A sticky solution could improve carbon capture materials

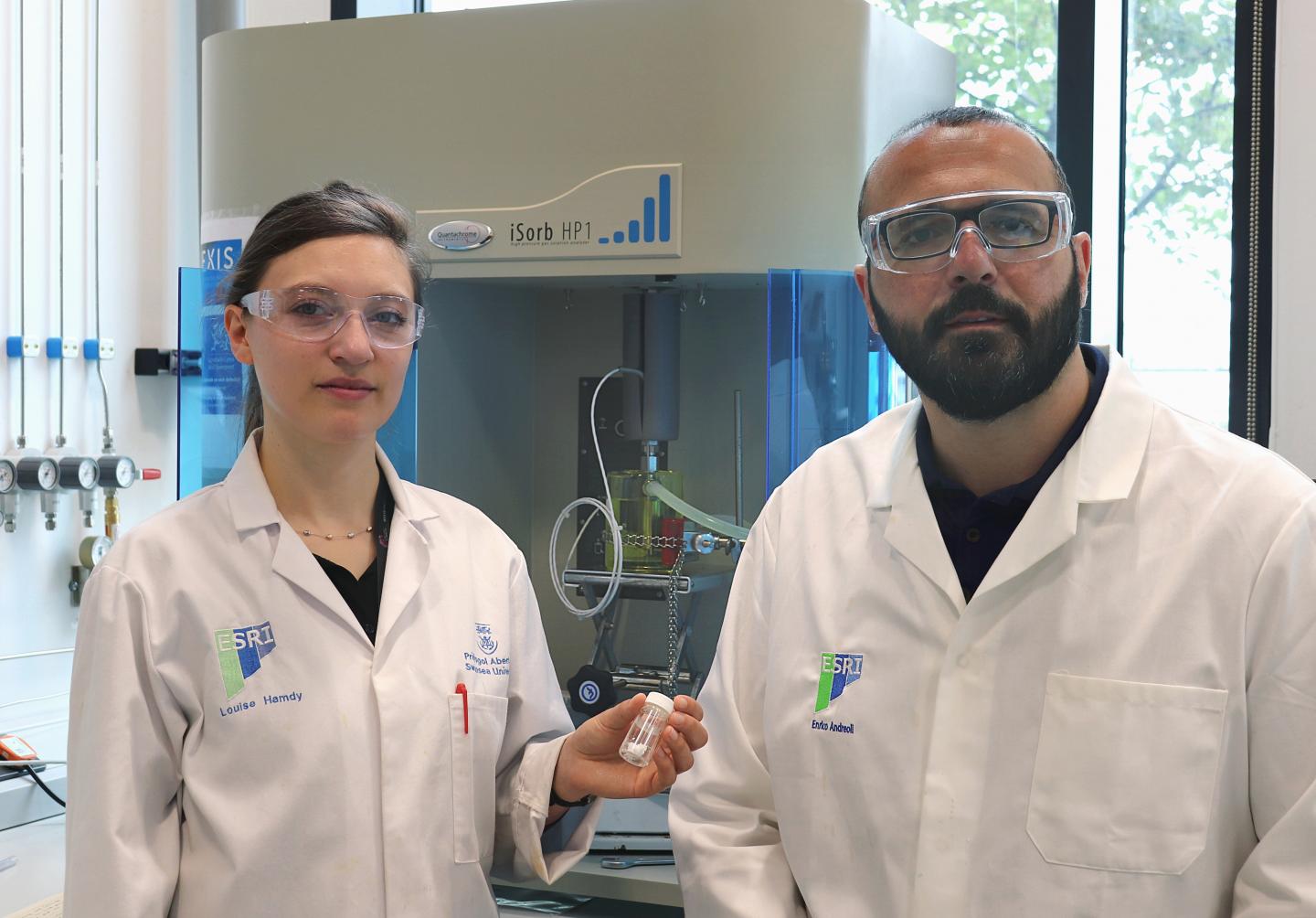

Credit: ESRI, Swansea University

Is glue the answer to climate change? Researchers at the Energy Safety Research Institute (ESRI) at Swansea University have proven that it could certainly help.

They have developed a new material capable of capturing the greenhouse gas carbon dioxide (CO2) with the key ingredient being a common epoxy resin you probably have at home.

Carbon capture materials are a crucial part of a range of technologies, alongside renewables and energy efficiency solutions, that can help reduce the amount of CO2 we release into the atmosphere.

“We show that small epoxy molecules typically found in glues can stick larger ones together to make effective carbon capture materials potentially useful to tackle climate change,” said Dr Enrico Andreoli, lead of the research study now subject of a paper published in Chemistry of Materials.

Dr Louise Hamdy, first author of the paper, added “We’ve developed a new approach to making an effective CO2 capture material from a widely studied CO2-reactive polyamine by reaction with an industrially mass-produced epoxy resin. This material shows very high CO2 uptake and could potentially be used to capture CO2 from industrial flue gas streams or from the air, relieving us from some of the worst effects of global warming.”

Current CO2 capture technologies need to be significantly advanced. Major challenges include materials cost, capacity, CO2-selectivity, regeneration, robustness and stability to water. Solid CO2 capture materials composed of polyamines supported on alumina or silica have emerged as promising carbon capture materials.

However, rather than follow suit, the researchers at ESRI cross-linked the polyamine into a solid by using epoxy resin – constituting just one-tenth of the mass of the material – maximising the CO2-reactive component and avoiding the use of a support. “This confirms the validity of my original idea of using cross-linking as an alternative to bulky supports,” said Andreoli.

The cross-linked material modified with a hydrophobic additive captured almost 20% of its weight in pure CO2 at 90 °C. This finding confirmed a previous hypothesis that the introduction hydrophobic groups can disrupt the internal structure of the material to promote CO2 uptake by the polyamine.

The additive not only increased the amount of captured CO2 but did so at a lower temperature. Hamdy commented, “This finding is significant as it proves that through the introduction of additives, we can fine tune these materials for optimum performance at specific working temperatures.”

Experiments revealed the functionalised sample to be highly selective for CO2 over nitrogen (N2), showing negligible uptake of N2. Selectivity was further explored by testing the material performance under flue gas-like conditions. This revealed that the sample could capture 9.5% of its weight in CO2 under a dilute CO2 stream of 10% CO2/90% N2 at 90 °C in only 15 minutes.

On subjecting the material to repetitive capture cycles, increasing the temperature to 155 °C under pure CO2 for 5 minutes to regenerate, the material showed no loss of capacity for 29 cycles, testament to the robustness of the material.

The functionalised material also performed exceptionally well under humid conditions – often a huge challenge for many CO2 sorbent solids. At 25 °C, in pure CO2, the pre-hydrated material was able to capture an impressive 23.5%. This opens up the possibility of this material being developed for capture of CO2 directly from the air.

“This research is defining a new and promising direction to economical and effective carbon capture materials. Our institute has a strong focus on developing and deploying new technologies in the field of carbon capture, utilisation, and storage. This paper is evidence of the level of our expertise,” said Professor Andrew Barron, founder and director of ESRI.

###

This research was carried out with support from FLEXIS and RICE, both part-funded by the European Regional Development Fund (ERDF) through the Welsh Government, and the Welsh Government Sêr Cymru II Fellowship Program.

NOTES TO EDITORS:

Barron is the Sêr Cymru Chair of Low Carbon Energy and Environment at Swansea, and Professor Emeritus of Chemistry at Rice University (Houston USA). Andreoli is an Associate Professor and head of the carbon capture and utilisation group at Swansea. Hamdy is a post-doctoral researcher at Swansea and lead author of the paper. Other co-authors are Dr Russell J. Wakeham and Dr Marco Taddei, both Marie Sk?odowska-Curie Cofund Fellows at Swansea at the time of the study.

Swansea University is a world-class, research-led, dual campus university offering a first class student experience and has one of the best employability rates of graduates in the UK.

The University has the highest possible rating for teaching – the Gold rating in the Teaching Excellence Framework (TEF) in 2018 and was commended for its high proportions of students achieving consistently outstanding outcomes.

Swansea climbed 14 places to 31st in the Guardian University Guide 2019, making us Wales’ top ranked university, with one of the best success rates of graduates gaining employment in the UK and the same overall satisfaction level as the Number 1 ranked university.

The 2014 Research Excellence Framework (REF) 2014 results saw Swansea make the ‘biggest leap among research-intensive institutions’ in the UK (Times Higher Education, December 2014) and achieved its ambition to be a top 30 research University, soaring up the league table to 26th in the UK.

The University is in the top 300 best universities in the world, ranked in the 251-300 group in The Times Higher Education World University rankings 2018. Swansea University now has 23 main partners, awarding joint degrees and post-graduate qualifications.

The University was established in 1920 and was the first campus university in the UK. It currently offers around 350 undergraduate courses and 350 postgraduate courses to circa 20,000 undergraduate and postgraduate students.

The University has ambitious expansion plans as it moves towards its centenary in 2020 and aims to continue to extend its global reach and realise its domestic and international potential.

Swansea University is a registered charity. No.1138342. Visit http://www.

When reporting this story, please use Swansea University hyperlinks.

For more information:

Kevin Sullivan,Swansea University Public Relations Office

Tel: 01792 513245, [email protected]

http://www.

http://www.

Media Contact

Kevin Sullivan

[email protected]

Related Journal Article

http://dx.