Credit: Dr Abdolhossein Naghizadeh, University of Johannesburg.

Fly ash generated by coal-fired power stations is an environmental headache, creating groundwater and air pollution from vast landfills and ash dams. Some of the waste product can be repurposed into geopolymer concrete, such as pre-cast heat-cured elements for structures.

However, a critical durability problem has been low resistance to extreme alkali attack. Researchers at the University of Johannesburg have found that high temperature heat-treatment (HTHT) can reduce this harmful mechanism in fly ash geopolymer concrete by half.

“In a previous study, we found that fly ash geopolymer concrete can be vulnerable under extreme alkaline conditions. The recommendation from the study, was that this material should not be employed in structures that are exposed to highly alkaline mediums, such as some chemical storage facilities.

“The findings of our new study show that the alkali resistance of geopolymer concrete can be significantly improved by exposing it to an evaluated temperature, optimally 200 degrees Celsius,” says Dr Abdolhossein Naghizadeh.

The study forms part of Naghizadeh’s doctoral research at the Department of Civil Engineering Science at the University of Johannesburg.

Extreme alkali medium

In the research published in Case Studies in Construction Materials, blocks of fly ash geopolymer mortars were variously heat-cured at 100, 200, 400 or 600 degrees Celsius for 6 hours. These were then immersed in water, a medium alkali medium or an extreme alkali medium; and stored at 80 degrees Celsius for 14 days or 28 days, depending on the performance measurement.

(The prolonged heat-curing for 28 days was conducted to compare the results with those obtained by the other studies, which employed the same curing regime. This long-term curing is suitable for research purposes, but not recommended for actual construction. The medium alkali medium was a 1M NaOH solution. The extreme alkali medium was a 3M NaOH solution.)

“The hardened blocks heat-cured at 200 degrees, and then immersed in the extreme alkali medium (the “200/3M” blocks), maintained about 50% residual strength at 22.6 MPa upon alkali attack. The blocks heat-cured at the other temperatures maintained much lower residual strengths at 10.3 – 14.6 MPa,” says Naghizadeh.

“The 200/3M blocks immersed in extreme alkali medium displayed only limited fine cracking indicating low expansion, compared to the others which displayed severe cracking. Leaching of silicone and aluminium was lowest for the 200/3M blocks.

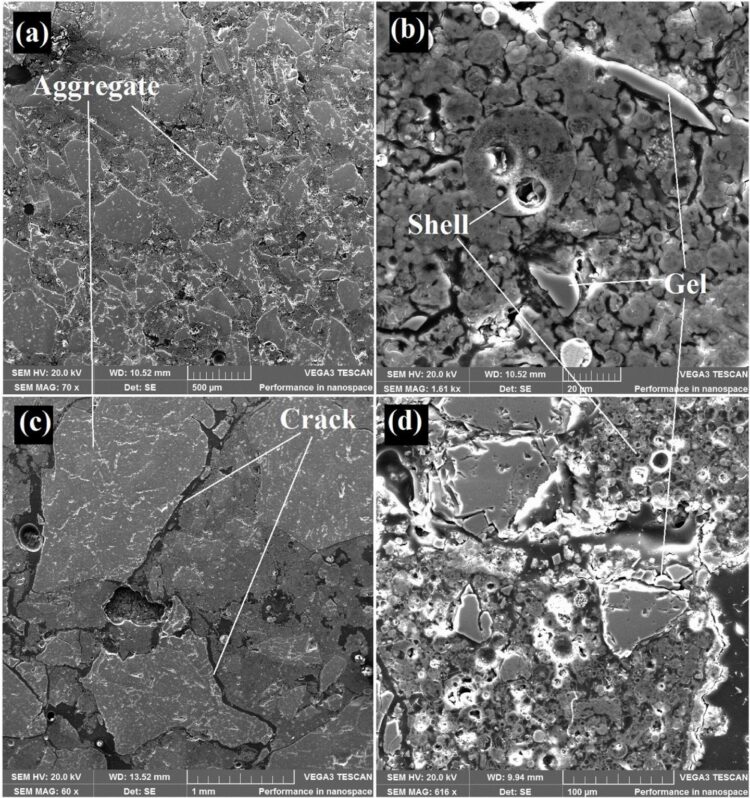

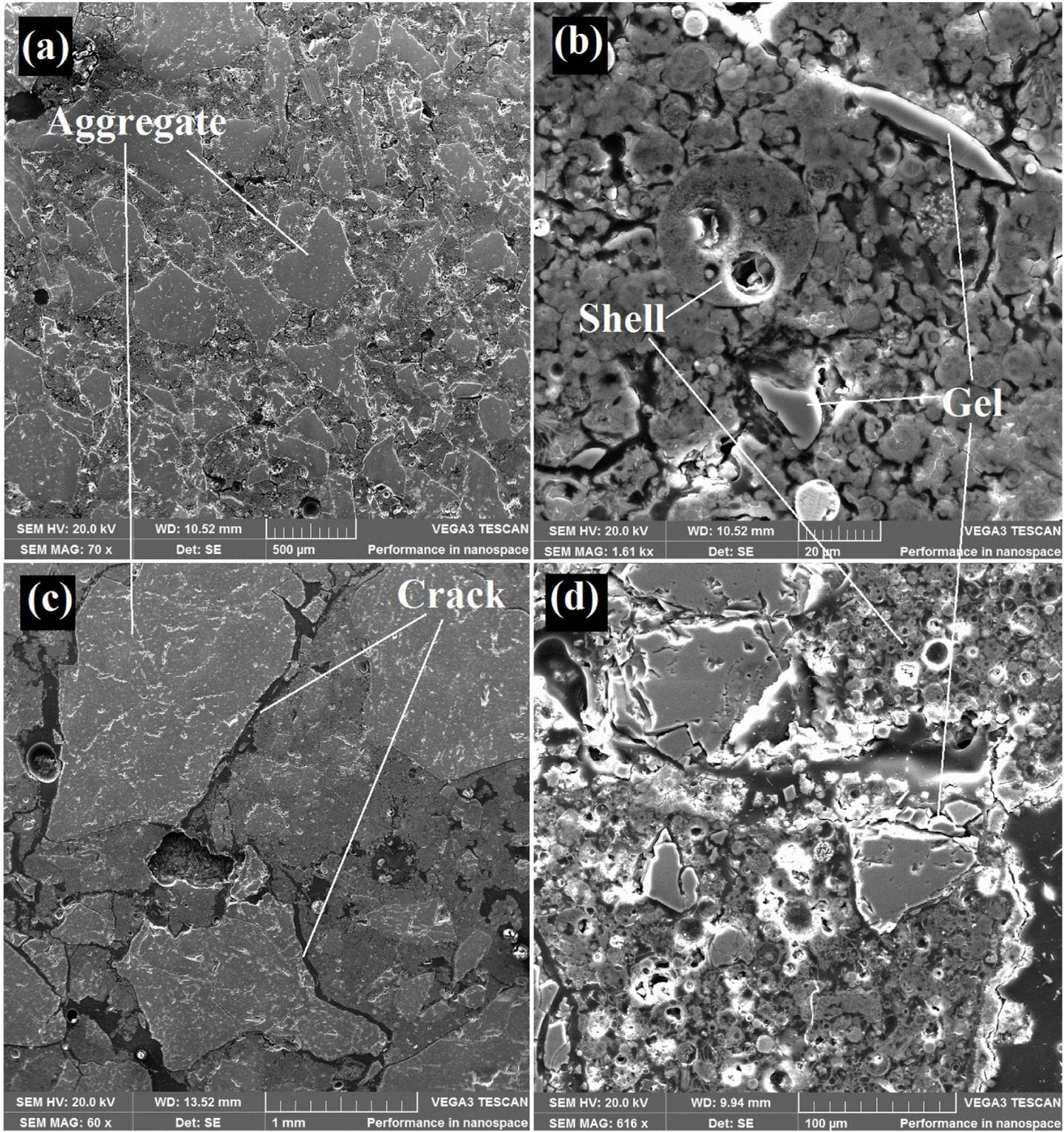

“X-ray diffraction showed that crystalline minerals, albite and sillimanite, formed in the binder phase of 200/3M blocks. Scanning electron microscope images of the 200/3M binders show the presence of a gel-like substance, characteristic of alkali attack. The heat-curing significantly reduced in the intensity of the attack but could not prevent it,” he says.

“The High Temperature Heat Treatment (HTHT) at 200 degrees created this effect by inhibiting the dissolution of unreacted fly ash particles within the hardened geopolymer concrete matrix. However, the HTHT also reduced the compressive strength for these blocks by 26.7%.”

Best used as precast

Fly ash geopolymer binders exhibit remarkable durability properties. Among these are high resistance to alkali-silica reaction; superior acid resistance; and high resistance to fire, low carbonation and limited sulfate attack, says Naghizadeh.

Fly ash geopolymer cement is suitable mostly for precast concrete manufactured at a factory or workshop. The reason is that strength development in geopolymer cement mixtures is generally slow under ambient temperatures.

This makes heat-curing necessary or essential for early strength gain. The practical methods established for heat-curing pre-cast Ordinary Portland cement (OPC) can be adapted for this.

This makes fly ash geopolymers suitable for precast concrete elements such as beams or girders for buildings and bridges, railway sleepers, wall panels, hollow core slabs, and concrete pipes.

For regular fly ash geopolymer concrete, a 24-hour period of heating at 60-80 degrees Celsius would be enough to achieve sufficient strength. This curing regime (temperature and duration) is common in cement industry, which is also used for some Portland cement concretes.

Although the use of geopolymer cement is growing every year, its application is still very small compared to OPC. Geopolymer has been employed as the binder in residential structures, bridges, and runways mostly in European countries, China, Australia, and the USA.

A new generation cement

Since the middle of the 18’th century, OPC has been used extensively to produce concrete. Its durability performance is well understood and its long-term behaviour can be predicted.

However, a new generation of cement is emerging as a suitable alternative to OPC in certain applications. These geopolymer cements (or geopolymer binders) have a nature and microstructure totally different from OPC.

A starting material used for geopolymer binder needs to be rich in alumina and silicate contents. On this criterion, multiple industrial waste or by-products qualify – such as rice husk ash, palm oil fuel ash and coal power plant fly ash.

However fly ash has two advantages for use as a geopolymer cement, says Naghizadeh.

Firstly, fly ash is available in millions of tons globally, also in developing countries. Repurposing fly ash as construction material can potentially reduce some of its environmental impacts. Currently, it is disposed of in vast ash dams and landfills close to coal-fuelled power plants, which generate air and ground-water pollution.

The second advantage for fly ash as starting material for geopolymer cement is its chemical composition. Typically, fly ash is rich enough in reactive silicon and aluminium oxides, which results in a better geopolymerization.

This in turn yields a binder with superior mechanical, physical and durability properties compared to the geopolymer concretes made using other waste products containing alumino-silicates.

More complex mix design

When designing a building, the engineer needs to ensure that the concrete used in the structure will have the expected strength for the service life. However, the physical and mechanical properties of concrete and other construction materials can change over time. Such changes can influence the material performance over the service life span of the construction.

Generally, an OPC concrete mixture includes cement, water and aggregate. The civil engineer develops an OPC mix design using specific proportions of these three ingredients for the intended structure.

“For fly ash-based geopolymer concrete activated by sodium silicate and sodium hydroxide, mix design is more complex than for OPC,” says Naghizadeh.

“More parameters are involved: the amounts of fly ash, sodium silicate, sodium hydroxide, water, and aggregate; as well as the concentration of sodium hydroxide; the proportion and quality of glass within the alkali.”

Fly ash from ash dams

In South Africa, research about using fly ash as a geopolymer cement is limited, says Prof Stephen Ekolu. Ekolu is a co-author of the study and former Head of the School of Civil Engineering and the Built Environment at University of Johannesburg.

“The existing research about fly ash geopolymer concrete uses fly ash supplied directly from power stations. Further research is needed about using fly ash from landfills and ash dams, technically referred to as “bottom ash” to produce geopolymer cement.

“The biggest research questions are issues of material quality, mix design, and developing the technology to allow curing at ambient conditions rather than the current practice of curing at elevated temperatures. Once these three scientific issues have been resolved, fly-ash and indeed most other forms of geopolymer cements can be better placed as OPC replacements worldwide,” says Ekolu.

Not a concrete extender

Currently, a small amount of fly ash is used as a common cement extender. In South Africa that amount is 10% of the 36 million tons produced annually. It is mixed with clinker to produce Pozzolanic Portland Cement (PPC).

Though fly ash is used as a common OPC extender, fly ash-based geopolymer concrete (FA-GC) is not combined with OPC-based concrete.

The reason is that the hydration process of OPC is completely different from the geopolymerization reaction of FA-GC. Also, OPC-based concrete and geopolymer concrete each requires a different curing condition.

Different production than OPC

The major phases in OPC production are the calcination and grinding processes.

Unlike OPC, geopolymer production does not require these phases. Fly ash-based geopolymer binders consist of two components: The fly ash and an alkali activator. Usually, fly ash is used as produced in the power station, with no need for further treatment.

Alkali activator solutions such as sodium silicate and sodium hydroxide are also extensively produced in the industry. These are used for multiple purposes, such as detergent and textile production.

“Greener” concrete

“The long-term durability of geopolymer cement under different environmental conditions needs further research. Also, the construction industry globally lacks technical knowledge of the production of geopolymers. To employ geopolymer binders, engineers, technicians and construction workers need training to design and produce geopolymer concrete mix designs with the required properties,” says Naghizadeh.

“There is no doubt that production of Portland cement needs to be limited in future, due to its huge environmental impacts. This includes about 5-8% global anthropogenic carbon-dioxide emissions into the atmosphere, which contributes to climate change,” adds Ekolu.

Several studies, including those from the University of Johannesburg, have shown that fly ash geopolymer can exhibit superior, or similar properties to Portland cement. This makes it a suitable alternative to replace Portland cement in certain applications.

Moreover, the availability of fly ash worldwide, especially in developing countries, provides an opportunity to produce more economic concrete “greener” than Ordinary Portland Cement, from the viewpoint of potential repurposing of a problematic waste product.

###

Written by Ms Therese van Wyk and Dr Abdolhossein Naghizadeh.

INTERVIEWS: For email interviews or questions, contact Dr Naghizadeh at [email protected].

For interviews via mobile phone / Skype / Zoom with Dr Naghizadeh, contact Ms Therese van Wyk at [email protected] or +27 71 139 8407 (mobile) in Johannesburg, UTC + 2.

Dr Naghizadeh’s doctoral research was partly funded by the Centre of Applied Research and Innovation in the Built Environment (CARINBE) at the University of Johannesburg.

Media Contact

Therese van Wyk

[email protected]

Related Journal Article

http://dx.