HOUSTON – (Sept. 2, 2016) – Flakes of graphene welded together into solid materials may be suitable for bone implants, according to a study led by Rice University scientists.

The Rice lab of materials scientist Pulickel Ajayan and colleagues in Texas, Brazil and India used spark plasma sintering to weld flakes of graphene oxide into porous solids that compare favorably with the mechanical properties and biocompatibility of titanium, a standard bone-replacement material.

The discovery is the subject of a paper in Advanced Materials.

The researchers believe their technique will give them the ability to create highly complex shapes out of graphene in minutes using graphite molds, which they believe would be easier to process than specialty metals.

“We started thinking about this for bone implants because graphene is one of the most intriguing materials with many possibilities and it’s generally biocompatible,” said Rice postdoctoral research associate Chandra Sekhar Tiwary, co-lead author of the paper with Dibyendu Chakravarty of the International Advanced Research Center for Powder Metallurgy and New Materials in Hyderabad, India. “Four things are important: its mechanical properties, density, porosity and biocompatibility.”

Tiwary said spark plasma sintering is being used in industry to make complex parts, generally with ceramics. “The technique uses a high pulse current that welds the flakes together instantly. You only need high voltage, not high pressure or temperatures,” he said. The material they made is nearly 50 percent porous, with a density half that of graphite and a quarter of titanium metal. But it has enough compressive strength — 40 megapascals — to qualify it for bone implants, he said. The strength of the bonds between sheets keeps it from disintegrating in water.

The researchers controlled the density of the material by altering the voltage that delivers the highly localized blast of heat that makes the nanoscale welds. Though the experiments were carried out at room temperature, the researchers made graphene solids of various density by raising these sintering temperatures from 200 to 400 degrees Celsius. Samples made at local temperatures of 300 C proved best, Tiwary said. “The nice thing about two-dimensional materials is that they give you a lot of surface area to connect. With graphene, you just need to overcome a small activation barrier to make very strong welds,” he said.

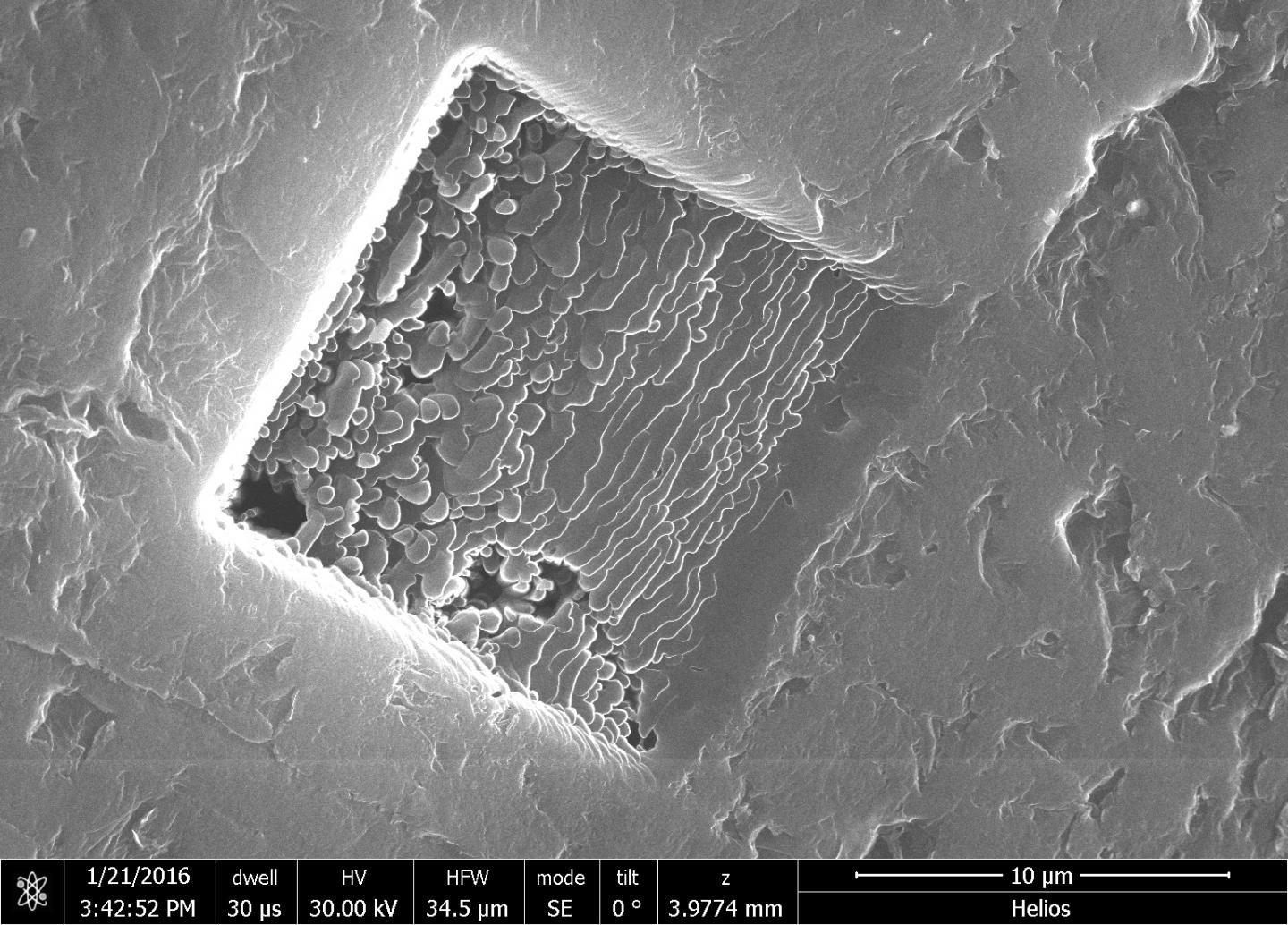

With the help of colleagues at Hysitron in Minnesota, the researchers measured the load-bearing capacity of thin sheets of two- to five-layer bonded graphene by repeatedly stressing them with a picoindenter attached to a scanning electron microscope and found they were stable up to 70 micronewtons. Colleagues at the University of Texas MD Anderson Cancer Center successfully cultured cells on the material to show its biocompatibility. As a bonus, the researchers also discovered the sintering process has the ability to reduce graphene oxide flakes to pure bilayer graphene, which makes them stronger and more stable than graphene monolayers or graphene oxide.

“This example demonstrates the possible use of unconventional materials in conventional technologies,” Ajayan said. “But these transitions can only be made if materials such as 2-D graphene layers can be scalably made into 3-D solids with appropriate density and strength.

“Engineering junctions and strong interfaces between nanoscale building blocks is the biggest challenge in achieving such goals, but in this case, spark plasma sintering seems to be effective in joining graphene sheets to produce strong 3-D solids,” he said.

###

Co-authors of the paper are graduate student Sruthi Radhakrishnan of Rice and at MD Anderson; researcher Soumya Vinod and graduate student Sehmus Ozden of Rice; Pedro Alves da Silva of the State University of Campinas, Brazil, and the Federal University of ABC, Santo Andre, Brazil; Autreto Cristano Woellner and Professor Douglas Galvão of the State University of Campinas, Brazil; Sanjit Bhowmick and Syed Asif of Hysitron Inc. of Minneapolis; and Sendurai Mani of MD Anderson. Ajayan is chair of Rice’s Department of Materials Science and NanoEngineering, the Benjamin M. and Mary Greenwood Anderson Professor in Engineering and a professor of chemistry.

The research was supported by the Department of Defense, the U.S. Air Force Office of Scientific Research and its Multidisciplinary University Research Initiative, the Sao Paulo Research Foundation, the Center for Computational Engineering and Sciences at Unicamp, Brazil, and the Government of India Department of Science and Technology.

Read the abstract at http://onlinelibrary.wiley.com/doi/10.1002/adma.201603146/full

This news release can be found online at http://news.rice.edu/2016/09/02/3-d-graphene-has-promise-for-bio-applications/

Follow Rice News and Media Relations via Twitter @RiceUNews

Video:

[youtube https://www.youtube.com/watch?v=9itxVFu_p5U?feature=oembed&w=640&h=480]

A molecular dynamics simulation shows how graphene oxide layers stack when welded by spark plasma sintering. The presence of oxygen molecules at left prevents the graphene layers from bonding, as they do without oxygen at right. (Credit: Ajayan Group/Rice University and Galvão group/Unicamp, Brazil)

Related materials:

Ajayan Research Group: http://ajayan.rice.edu

Rice Department of Materials Science and NanoEngineering: https://msne.rice.edu

Images for download:

http://news.rice.edu/files/2016/09/0906_BONE-1-WEB-1rfjnr7.jpg

Rice University materials scientists and their international colleagues created a form of 3-D graphene oxide with layers welded together at room temperature via spark plasma sintering. The material shows promise for biological applications. (Credit: Ajayan Group/Rice University)

http://news.rice.edu/files/2016/09/0906_BONE-2-WEB-22oacp6.jpg

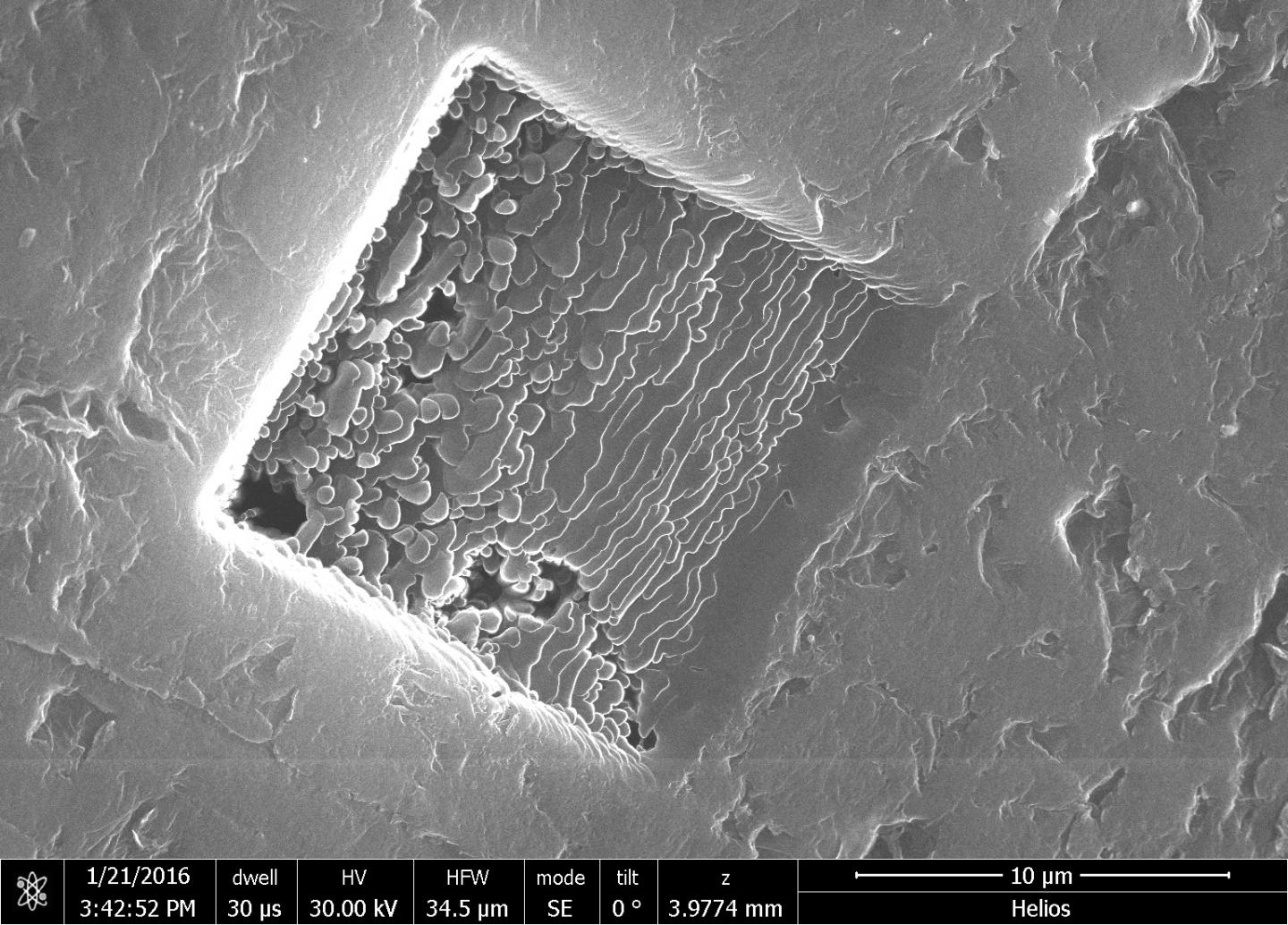

A focused ion beam microscope image shows 3-D graphene layers welded together in a block. The material is biocompatible and its material properties meet the standards necessary for consideration as a bone implant, according to researchers at Rice University. (Credit: Ajayan Group/Rice University)

http://news.rice.edu/files/2016/09/0906_BONE-3-WEB-1xccx3p.jpg

A pellet of three-dimensional reduced graphene oxide developed by an international team led by Rice University shows the potential to replace titanium as a material for bone implants. (Credit: Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,910 undergraduates and 2,809 graduate students, Rice’s undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for best quality of life and for lots of race/class interaction by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance. To read “What they’re saying about Rice,” go to http://tinyurl.com/RiceUniversityoverview.

David Ruth

713-348-6327

[email protected]

Mike Williams

713-348-6728

[email protected]

Media Contact

Mike Williams

[email protected]

713-348-6728

@RiceUNews

http://news.rice.edu

The post 3-D graphene has promise for bio applications appeared first on Scienmag.