Principal researcher Soon Moon Jeong at DGIST developed in-plane electro-luminescent(EL) technology that inserts electrodes into a luminous layer

Credit: DGIST

Dr. Soon Moon Jeong’s research team in the Division of Energy Technology at DGIST has developed a new structure of luminescence technology. This will enable the production of light-emitting elements that overcome the limitations of existing methods, expecting to greatly help improve the efficiency of light-emitting elements used in various ways such as billboards and banners.

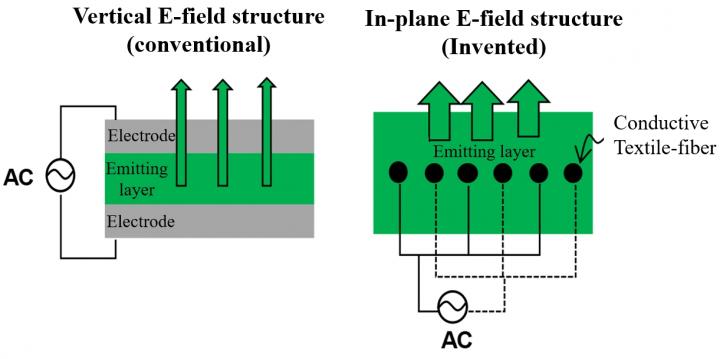

Light emitting devices need electrodes to transmit energy to the light emitting layer. The ‘flat electrode’ used here is an electrode consists of a coplanar structure surrounding the light emitting layer, which has limitation as the light emitted from the light emitting layer is blocked by the electrode. The decreasing flexibility of the electrodes was also an obstacle to manufacturing a flexible light emitting device that emits light constantly.

To overcome these limitations, Dr. Jeong’s team cross-inserted a new type of electrode made of fibers inside the light emitting layer unlike existing light emitting devices, through which they could develop a new light-emitting technology using an in-plane electric field generated in parallel to the light-emitting layer. The light-emitting device produced this way improved efficiency significantly by emitting light more flexibly and stably than the existing light-emitting devices.

Dr. Jeong’s research team applied a new luminescent film using zinc sulfide (ZnS) and polydimethylsiloxane (PDMS) to the luminescent layer while using the in-plane electric field. Through this, they made possible at the same time the mechanoluminescence (ML) which generates light by applying mechanical force and electroluminescence (EL) which generates light by operating the electric field. While it was not possible in the conventional light emitting devices, this new technology could maintain constant and efficient light intensity in various environments.

The light-emitting device developed this time provided important clues to overcome various limitations of the existing light-emitting device. First, the structure of light emitting device developed by Dr. Jeong’s team solved the problem of the existing light emitting device in which electrodes are inserted into the light emitting layer and block light. By doing so, the research team also solved at once the disadvantage that thick electrodes needed to further increase the light intensity of light emitting device rather blocking the light of the light emitting layer between them.

Dr. Jeong in the Division of Energy Technology said “We want to change the paradigm of related industries in the future through the development of devices that emit light constantly, despite any changes of forms. This is definitely possible if we improve the light emitting device further, and it is expected to be used in various forms of light emitting textile and wearable devices.”

This research finding was published on the latest issue of Materials Today, a world-renowned international journal in materials engineering. This research was conducted with the support of DGIST and the mid-carrier researcher support project carried out by the Ministry of Science and ICT.

###

Media Contact

Kwanghoon Choi

[email protected]

Original Source

https:/

Related Journal Article

http://dx.