Credit: Fergus Cuthill

A £2.4 million engineering research facility will seek to speed the development of materials and structures for tidal energy, transport and other industries.

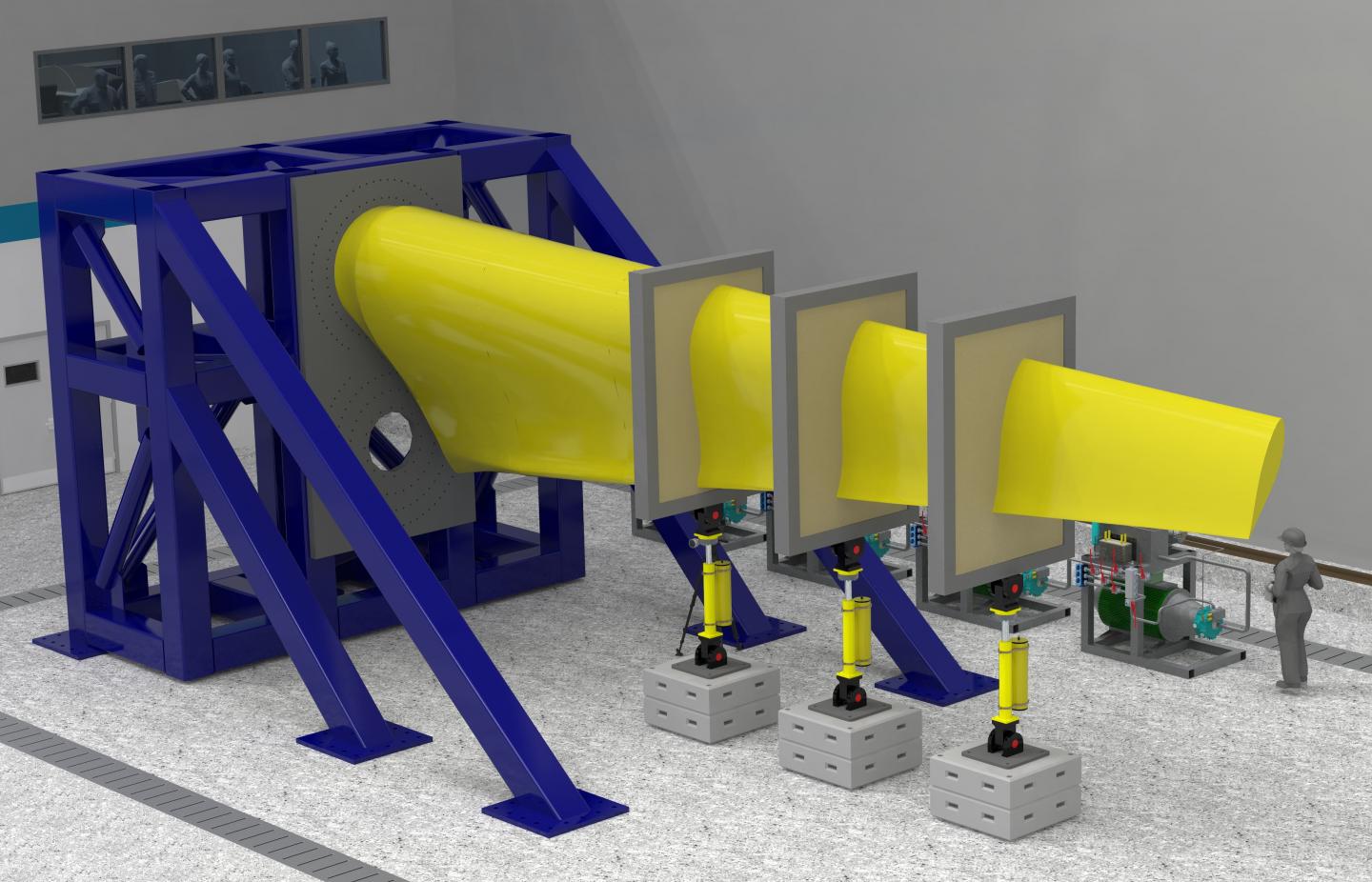

The FASTBLADE facility will test new materials within full scale structures such as tidal blades, plane components and bridge sections.

It will be built by the University of Edinburgh and commercial partner Babcock International at Rosyth in Fife, Scotland.

FASTBLADE will be the first facility in the world designed to carry out large-scale accelerated testing of tidal blades. Testing will use complex forces that simulate real environments, limiting the risks for product developers.

Engineering researchers will use an efficient hydraulic technology – developed by University spin-off company Artemis Intelligent Power – which enables structures to be tested significantly faster and using less energy compared with existing technologies. The system will recover energy between load cycles, reducing the cost of testing.

FASTBLADE’s first clients will include tidal stream developers. Tidal blades made of composite materials need to be designed to withstand high fatigue loads in harsh ocean conditions for up to 20 years.

Pioneering measurement systems will enable developers to learn from test datasets to understand damage accumulation and optimise blade structures through data-driven design.

FASTBLADE will help fulfil the University’s commitments as part of the Edinburgh and South East Scotland City Region Deal, which includes targets to help improve digital skills across the whole of the region.

The facility has received £1.4m from the Engineering and Physical Sciences Research Council and £1m from the University of Edinburgh. Babcock is the principal designer and host of the facility.

FASTBLADE is a key strand of a strategic partnership between Babcock and the University, developed with Edinburgh Innovations, the University’s commercialisation service.

Professor Conchúr Ó Brádaigh, Head of School of Engineering at the University of Edinburgh, and leader of the research activity, said: “This collaboration is an opportunity to develop a world-class engineering facility to accelerate and support the development of new efficient technologies, and will be a great benefit to the tidal energy sector.”

Neil Young, a Technology Director within Babcock, has been involved from the project’s concept. He said: “When the University approached us, they were looking for specialist facilities and engineering design expertise to help get the project from research application to reality. At Babcock’s facility in Rosyth, we had both these key requirements, which were not available anywhere else in a single location. We’ve worked in close partnership with the University to optimise the design of the reaction frame which the composite structure is mounted to. The design also included upgrading the foundation design in the building to accommodate the additional loads imposed by the fatigue testing.

“For us, this really is a great industrial partnership. Our engineers working alongside the University’s renowned academics has shown what the art of the possible is, in engineering and in working together. Whilst we are still at the early stages of development I know we are creating something that isn’t just a great opportunity for us, it will have real benefit for all the companies using the facility in years to come.”

###

Media Contact

Catriona Kelly

[email protected]

Original Source

https:/