New method turns foam into higher value rubber and hard plastics

Credit: Northwestern University

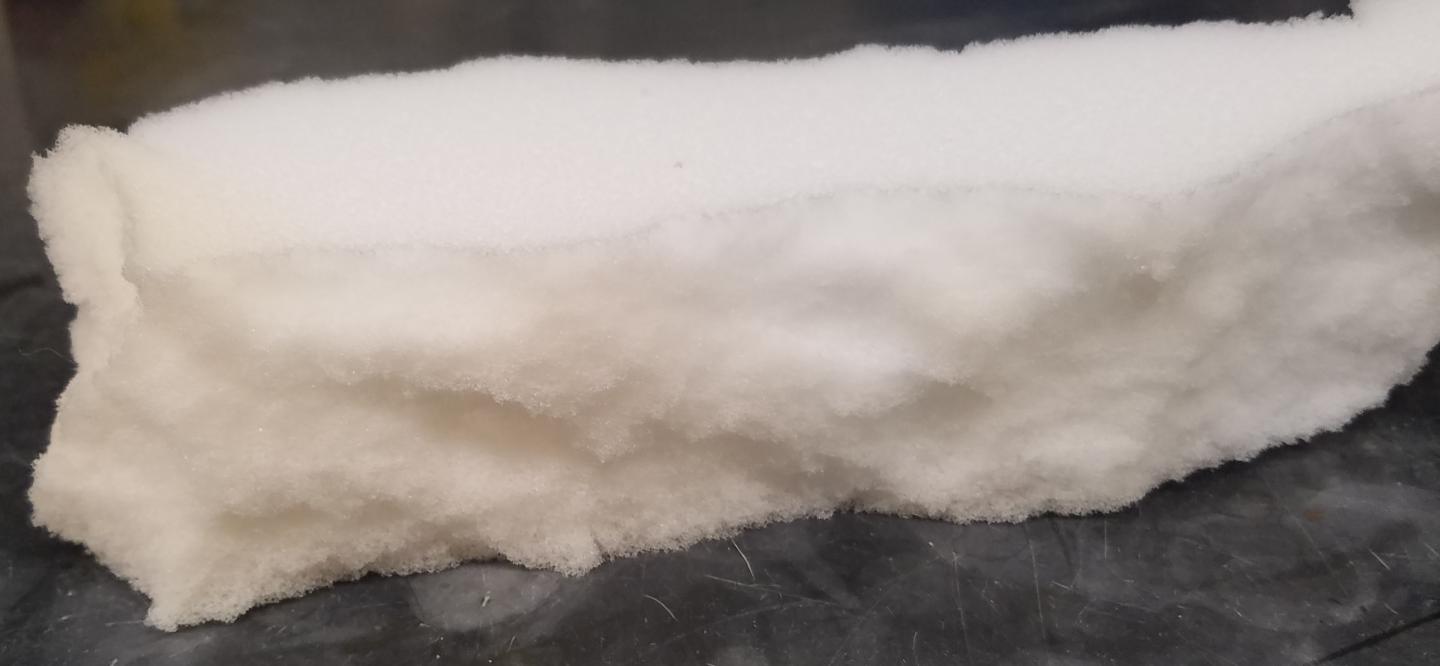

EVANSTON, Ill. — Researchers have developed a new method for upcycling polyurethane foams, the spongy material found in mattresses, insulation, furniture cushions and shoes.

This process, developed by researchers at Northwestern University and the University of Minnesota, first involves mixing postconsumer polyurethane foam waste with a catalyst solution that allows the foam to become malleable. Next, the method uses a “twin-screw” extrusion process that both removes air from the foam to create a new material in the shape of a hard, durable plastic or soft, flexible film as well as remolds the material.

This allows foam waste to be processed into higher quality rubbers and hard plastics for use in shoe cushioning, watch wristbands, hard durable wheels (for shopping carts and skateboards) and in automotive applications, such as bumpers.

“Polyurethane foam waste has historically been landfilled and burned or downcycled for use in carpeting,” said Northwestern’s William Dichtel, who co-led the research. “Our latest work effectively removes air from polyurethane foams and remolds them into any shape. This could pave the way for industry to begin recycling polyurethane foam waste for many relevant applications.”

The research will be published April 29 in the journal ACS Central Science.

Dichtel is the Robert L. Letsinger Professor of Chemistry in Northwestern’s Weinberg College of Arts and Sciences. He co-led the research with Christopher Ellison, an associate professor of chemical engineering and materials science at the University of Minnesota.

Often made from toxic building blocks, polyurethane foam is a stubborn material that frequently ends up at the bottom of landfills. While other types of plastics can be melted down and recycled, polyurethane foam’s chemical bonds are so strong that it does not melt — even in extreme heat. At best, people can shred it into synthetic fibers, which can then be downcycled into carpet and brushes.

Other upcycling efforts have compressed the foam to remove its air, but this resulted in cracked or unevenly blended materials. Dichtel and Ellison’s approach uses two intermeshing, co-rotating screws to simultaneously mix and remold the foam. This improved mixing and air removal.

###

The study, “Reprocessing postconsumer polyurethane foam using carbamate exchange catalysis and twin-screw extrusion,” was supported by the National Science Foundation and the Keck Foundation.

More news at Northwestern Now

Find experts on our Faculty Experts Hub

Follow @NUSources for expert perspectives

Media Contact

Amanda Morris

[email protected]