molecules threaded on dumbbell-shaped molecules featuring quencher groups at their center. In the relaxed polymer, the quenchers were near the fluorescent rings and prevented them from glowing under ultraviolet light. Stretching the polymer moved the quenchers and fluorescent rings apart, so the material glowed green. The process was fully reversible and couldn’t be triggered by heat or light.

In the current study, the researchers developed three new polyurethanes that glowed blue, green or orange when stretched, demonstrating that the color can be tailored simply by using different cyclic fluorescent rings in the rotaxanes. The materials emitted light of greater or lesser intensity, depending on how much they were stretched. By combining the three polymers, the researchers say they created the first white-light-emitting polymer that can instantly be switched on and off mechanically. Applications include study of the physical forces in cells and tissues, as well as visualizing damage in polymeric materials.

###

A video of the material being stretched can be found on the ACS YouTube Headline Science channel (or click here to directly access the video).

The authors acknowledge funding from Japan Science and Technology Agency, PRESTO (JPMJPR17P6) and the Swiss National Center of Competence in Research Bio-Inspired Materials.

The paper’s abstract will be available on April 24 at 8 a.m. Eastern time here:

http://pubs.

The American Chemical Society, the world’s largest scientific society, is a not-for-profit organization chartered by the U.S. Congress. ACS is a global leader in providing access to chemistry-related information and research through its multiple databases, peer-reviewed journals and scientific conferences. ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies. Its main offices are in Washington, D.C., and Columbus, Ohio.

To automatically receive news releases from the American Chemical Society, contact [email protected].

Follow us: Twitter | Facebook

Media Contact

Katie Cottingham

[email protected]