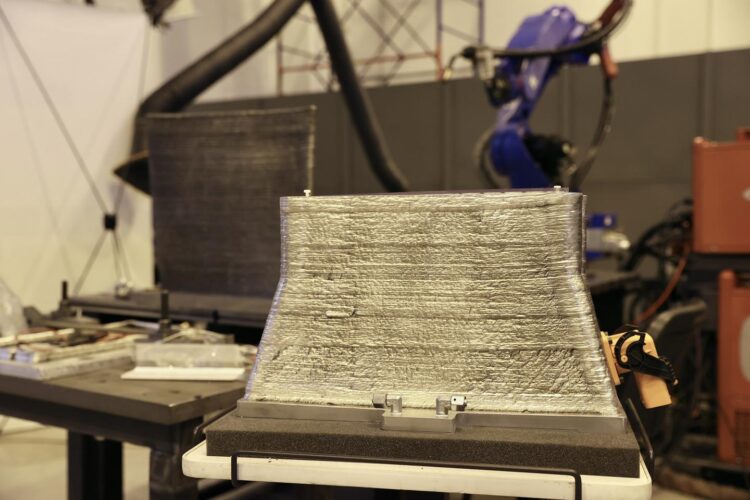

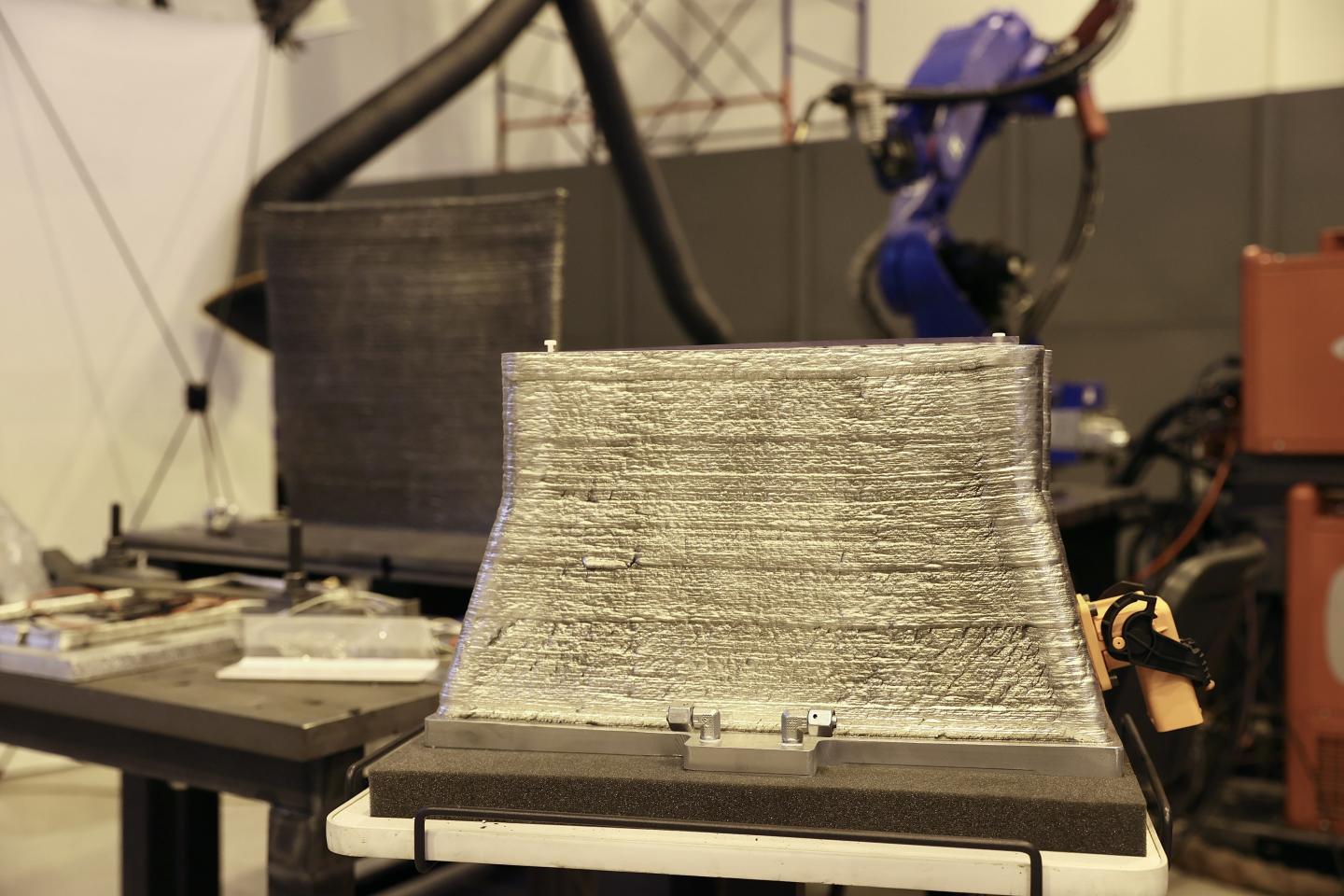

The radiator was developed using friction stir welding technology

Credit: Peter the Great St.Petersburg Polytechnic University

Researchers from Peter the Great St.Petersburg Polytechnic University (SPbPU) invented a durable and compact radiator for lithium-ion batteries, which in the future can be used for electric vehicles. The radiator was developed using friction stir welding technology.

“The development of the electric transport industry stimulates the search for new solutions in the field of rechargeable batteries with special requirements for energy consumption, weight, dimensions, and safety. These requirements are increasing every year. Its fulfillment can be achieved only by the introduction of new manufacturing technologies. For example, not the most noticeable, but an important part of such a battery is the cooling system. Thus this radiator should be compact, lightweight, and at the same time durable. To create such radiator, we used aluminum alloys and also applied friction stir welding technology” says Fedor Isupov, engineer of the Laboratory of Light Materials and Structures SPbPU.

The scientist explained that the material for the radiator was chosen due to its lightness and strength. However, if creating a cooling system made of aluminum using conventional methods (for example arc welding) the radiator wouldn’t be able to meet the requirements (in particular, in terms of dimensions).

“We can’t achieve the required compactness using the traditional methods. The welding of dissimilar aluminum alloys, which is used to create the radiator, is quite complicated. The seam at the junction of the sheets will be very fragile. Friction stir welding helps to avoid the defects inherent in fusion welding. It also speeds up and reduces the cost of the process. Also, thus it possible to obtain solid overlap joints, which are better than the one made by conventional welding, ” the scientist noted.

The obtained radiator has several functions. First of all, it plays the role of the battery bottom. Also, it is used not only to cool the battery but in low-temperature conditions, the heat is supplied through the radiator to heat the batteries; a special control system has been developed to regulate this process.

Researchers of St. Petersburg Polytechnic University developed the first sample of the radiator, and soon, they plan to test this cooling system.

According to the engineer, currently, in Russia, the friction stir welding of various materials is actively introduced in manufacturing: for example, for the construction of train and tram car; in the field of aviation and aerospace industry. It is also used for household appliances (for example, the Apple monitors).

###

Media Contact

Raisa Bestugina

[email protected]