Physicists found out the structures in nanomaterials made of ceramic and graphene plates, in which cracks appear most frequently

Credit: Peter the Great St.Petersburg Polytechnic University

Physicists and materials scientists from Peter the Great St.Petersburg Polytechnic University (SPbPU) found out the structures in nanomaterials made of ceramic and graphene plates, in which cracks appear most frequently. The results of the first trial of the model, that describes the found regularity, were published in the Mechanics of Materials Journal. This model will help in creation of crack-resistant materials. The research was supported by the Russian Science Foundation grant.

Graphene is the lightest and strongest carbon modification. Moreover, it has a very high electrical conductivity. Because of these characteristics graphene is often included in the composition of new ceramic-based materials. Ceramics are resistant to high temperatures, and, if carbon modifications are added, the composites become multifunctional. In the future they can be used in production of flexible electronic devices, sensors, in construction and aviation.

It is known from many experimental studies of such composites that their mechanic characteristics are set by the graphene proportion in the composition and by the size of graphene plates allocated in the ceramic matrix. For example, in case of low graphene concentration high crack resistance was achieved with the help of long plates. However, in one of the recent experiments of synthesis of materials from alumina ceramics and graphene the opposite effect was shown: as the plates were bigger, the crack resistance was weaker. The researches from Saint Petersburg have developed a theoretical model that explains this paradox.

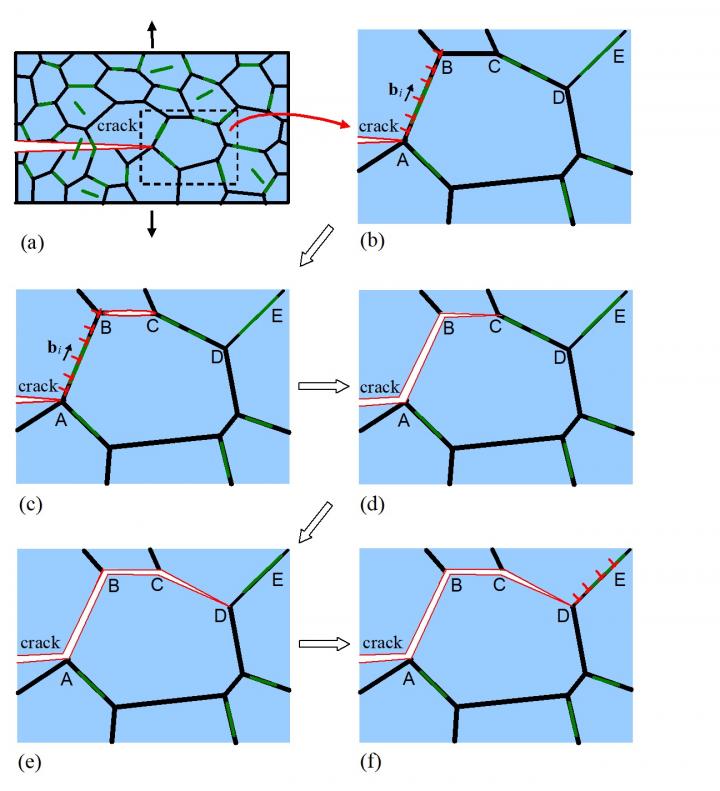

The SPbPU physicists of the of the Advanced Manufacturing Technologies Center of the National Technology Initiative (NTI) of Peter the Great St. Petersburg Polytechnic University supposed that the formation of cracks in the composites is connected with the boundaries of so-called ceramic grains – microscopic crystals that form the material. Graphene plates in the composites can be located both at the boundaries of ceramic grains and inside grains. In the course of the tensile deformation of nanocrystalline materials, the grains slide relative to each other, and the cracks spread over their boundaries. But why do graphene additions stop this process in some cases and not stop it in others? To find the answer, the scientists developed a mathematical model that takes into account the tensile load, the force of friction, elastic moduli of the composite, and the correlation between the dimensions of ceramic grains and graphene plates. With the help of the model the scientists computed the critical values of the stress intensity factor for three different composites. When these values were exceeded, cracks spread all over in the material. The composites varied in the size of ceramic grains (from 1.23 to 1.58 micrometers) and the length and width of graphene plates (from 193 to 1070 and from 109 to 545 nanometers).

It was found that the closer the length of graphene plates to the length of grain boundary lines, the lower the critical value of the stress intensity factor. The value difference for different materials comes up to 20%. It is congruent to experimental data published earlier: just at close values of grain boundary length and the length of graphene plates the crack resistance of the material dropped. This implies that to make the material stronger, graphene plates must be substantially smaller in length that ceramic grains.

“The found regularity is valid for fine-grained ceramics, and, after all, by reducing the grain size, the creators of new composite materials add more functionality to them,” explains Alexander Sheinerman, Doctor of Physical and Mathematical Sciences, the head of research laboratory “The Mechanics of New Nanomaterials” of the Advanced Manufacturing Technologies Center of the National Technology Initiative NTI SPbPU. “Therewith, the effects of grain refinement can be contradictory, for example, the hardness rises, but the material becomes more fragile. Our model helps to pick the correlation of the graphene plate size and the size of grains, which provide better mechanic and functional characteristics.

###

Media Contact

Raisa Bestugina

[email protected]

Related Journal Article

http://dx.