Credit: SUTD

Currently, a wide range of applications has been demonstrated using microfluidic devices made of silicone rubbers (such as polydimethylsiloxane (PDMS)), including materials syntheses, separation and sorting, diagnostics and bioanalysis. The reason for the popularity of PDMS in academic laboratories is the simplicity of the fabrication and well-characterised properties of PDMS. However, PDMS are not compatible with strong organic solvents; they quickly swell silicone-based materials. To this end, microfluidic channels possessing chemical and solvent compatibility would be desirable.

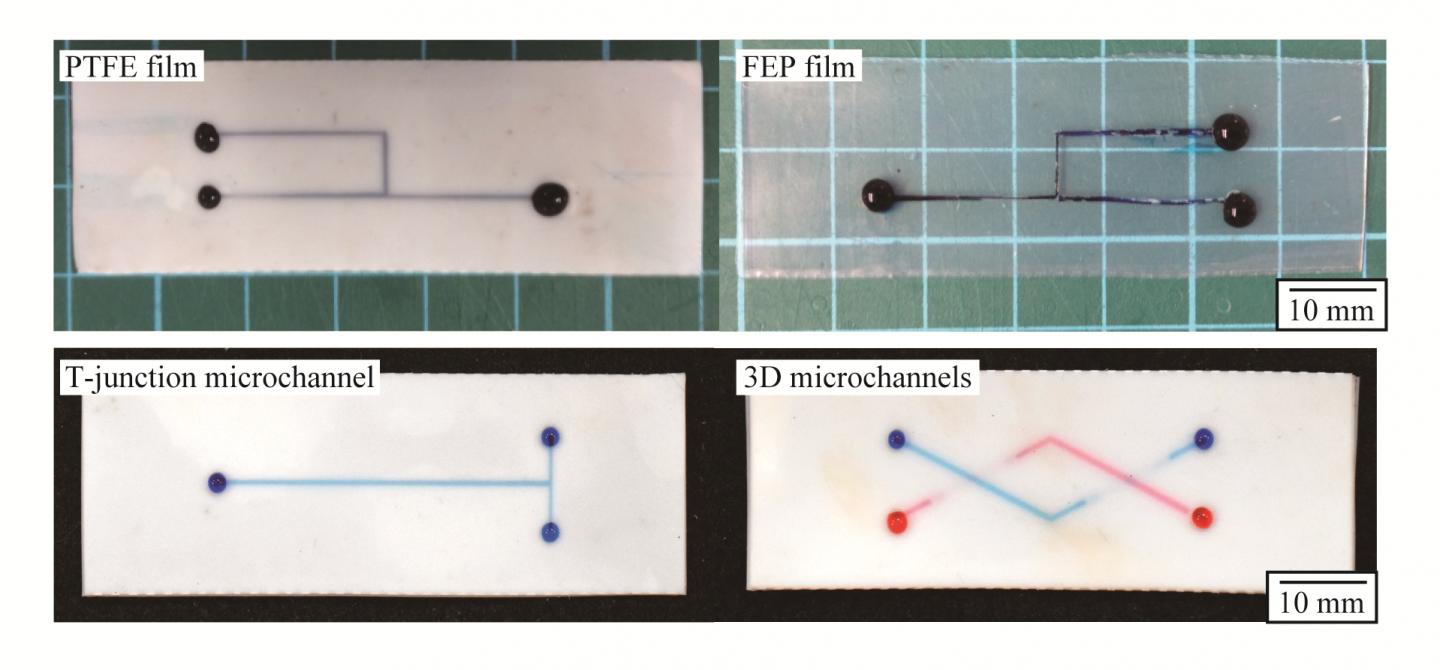

A research team from the Singapore University of Technology and Design (SUTD), led by Assistant Professor Michinao Hashimoto, developed a simple method to fabricate microchannels using fluoropolymers – a general class of polymers including TeflonTM that are highly inert against the exposure to chemicals and solvents. The research group applied xurography (i.e. a method of digital fabrication to cut films with a motion-controlled razor blade to create stencils) to cut films of fluoropolymers and heat-press to from microchannels. It takes less than 1 hour to make microchannels from designing to assembling using this method.

The research team has identified proper conditions of heat pressing (i.e. temperature, time and pressure) for two common fluoropolymers: polytetrafluoroethylene (PTFE) and fluorinated ethylene propylene (FEP). Furthermore, the team confirmed the fluoropolymer microfluidic channels’ resistance to a set of organic solvents that would not be compatible with typical devices fabricated in PDMS.

Principal investigator, Dr Hashimoto said: “This work is the first demonstration to bridge the gap to rapidly fabricate microfluidic channels using fluoropolymers. Microchannels consisting of fluoropolymers can be useful in performing organic syntheses of materials and drugs as well as regulating adhesion of biological molecules, cells and bacteria. This method is extremely simple, and we believe it can be performed by literally any researcher–including non-engineers–for various applications that require the inert and non-reactive properties of the channels.”

This new prototyping technique has been published in Biomicrofluidics, a reputable journal focused on research in unique microfluidic and nanofluidic techniques. An SUTD visiting students (Takuma Hizawa) and two postdoctoral researchers (Atsushi Takano, Pravien Parthiban) participated in this project together with the senior authors (Prof. Eiji Iwase, Waseda University, Japan, and Prof. Patrick Doyle, MIT, USA).

###

Media Contact

Melissa Koh

[email protected]

65-649-98742

Related Journal Article

http://dx.