One of the key features of this technology is that the wire is used instead of powder for metal parts 3D printing.

Credit: Peter the Great St.Petersburg Polytechnic University

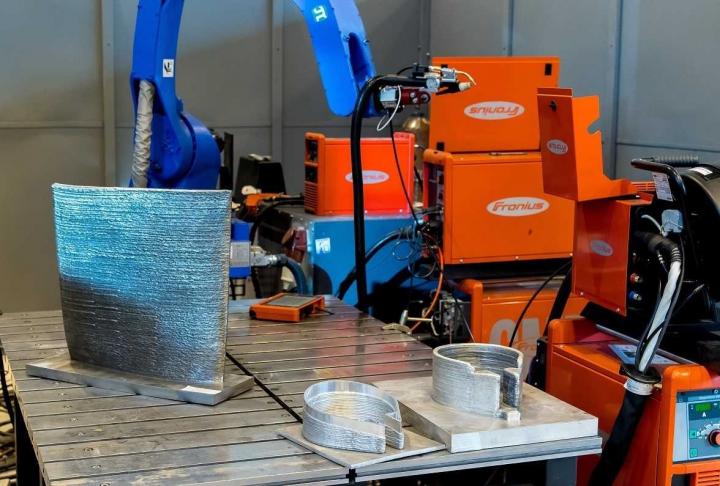

Engineers of Peter the Great St.Petersburg Polytechnic University (SPbPU) are developing the wire and arc additive manufacturing technology (WAAM). One of the key features of this technology is that the wire is used instead of powder for metal parts for 3D printing. This technology can significantly reduce the cost of additive manufacturing. This technology can also compete with subtractive manufacturing methods such as milling in cost efficiency.

The research is being carried out in the framework of the national project “Science”.

For this technology, an industrial robot and a welding power source are required for printing. Printing can also be followed by milling, whether it is necessary to obtain surfaces of low roughness and high precision. Both printing and milling strategies are programmed via CAM using a CAD model. As a result – manufactured by WAAM part has a digital twin.

The researchers of the Laboratory of Lightweight Materials and Structures SPbPU developed special arc and voltage waveforms for the metal deposition process to increase wire feed rate twice compare to the usual WAAM techniques. Thus, the printing productivity was increased.

Russian industrial companies are interested in this technology. Upon request of an industrial partner, the scientific group from the St.Petersburg Polytechnic University printed the fan blade with a height of half a meter and a weight of almost 60 kg. Such blades are used in large factory ventilation fans.

“We save the time for the industry: we have printed the fan blade using the wire within one day, it will take more than a week to print it using the powder. We save the material for the industry: this blade is hollow inside, and such part can’t be manufactured by casting or milling technologies alone. We give the industry the opportunity to choose any design: the developed technology doesn’t impose the technological limitations on the shape of the final product,” said Oleg Panchenko, head of the Laboratory of Lightweight Materials and Structures SPbPU.

It should be noted that the metal powder, the material which is mainly used for the metal parts in additive manufacturing, is expensive and requires a large infrastructure of additional equipment for its maintenance. For instance, the cost of the aluminum wire is about 15$ per kilogram, while the price of aluminum powder is 10 or sometimes even 20 times higher.

Moreover, in the case of milling the material is consumed uneconomically. In subtractive manufacturing the weight of the raw workpiece before milling is 8 -30 weights of the final product, thus, 87.5% – 97% of the original material is wasted.

WAAM has its advantages even over the casting technology, for which the expensive mold is created and used repeatedly, which is profitable for mass production. The technology developed by the researchers of SPbPU is also suitable for serial manufacturing. In addition, the additive process may be interrupted to remove the discovered defect, which is impossible in case of casting, where the entire workpiece is discarded if defected.

###

Media Contact

Raisa Bestugina

[email protected]

7-812-591-6675