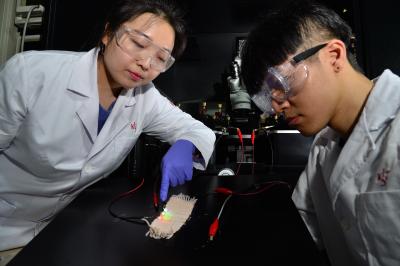

Transistors connected with twisted electrodes maintain functionality even after being bent and washed over 1,000 times and can activate LED or detect electrocardiogram signals

Credit: Korea Institute of Science and Technology(KIST)

With the wearable electronic device market having firmly established itself in the 21st century, active research is being conducted on electronic textiles,1 which are textiles (e.g. clothing) capable of functioning like electronic devices. Fabric-based items are flexible and can be worn comfortably all day, making them the ideal platform for wearable electronic devices.

The research team of Dr. Jung-ah Lim of the Korea Institute of Science and Technology (KIST, president: Byung-gwon Lee) announced that it has developed a fibrous transistor2 that has a fiber structure, giving it the characteristics of a textile while allowing it to be inserted into clothing and retain an adequate level of functionality even after being washed.

Existing technology involves physically attaching a solid electronic device (sensor, etc.) to the surface of clothing or using conductive textiles to connect various devices, with little to no attention paid to the wearer’s comfort. Existing thread-type transistors are made by depositing a flat transistor onto a single conductive thread. Electrodes made in this manner require a high voltage in order to be activated, but the low current that is generated is often insufficient to activate display devices (LED, etc.). Until now, it was also difficult to create electronic circuits through contact with other devices (for woven fabrics) or to apply a protective layer to the transistor to allow for washing.

The transistor developed by the KIST research team is made by connecting twisted electrodes. Using this structure, the team was able to adjust the length of the threads and thickness of the semiconductor to obtain currents over 1,000-times higher than those possible using existing transistors, even at low voltages (below -1.3V).

Through tests, Lim’s team confirmed that even after bending the transistor or winding it around a cylindrical object over 1,000 times (with a resulting thickness of approximately 7 millimeters), it maintained a performance level of over 80 percent. The team also announced that the performance level remained adequate even after washing the transistor in water containing detergent. The team was also able to activate an LED device with the transistor inserted between the threads of clothing and measure electrocardiogram signals through signal amplification.

Lim said, “The results of this study point to a new device structure that can overcome the limitations of current electronic textiles, including low current, high activation voltage, and low resilience to washing. We expect that our study will contribute to the development of even smarter wearable products in the future, including next-generation wearable computers and smart clothing that can monitor vital signs.”

###

This study was conducted with support from the Ministry of Science and Technology (minister: Young-min Yoo) as a project of KIST and the National Research Foundation of Korea. The outcomes of this study were published in the most recent online issue (Issue 31, No. 23) of Advanced Materials (IF: 21.950, top 1.020% of JCR sector), a renowned international journal on materials.

1. Electronic textile: a fabric that can conduct electricity while also maintaining the unique characteristics of the fabric itself

2. Transistor: a device that acts as a switch by controlling current and/or voltage flow, making it a key element in the creation of electronic textiles

Media Contact

Dohyun Kim

[email protected]

Related Journal Article

http://dx.