Researchers have developed a completely new method for twisting atomically thin materials, paving the way for applications of ‘twistronics’ based on tunable 2D materials

Credit: Luojun Du et al. Aalto University

Two-dimensional (2D) materials, which consist of a single layer of atoms, have attracted a lot of attention since the isolation of graphene in 2004. They have unique electrical, optical, and mechanical properties, like high conductivity, flexibility and strength, which makes them promising materials for such things as lasers, photovoltaics, sensors and medical applications.

When a sheet of 2D material is placed over another and slightly rotated, the twist can radically change the bilayer material’s properties and lead to exotic physical behaviours, such as high temperature superconductivity – exiting for electrical engineering; nonlinear optics – exciting for lasers and data transmission; and structural super-lubricity- a newly discovered mechanical property which researchers are only beginning to understand. The study of these properties has given birth to a new field of research called twistronics, so-called because it’s a combination of twist and electronics.

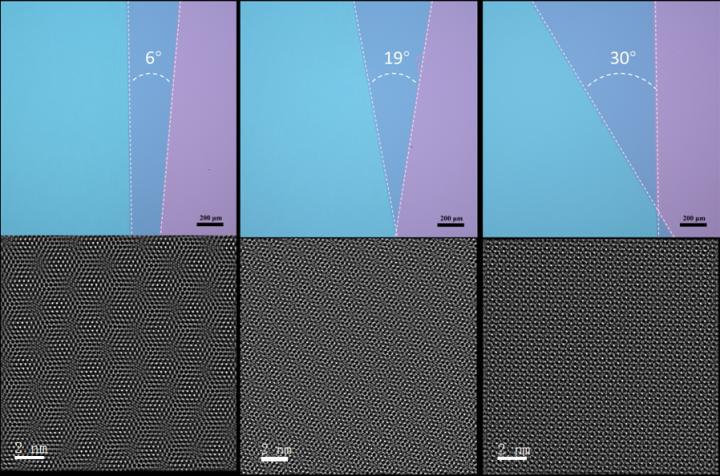

Aalto University’s researchers collaborating with international colleagues have now developed a new method for making these twisted layers on scales that are large enough to be useful, for the first time. Their new method for transferring single-atom layers of molybdenum disulfide (MoS2) allows researchers to precisely control the twist angle between layers with up to a square centimetre in area, making it record-breaking in terms of size. Controlling the interlayer twist angle on a large scale is crucial for the future practical applications of twistronics.

‘Our demonstrated twist method allows us to tune the properties of stacked multilayer MoS2 structures on larger scales than ever before. The transfer method can also apply to other two-dimensional layered materials’, says Dr Luojun Du from Aalto University, one of the lead authors of the work.

A significant advancement for a brand-new field of research

Since twistronics research was introduced only in 2018, basic research is still needed to understand the properties of twisted materials better before they find their ways to practical applications. The Wolf Prize in Physics, one of the most prestigious scientific awards, was awarded to Profs. Rafi Bistritzer, Pablo Jarillo-Herrero, and Allan H. MacDonald this year for their groundbreaking work on twistronics, which indicates the game-changing potential of the emerging field.

Previous research has demonstrated that it is possible to fabricate the required twist angle by transfer method or atomic force microscope tip manipulation techniques in small scales. The sample size has usually been in the order of ten-microns, less than the size of a human hair. Larger few-layer films have also been fabricated, but their interlayer twist angle is random. Now the researchers can grow large films using an epitaxial growth method and water assistant transfer method.

‘Since no polymer is needed during the transfer process, the interfaces of our sample are relatively clean. With the control of twist angle and ultra-clean interfaces, we could tune the physical properties, including low-frequency interlayer modes, band structure, and optical and electrical properties’, Du says.

‘Indeed, the work is of great significance in guiding the future applications of twistronics based on 2D materials’, adds Professor Zhipei Sun from Aalto University.

The results were published in Nature Communications.

###

M. Liao et.al., Precise control the interlayer twist angle of large scale MoS2 homostructures.

https:/

Media Contact

Luojun Du

[email protected]

Related Journal Article

http://dx.