Rice University bioengineers lead effort to print scaffolds to heal bone and cartilage

Credit: Jeff Fitlow/Rice University

HOUSTON – (March 28, 2019) – Bioscientists are moving closer to 3D-printed artificial tissues to help heal bone and cartilage typically damaged in sports-related injuries to knees, ankles and elbows.

Scientists at Rice University and the University of Maryland reported their first success at engineering scaffolds that replicate the physical characteristics of osteochondral tissue – basically, hard bone beneath a compressible layer of cartilage that appears as the smooth surface on the ends of long bones.

Injuries to these bones, from small cracks to pieces that break off, can be painful and often stop athletes’ careers in their tracks. Osteochondral injuries can also lead to disabling arthritis.

The gradient nature of cartilage-into-bone and its porosity have made it difficult to reproduce in the lab, but Rice scientists led by bioengineer Antonios Mikos and graduate student Sean Bittner have used 3D printing to fabricate what they believe will eventually be a suitable material for implantation.

Their results are reported in Acta Biomaterialia.

“Athletes are disproportionately affected by these injuries, but they can affect everybody,” said Bittner, a third-year bioengineering graduate student at Rice, a National Science Foundation fellow and lead author of the paper. “I think this will be a powerful tool to help people with common sports injuries.”

The key is mimicking tissue that turns gradually from cartilage (chondral tissue) at the surface to bone (osteo) underneath. The Biomaterials Lab at Rice printed a scaffold with custom mixtures of a polymer for the former and a ceramic for the latter with imbedded pores that would allow the patient’s own cells and blood vessels to infiltrate the implant, eventually allowing it to become part of the natural bone and cartilage.

“For the most part, the composition will be the same from patient to patient,” Bittner said. “There’s porosity included so vasculature can grow in from the native bone. We don’t have to fabricate the blood vessels ourselves.”

The future of the project will involve figuring out how to print an osteochondral implant that perfectly fits the patient and allows the porous implant to grow into and knit with the bone and cartilage.

Mikos said the collaboration is a great early success for the Center for Engineering Complex Tissues (CECT), a National Institutes of Health center at Maryland, Rice and the Wake Forest School of Medicine developing bioprinting tools to address basic scientific questions and translate new knowledge into clinical practice.

“In that context, what we’ve done here is impactful and may lead to new regenerative medicine solutions,” Mikos said.

###

Co-authors of the paper are Rice graduate student Brandon Smith, postdoctoral researcher Luis Diaz-Gomez, undergraduate Carrigan Hudgins, Anthony Melchiorri, associate director of the Biomaterials Lab, and David Scott, the Noah Harding Professor of Statistics; and John Fisher, CECT director and Fischell Family Distinguished Professor and chair of the University of Maryland’s Fischell Department of Bioengineering. Mikos is the Louis Calder Professor of Bioengineering and a professor of chemical and biomolecular engineering, of chemistry and of materials science and nanoengineering.

The National Institutes of Health and the RegenMed Development Organization supported the research.

Read the abstract at https:/

This news release can be found online at https:/

Follow Rice News and Media Relations via Twitter @RiceUNews.

Related materials:

Mikos Research Group: https:/

Biomaterials Lab: bml.rice.edu

Tissue Engineering and Biomaterials Laboratory (Fisher lab): https:/

Rice Department of Bioengineering: https:/

George R. Brown School of Engineering: https:/

Center for Engineering Complex Tissues: https:/

Images for download:

https:/

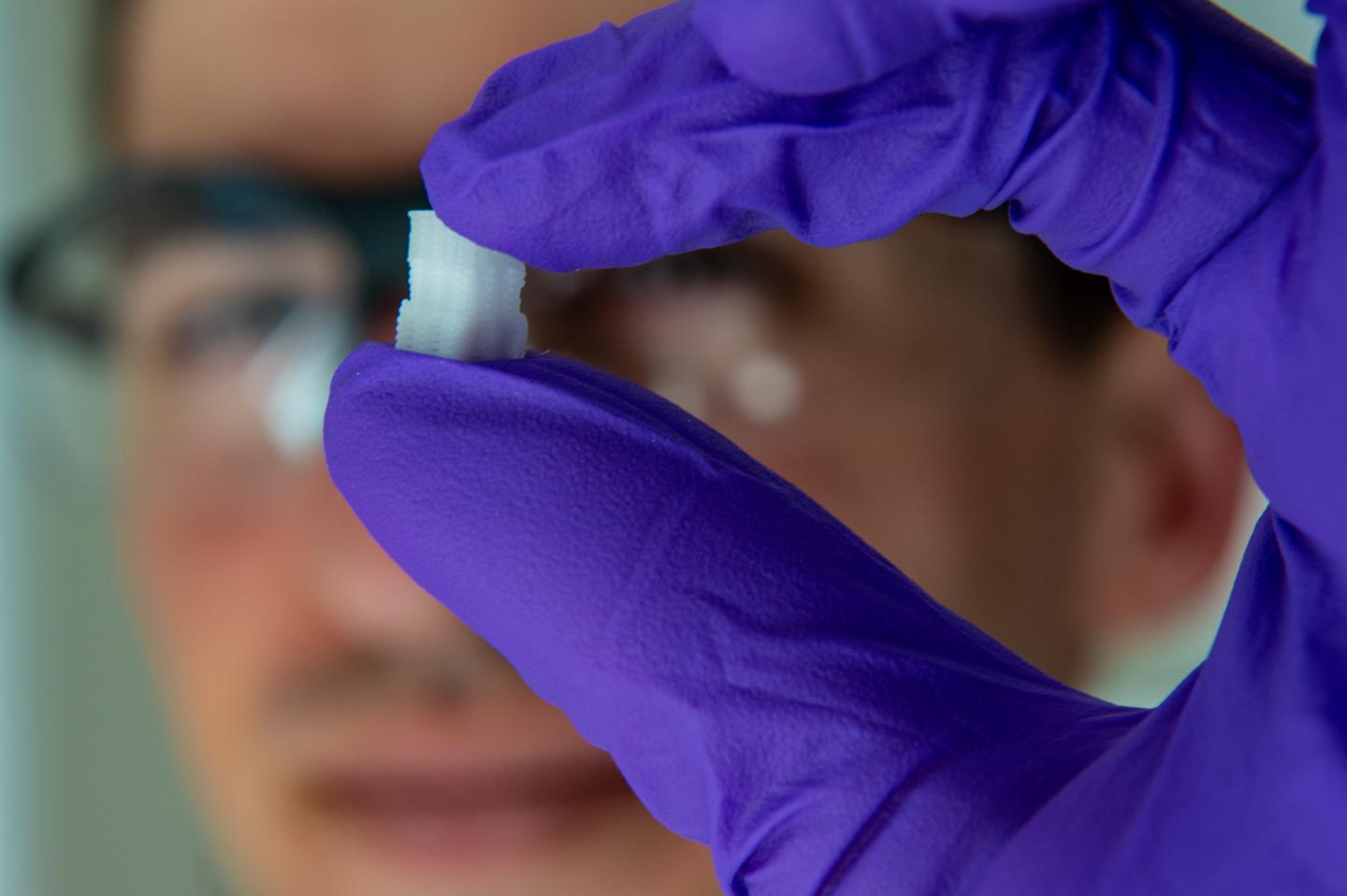

Rice University graduate student Sean Bittner holds a 3D-printed scaffold created to help heal osteochondral injuries. The initial study is a proof-of-concept to see if printed structures can mimic the gradual transition from smooth, compressible cartilage to hard bone at the end of long bones. (Credit: Jeff Fitlow/Rice University)

https:/

Rice University graduate student Sean Bittner holds a sample of a 3D-printed scaffold that may someday help heal osteochondral injuries of the kind often suffered by athletes. The material mimics the gradient structure of cartilage to bone found at the end of long bones. (Credit: Jeff Fitlow/Rice University)

https:/

Rice University graduate student Sean Bittner holds a 3D-printed scaffold created to help heal osteochondral injuries. The initial study is a proof-of-concept to see if printed structures can mimic the gradual transition from smooth, compressible cartilage to hard bone at the end of long bones. (Credit: Jeff Fitlow/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 2 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

###

David Ruth 713-348-6327 [email protected]

Mike Williams 713-348-6728 [email protected]

Media Contact

Mike Williams

[email protected]

Related Journal Article

http://dx.