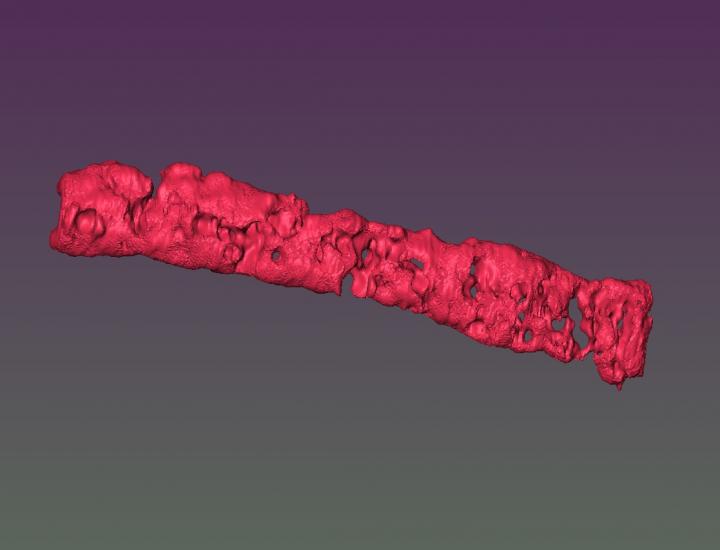

Credit: Ozbolat laboratory, Penn State

Micropores in fabricated tissues such as bone and cartilage allow nutrient and oxygen diffusion into the core, and this novel approach may eventually allow lab-grown tissue to contain blood vessels, according to a team of Penn State researchers.

“One of the problems with fabrication of tissues is that we can’t make them large in size,” said Ibrahim T. Ozbolat, associate professor of engineering science and mechanics. “Cells die if nutrients and oxygen can’t get inside.”

Inside cells also do not differentiate if the chemical cocktail that triggers stem cells to differentiate does not reach them. A porous structure allows both nutrients and other fluids to circulate.

The researchers are trying a novel approach and creating tissue building blocks with micropores. They consider this an alternative to vascularization — growing blood vessels in the tissue — and call the outcome porous tissue strands.

The researchers are starting with stem cells derived from human fat and mixing them with sodium alginate porogens. Derived from seaweed, sodium alginate can be printed into tiny particles that, when dissolved, leave behind tiny holes — pores — in the fabric of the tissue. The team uses the mixture to 3D print strands of undifferentiated tissue. They can then combine the strands to form patches of tissue.

When the researchers expose the tissue to the chemical cocktail, it turns the stem cells into specific cells, in this case bone or cartilage. Because of the pores, the fluid can flow to all of the stem cells.

The researchers report in a recent issue of Biofabrication that the strands maintain 25 percent porosity and have pore connectivity of 85 percent for at least three weeks.

By 3D printing strands next to and atop each other as shown in their previous work, the strands self-assemble to form patches of tissue.

“These patches can be implanted in bone or cartilage, depending on which cells they are,” said Ozbolat. “They can be used for osteoarthritis, patches for plastic surgery such as the cartilage in the nasal septum, knee restoration and other bone or cartilage defects.”

In some ways, cartilage is easier than bone because in the human body, cartilage does not have blood vessels running through it. However, some bone is naturally porous, and so porosity is valuable in replacing or repairing that bone. While currently only tiny patches can be made, these patches are easier to fabricate than growing artificial tissue on scaffolding.

The researchers are considering applying the same methods to muscle, fat and various other tissues.

###

Other researchers at Penn State include Yang Wu, postdoctoral fellow in engineering science and mechanics; Monika Hospodiuk, graduate student in agricultural and biological engineering; Hemanth Gudapati, graduate student in engineering science and mechanics; Thomas Neuberger, director, High Field Magnetic Resonance Imaging Facility; Srinivas Koduru, research technologist in the Department of Surgery; and Dino J. Ravnic, assistant professor of surgery, Penn State Cancer Institute. Also on the project was visiting scholar Weijie Peng, department of pharmacology, Nanchang University, China.

The National Science Foundation, the China Scholarship Council and the Jiangxi Association for Science and Technology supported this work.

Media Contact

A’ndrea Elyse Messer

[email protected]

814-865-9481

Related Journal Article

http://dx.