Credit: JAIST

Researchers at Japan Advanced Institute of Science and Technology (JAIST): graduate student Kulisara Budpud, Assoc. Prof. Kosuke Okeyoshi, Dr. Maiko Okajima and, Prof. Tatsuo Kaneko reveal a unique polysaccharide fiber in a twisted structure forming under drying process which showed spring-like behavior. The spring-like behavior of twisted structures is practically used as a reinforced structure in a vapor-sensitive film with millisecond-scale response time. This work is published in Small Full Paper titled “Vapor-Sensitive Materials from Polysaccharide Fibers with Self-Assembling Twisted Microstructures”.

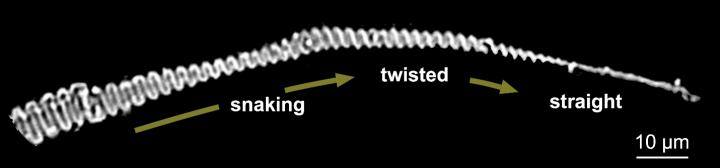

Polysaccharides play a variety of roles in nature, including molecular recognition and water retention. Still, there is a lack of study in vitro microscale structures of polysaccharides because of the difficulties in regulating self-assembled structures. If the self-assembled structures of these natural polysaccharides can be reconstructed in vitro, it will lead not only to an increased understanding of the morphological changes involved in polysaccharide self-assembly in water but also to the development of a new class of bio-inspired materials, which exhibit regulated structures on a nanometer scale. In this research, it is demonstrated that a cyanobacterial polysaccharide named sacran, can hierarchically self-assemble as twisted fibers from nanoscale to microscale with diameters of ?1 μm and lengths >800 μm. this is remarkably larger than polysaccharides previously reported. Unlike other rigid fibrillar polysaccharides such as cellulose, the sacran fiber is capable of flexibly transforming into two-dimensional snaking and three-dimensional twisted structures at an evaporative air-water interface (Fig.1). This twisted sacran fiber behaves like a mechanical spring under a humid environment.

To optimize the condition of the twisted structure is formed by controlling drying speeds. Actually, the drying speed and the capillary force are the dominant factors in creating these formations. To show the potential use of this spring-like polysaccharide fibers, a crosslinked polysaccharide film is prepared as a vapor-sensitive material and the effects of the microfiber’s spring behaviors in an environment with humidity gradient are demonstrated (Fig.2). The film reversibly and quickly switched between flat and bent states within 300-800 ms. This repulsive motion displayed by the film is caused by the snaking and twisted structures of the fibers responding to the change of moisture. The sacran film shows a fast response to the water drop retreating, changing from the bent state to the flat state. Because the extended sacran fibers have extension stress like a spring, the network could quickly release water by shrinking. As a result, the bent film becomes flat immediately. Thus, the snaking and twisted fiber network enable millisecond bending and stretching responses to changes in local humidity.

From the simple method, JAIST researchers could create unique micro-spring from natural polysaccharide which is practically used as a vapor-sensitive material. Besides, by introducing functional molecules into the microfiber, it would be possible to prepare a variety of soft actuators responding to other changes in the external environment, such as light, pH, and temperature. The method for preparing vapor sensors developed by this study not only improves understanding of how the motion of self-assembled structures responds to stimuli. But also contributes toward the design of environmentally adaptive materials with a high potential for sustainable use.

###

“Vapor-Sensitive Materials from Polysaccharide Fibers with Self-Assembling Twisted Microstructures”, Kulisara Budpud, Kosuke Okeyoshi*, Maiko Okajima and, Tatsuo Kaneko*, Small, 2020 (DOI: 10.1002/smll.202001993)

Media Contact

Kosuke Okeyoshi

[email protected]

Related Journal Article

http://dx.