Rice advances manufacture of complex shapeshifters for soft robots, biomedical implants

Credit: Verduzco Laboratory/Rice University

HOUSTON – (June 9, 2020) – Soft robots and biomedical implants that reconfigure themselves upon demand are closer to reality with a new way to print shapeshifting materials.

Rafael Verduzco and graduate student Morgan Barnes of Rice’s Brown School of Engineering developed a method to print objects that can be manipulated to take on alternate forms when exposed to changes in temperature, electric current or stress.

The researchers think of this as reactive 4D printing. Their work appears in the American Chemical Society journal ACS Applied Materials and Interfaces.

They first reported their ability to make morphing structures in a mold in 2018. But using the same chemistry for 3D printing limited structures to shapes that sat in the same plane. That meant no bumps or other complex curvatures could be programmed as the alternate shape.

Overcoming that limitation to decouple the printing process from shaping is a significant step toward more useful materials, Verduzco said.

“These materials, once fabricated, will change shape autonomously,” Verduzco said. “We needed a method to control and define this shape change. Our simple idea was to use multiple reactions in sequence to print the material and then dictate how it would change shape. Rather than trying to do this all in one step, our approach gives more flexibility in controlling the initial and final shapes and also allows us to print complex structures.”

The lab’s challenge was to create a liquid crystal polymer “ink” that incorporates mutually exclusive sets of chemical links between molecules. One establishes the original printed shape, and the other can be set by physically manipulating the printed-and-dried material. Curing the alternate form under ultraviolet light locks in those links.

Once the two programmed forms are set, the material can then morph back and forth when, for instance, it’s heated or cooled.

The researchers had to find a polymer mix that could be printed in a catalyst bath and still hold its original programmed shape.

“There were a lot of parameters we had to optimize — from the solvents and catalyst used, to degree of swelling, and ink formula — to allow the ink to solidify rapidly enough to print while not inhibiting the desired final shape actuation,” Barnes said.

One remaining limitation of the process is the ability to print unsupported structures, like columns. To do so would require a solution that gels just enough to support itself during printing, she said. Gaining that ability will allow researchers to print far more complex combinations of shapes.

“Future work will further optimize the printing formula and use scaffold-assisted printing techniques to create actuators that transition between two different complex shapes,” Barnes said. “This opens the door to printing soft robotics that could swim like a jellyfish, jump like a cricket or transport liquids like the heart.”

###

Co-authors of the paper are Rice graduate student Seyed Sajadi; Shaan Parekh, a student at John Foster Dulles High School in Sugar Land, Texas; Rice research scientist Muhammad Rahman; and Pulickel Ajayan, chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry. Verduzco is an associate professor of chemical and biomolecular engineering and of materials science and nanoengineering.

The Welch Foundation for Chemical Research and the Army Research Office Chemical Sciences Division supported the research.

Read the abstract at https:/

This news release can be found online at https:/

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Mighty morphing materials take complex shapes: http://news.

Verduzco Laboratory: http://verduzcolab.

Rice Department of Chemical and Biomolecular Engineering: https:/

George R. Brown School of Engineering: https:/

Video:

https:/

Credit: Verduzco Laboratory/Rice University

Images for download:

https:/

Rice engineer Rafael Verduzco and graduate student Morgan Barnes led the development of a method to 3D-print materials that morph from one shape to another through application of temperature, electric current or stress. (Credit: Jeff Fitlow/Rice University)

https:/

A graphic shows the process by which a Rice University lab uses 3D printing to make shapeshifting materials that may be useful to make soft robots or as biomedical implants. (Credit: Verduzco Laboratory/Rice University)

https:/

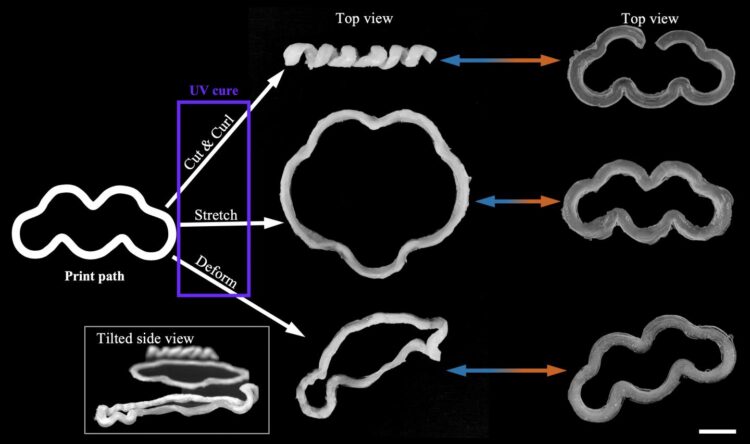

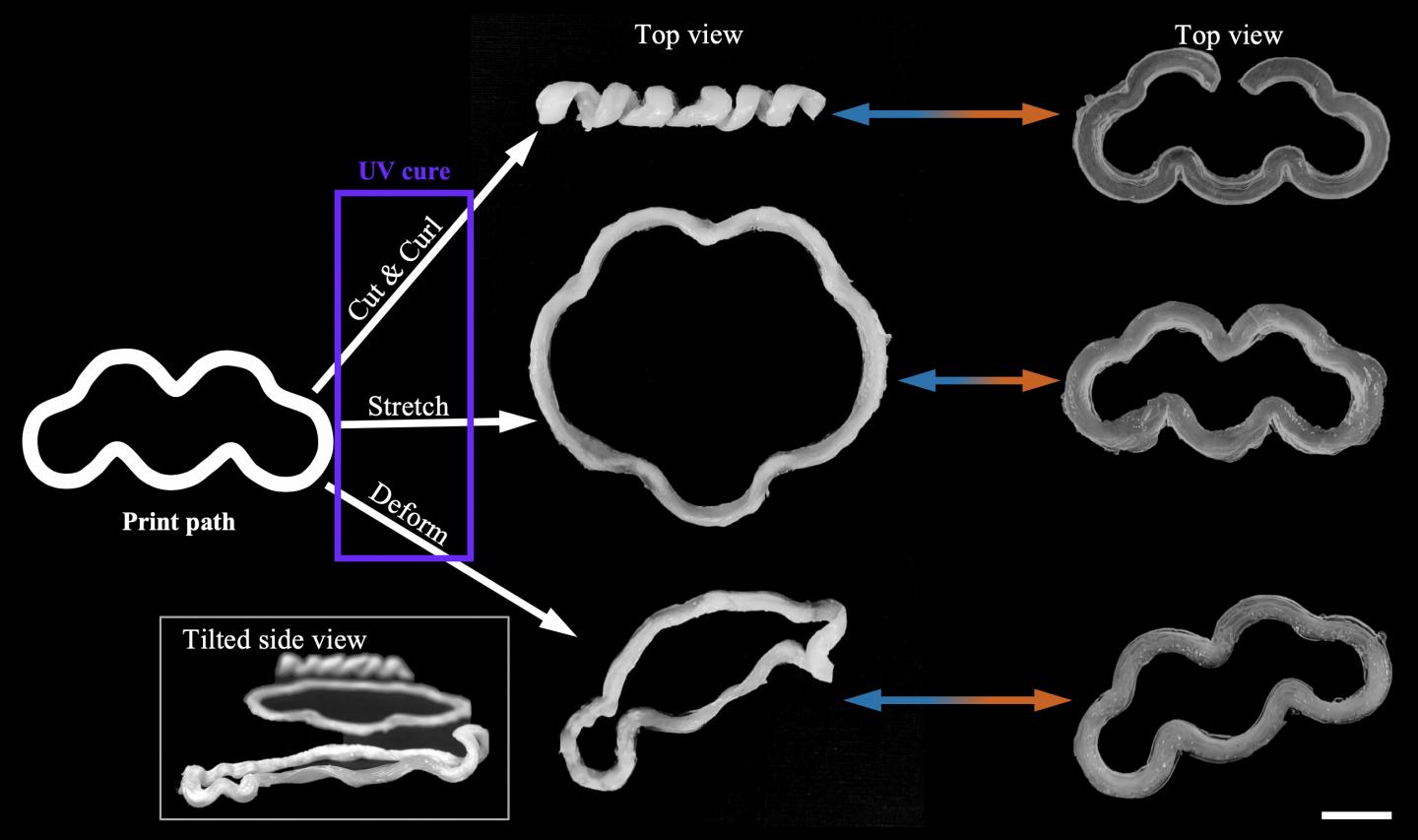

Shapeshifting materials produced at Rice University with a 3D printer morph from their original form to an alternate through changes in temperature, electric current or stress. This example shows how one printed configuration can be programmed to take various shapes. (Credit: Verduzco Laboratory/Rice University)

https:/

Shapeshifting materials 3D printed through a process developed at Rice University can be manipulated to take out-of-plane forms. The material incorporates two distinct sets of chemical links that can shift back and forth with temperature, current or strain inputs. (Credit: Verduzco Laboratory/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 4 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

Jeff Falk

713-348-6775

[email protected]

Mike Williams

713-348-6728

[email protected]

Media Contact

Jeff Falk

[email protected]

Original Source

https:/

Related Journal Article

http://dx.