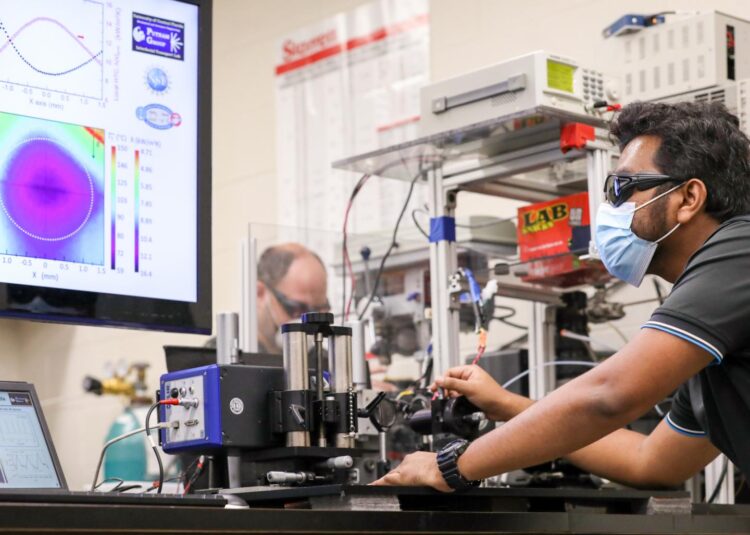

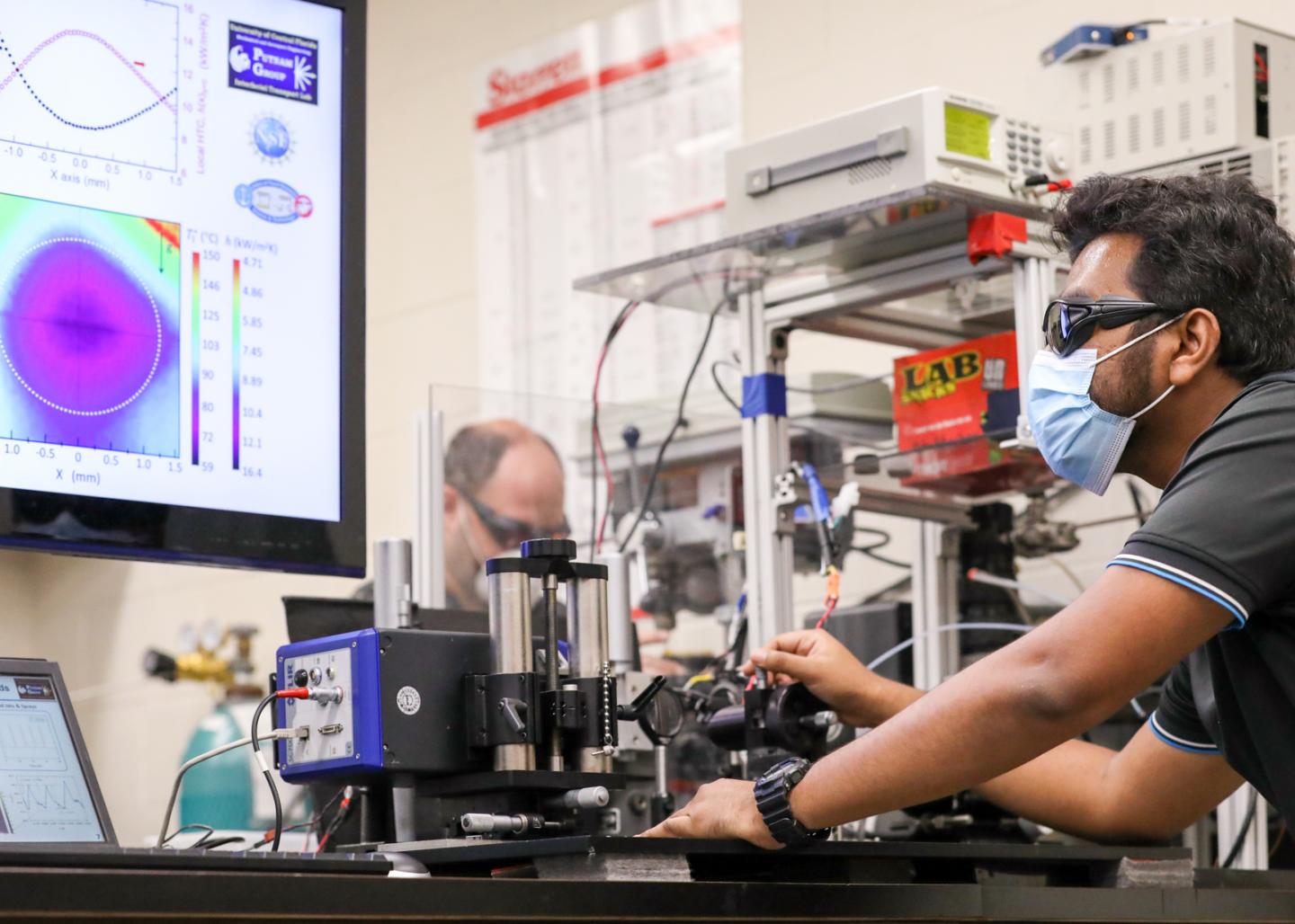

The UCF researchers are developing a way for large machines to “breathe” in and out cooling blasts of water to keep their systems from overheating.

Credit: Karen Norum, University of Central Florida Office of Research

ORLANDO, Oct. 13, 2020 – In the era of electric cars, machine learning and ultra-efficient vehicles for space travel, computers and hardware are operating faster and more efficiently. But this increase in power comes with a trade-off: They get superhot.

To counter this, University of Central Florida researchers are developing a way for large machines to “breathe” in and out cooling blasts of water to keep their systems from overheating.

The findings are detailed in a recent study in the journal Physical Review Fluids.

The process is much like how humans and some animals breath in air to cool their bodies down, except in this case, the machines would be breathing in cool blasts of water, says Khan Rabbi, a doctoral candidate in UCF’s Department of Mechanical and Aerospace Engineering and lead author of the study.

“Our technique used a pulsed water-jet to cool a hot titanium surface,” Rabbi says. “The more water we pumped out of the spray jet nozzles, the greater the amount of heat that transferred between the solid titanium surface and the water droplets, thus cooling the titanium. Fundamentally, an idea of optimum jet-pulsation needs to be generated to ensure maximum heat transfer performance.”

“It is essentially like exhaling the heat from the surface,” he says.

The water is emitted from small water-jet nozzles, about 10 times the thickness of a human hair, that douse a hot surface of a large electronic system and the water is collected in a storage chamber, where it can be pumped out and circulated again to repeat the cooling process. The storage chamber in their study held about 10 ounces of water.

Using high-speed, infrared thermal imaging, the researchers were able to find the optimum amount of water for maximum cooling performance.

Rabbi says everyday applications for the system could include cooling large electronics, space vehicles, batteries in electric vehicles and gas turbines.

Shawn Putnam, an associate professor in UCF’s Department of Mechanical and Aerospace Engineering and study co-author, says that this research is part of an effort to explore different techniques to efficiently cool hot devices and surfaces.

“Most likely, the most versatile and efficient cooling technology will take advantage of several different cooling mechanisms, where pulsed jet cooling is expected to be one of these key contributors,” Putnam says.

The researcher says there are multiple ways to cool hot hardware, but water-jet cooling is a preferred method because it can be adjusted to different directions, has good heat-transfer ability, and uses minimum amounts of water or liquid coolant.

However, it has its drawbacks, namely either over or underwatering that results in floods or dry hotspots.

The UCF method overcomes this problem by offering a system that is tunable to hardware needs so that the only water applied is the amount needed and in the right spot.

The technology is needed since once device temperatures surpass a threshold value, for example, 194 degrees Fahrenheit, the device’s performance decreases, Rabbi says.

“For this reason, we need better cooling technologies in place to keep the device temperature well within the maximum temperature for optimum operation,” he says. “We believe this study will provide engineers, scientists and researchers a unique understanding to develop future generation liquid cooling systems.”

###

Jake Carter, a former undergraduate in UCF’s Department of Mechanical and Aerospace Engineering and now a graduate student at the University of California, Berkeley, also co-authored the study.

Rabbi received his bachelor’s in mechanical engineering from Bangladesh University of Engineering and Technology and joined UCF’s mechanical engineering doctoral program in 2017. Since starting UCF, he has also completed successful internships with Nokia Bell Labs and semiconductor equipment supplier ASML.

Putnam received his doctorate in materials science and engineering from the University of Illinois Urbana-Champaign and his bachelor of physics and bachelor of science in applied mathematics degrees from the University of Minnesota Duluth. He joined UCF’s Department of Mechanical and Aerospace Engineering, part of UCF’s College of Engineering and Computer Science, in 2012.

The research was funded by the U.S. Office of Naval Research and the National Science Foundation.

CONTACT: Robert H. Wells, Office of Research, [email protected]

Media Contact

Robert H Wells

[email protected]

Related Journal Article

http://dx.