SUTD collaborates with universities in Singapore and China to shine light on HEA manufacturing processes and inspire further research in this emerging field

Credit: SUTD

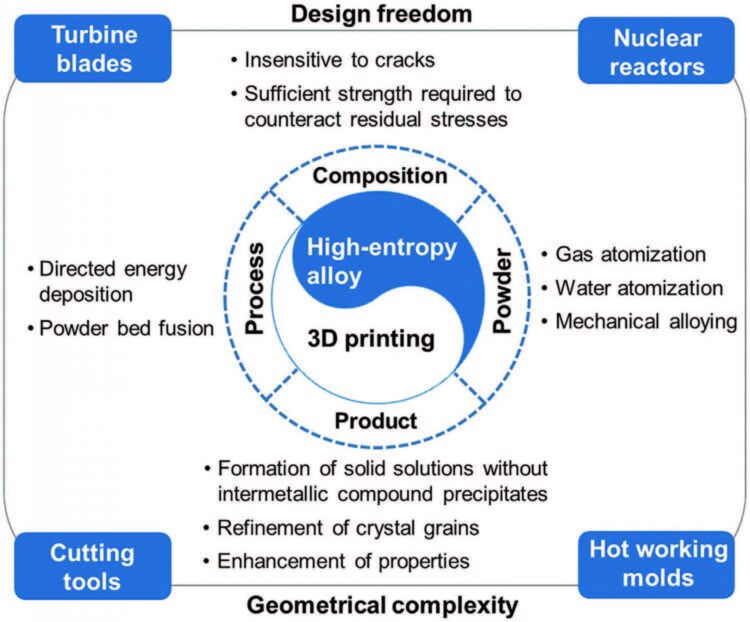

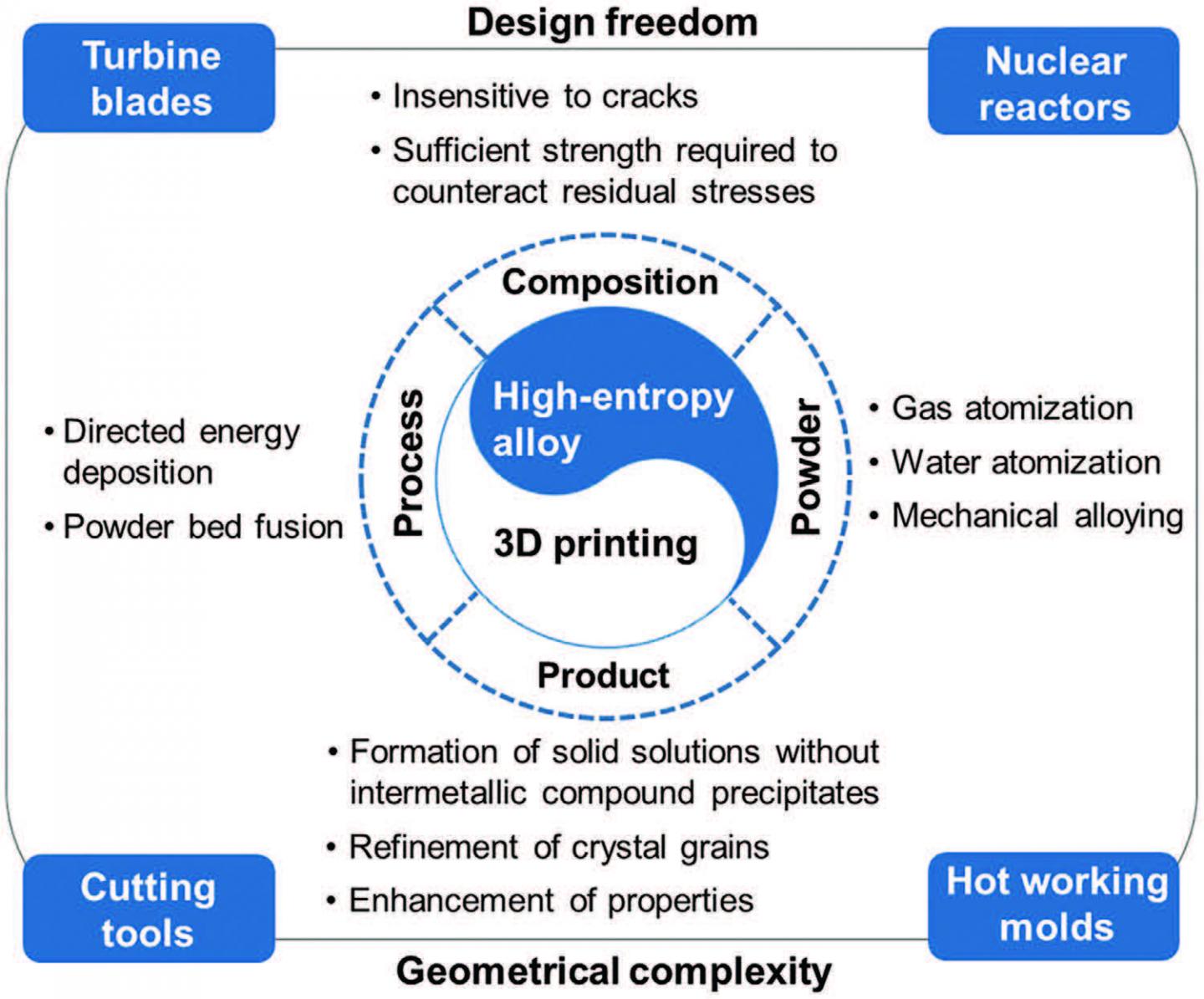

High-entropy alloys (HEAs) are at the frontier of the metal materials community. They are used as alternative materials in the production of high-temperature turbine blades, high-temperature molds and dies, hard coatings on cutting tools or even components of 4th generation nuclear reactors.

By screening proper combinations of HEAs’ constituent elements and regulating their proportions, HEAs can exhibit remarkable mechanical properties at high temperatures and display exceptional strength, ductility and fracture toughness at cryogenic temperatures.

Meanwhile, the development of HEAs for 3D printing has also been advancing rapidly, ramping up great potential for the manufacturing of such geometrically complex HEA products with desirable performances.

However, there is a lack of comprehensive understanding on the 3D printing of HEAs. To tackle this issue, researchers from Singapore University of Technology and Design (SUTD), Nanyang Technological University (NTU), Huazhong University of Science and Technology and Hunan University collaborated to publish a thorough review of the recent achievements on 3D printing of HEAs (refer to image). The study was published in Advanced Materials.

The review paper includes the production processes for HEA powders, 3D printing processes for HEA products, and the microstructure, mechanical properties, functionalities and potential applications of the printed products.

“3D printing of HEAs has been undergoing explosive growth in the academia and will gain extensive interest from industry. In our review, laser-based directed energy deposition, selective laser melting and electron beam melting are validated for their applicability to print various high-quality HEA products. It allows for a combination of material selection, design and manufacturing freedoms for lightweight, customizable and non-assembly required products,” explained lead author Professor Chua Chee Kai from SUTD.

“The ultrafast cooling rates of certain 3D printing techniques are expected to prevent the formation of undesirable intermetallic compounds in HEA products, thereby enhancing their mechanical properties. The different cooling rates of these printing processes would induce substantial variations in both the microstructures and macroscopic performances of the products,” said first author Dr Han Changjun from NTU.

“We believe that this paper serves as a valuable comprehensive review to deepen our understanding of the 3D printing of HEAs by focusing on its unique merits. Hopefully, more researchers would be encouraged to explore this highly interesting field,” added corresponding author Associate Professor Zhou Kun from NTU.

###

Media Contact

Jessica Sasayiah

[email protected]

Related Journal Article

http://dx.