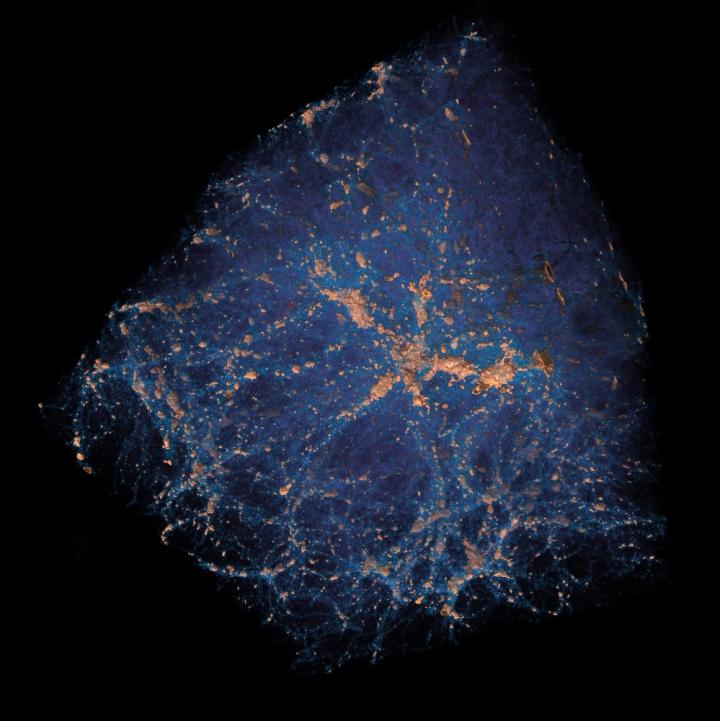

Credit: Joe Insely, Silvio Rizzi and HACC Team/Argonne National Laboratory

Computing–Virtual universes

Using Summit, the world’s most powerful supercomputer housed at Oak Ridge National Laboratory, a team led by Argonne National Laboratory ran three of the largest cosmological simulations known to date. They modeled nearly two trillion particles in each simulation to trace matter distribution and generated a total of eight petabytes of data. These “virtual universes” will enable scientists to compare next-generation telescope observations with some of today’s reigning physics theories, including the impact of dark energy and the mass of neutrinos, once thought to be massless, on the structural formation of the universe. “This data will be very valuable for our studies with the Large Synoptic Sky Survey Telescope,” said Katrin Heitmann, Argonne physicist and computational scientist and an Oak Ridge Leadership Computing Facility Early Science user. Currently under construction, the telescope will image about 37 billion stars and galaxies, and supercomputing simulations are preparing the project for the monumental data analysis required. [Contact: Katie E. Jones, (865) 241-2679; [email protected]]

Image: https:/

Caption: ORNL’s Summit supercomputer was used to simulate and visualize the matter distribution of a virtual universe, with the gold color representing the highest densities. Credit: Joe Insely, Silvio Rizzi and HACC Team/Argonne National Laboratory

Materials–Mussel-like stickiness

Scientists at Oak Ridge National Laboratory have developed a new, stretchy plant-derived material that outperforms the adhesiveness of the natural chemical that gives mussels the ability to stick to rocks and ships. This bio-based material composed of lignin, the substance that gives plants sturdiness, and epoxy can self-heal and elongate up to 2,000%. Researchers developed a unique method to extract a specific form of lignin, a by-product of biofuels production. “We targeted a component of lignin that is naturally rich in hydroxyl groups,” said ORNL’s Amit Naskar. “The molecular structure creates a super-sticky, highly elastic material that can heal quickly, where broken, through hydrogen bonding.” This extracted lignin shows promise to replace dopamine for a range of industrial applications including coatings, glues and hydrogels. The results, published in ACS Macro Letters, demonstrate new potential for a small, but high-value portion of the lignin waste stream from biorefineries and the pulp and paper industry. [Contact: Kim Askey, (865) 576-2841; [email protected]]

Image: https:/

Caption: Researchers developed a new material using epoxy mixed with a form of lignin naturally rich in hydroxyl groups that can self-heal if sliced and elongate up to 2,000%. Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy

Manufacturing–Not so heavy metal

A novel additive manufacturing method developed by researchers at Oak Ridge National Laboratory could be a promising alternative for low-cost, high-quality production of large-scale metal parts with less material waste. Researchers printed thin metal walls using a closed-loop, feedback-controlled technique to provide uniform flat beads and layers at a desired height. The system automatically regulates the printing process, creating stable properties within the metal deposit and producing a high-quality build throughout the part. “We achieved a precise geometry for the components by using real-time feedback sensors to correct for abnormalities,” ORNL’s Andrzej Nycz said. “Because metal printed walls represent the basic building blocks of parts manufactured with big area additive manufacturing, we expect the same stable properties to hold for parts printed with complex geometries.” The large-scale metal additive manufacturing method deposits materials at high rates, which allows for multiple metal feedstocks. The team’s results were published in Applied Sciences. [Contact: Jennifer Burke, (865) 576-3212; [email protected]]

Image: https:/

Caption: ORNL researchers printed thin metal walls using large-scale metal additive manufacturing, a wire-arc process that demonstrated stability, uniformity and precise geometry throughout the deposition. The method could be a viable option for large-scale additive manufacturing of metal components. ORNL collaborated with industry partner Lincoln Electric. Credit: Oak Ridge National Laboratory, U.S. Dept. of Energy

Nuclear–Scale and speed

In a step toward advancing small modular nuclear reactor designs, scientists at Oak Ridge National Laboratory have run reactor simulations on ORNL supercomputer Summit with greater-than-expected computational efficiency. The team’s experiments tracked 100 billion particle histories–which are collections of unique, individual neutron interactions that occur within a reactor core–on Summit’s sophisticated GPU-based architecture, taking advantage of the supercomputer’s full capacity. ORNL scientist Steven Hamilton said the Monte Carlo radiation transport codes used in the simulation ran 30 to 40 times faster and with four to five times greater efficiency on Summit versus the same experiments performed on Titan. Results of the simulations, detailed in Annals of Nuclear Energy, factor into part of an Exascale Computing Project called ExaSMR. “Our hope is to more accurately predict how the reactors will behave before they are built,” Hamilton said. “This research instills more confidence that the reactor is going to behave exactly as predicted.” [Contact: Sara Shoemaker, (865) 576-9219; [email protected]]

Image: https:/

Caption: ORNL researchers simulated radiation transport in small modular reactors, or SMRs, by running Monte Carlo codes on Summit, the world’s most powerful supercomputer. The simulations factor into part of an Exascale Computing Project called ExaSMR. Credit: Steven Hamilton/Oak Ridge National Laboratory, U.S. Dept. of Energy

###

Media Contact

Sara Shoemaker

[email protected]

Original Source

https:/

Related Journal Article

http://dx.