Credit: Yuichiro Nagatsu/ TUAT

The current global supply of crude oil is expected to meet demand through 2050, but there may be a few more drops to squeeze out. By making use of a previously undesired side effect in oil recovery, researchers have developed a method that yields up to 20% more heavy oil than traditional methods.

Tokyo University of Agriculture and Technology (TUAT) team published their results on August 24 in Energy & Fuels, a journal of the American Chemical Society.

The researchers focused on heavy oil recovery, which involves extracting highly viscous oil stuck in porous rocks.

“The total estimated volume of recoverable heavy oil is almost the same as the remaining light reserves in the world,” said paper author Yuichiro Nagatsu, associate professor in the Department of Chemical Engineering at TUAT. “With the depletion of light oil resources and rising energy demands, the successful recovery of heavy oil is becoming increasingly important.”

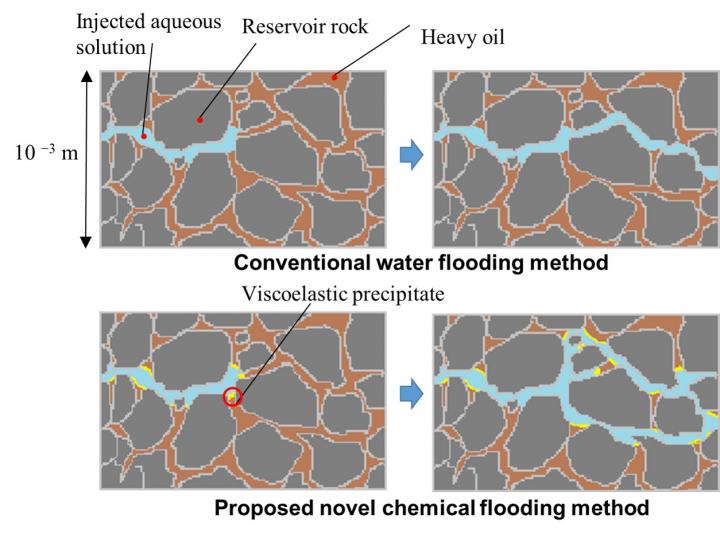

Generally, less than 10 % of heavy oil may be produced from the reservoirs by natural flow after drilling the well. To yield more oil, water may be injected into the reservoir to maintain pressure in order to keep the flow moving. Engineers may also make the water more alkaline by adding sodium hydroxide or sodium carbonate to help the oil flow better. Called chemical flooding, this process often fails to yield much heavy oil, as it is too thick for even the enriched water to sweep up. Heavy oil can also be made to flow more easily through heat, but that’s not a tangible solution for deep or thin reservoirs, according to Nagatsu.

“It is important to develop non-thermal chemical flooding for the recovery of heavy oil,” Nagatsu said. “The key problem of chemical flooding in heavy oil reservoirs is an inefficient sweep as a result of the low mobility of the oil.”

Because the viscosity of water and heavy oil differ so greatly, Nagatsu said, contemporary sweep methods are inefficient for heavy oil recovery.

To correct this inefficiency in chemical recovery, Nagatsu and his team injected calcium hydroxide into their model reservoir. The compound helps oil to flow more smoothly but is considered undesirable because it reacts with the oil to produce a metallic soap where the water and oil interface.

“The metallic soap behaves as a viscoelastic material in the pore and blocks the preferentially swept region and improves the sweep efficiency,” Nagatsu said.

The metallic soap stops the sweeping flow from moving into already swept areas, forcing the forward recovery of heavy oils locked deep in rocks and crevices. In experimental testing, the method yielded 55% of oil in the reservoir, compared to a 35% recovery using alkaline water and a 33% recovery using regular water. Nagatsu noted that this method is inexpensive, can be used in a range of temperatures and it does not require energy-consuming techniques to perform.

The researchers plan to study the effectiveness of this method across crude oil viscosity ranges and in different ranges of oil reservoir permeability in laboratory experiments before moving to field tests. They would also like to engage with industry to further develop the technology for practical application, Nagatsu said.

###

Other contributors include Kizuna Abe, Kaori Konmoto and Keiichiro Omori, all of whom are affiliated with the Department of Chemical Engineering at TUAT, Japan.

This work was supported by PRESTO, Japan Science and Technology (JST) Agency (25103004 “Phase Interfaces for Highly Efficient Energy Utilization”) for financial support.

For more information about the Nagatsu laboratory, please visit

http://web.

Original publication:

Chemical Flooding for Enhanced Heavy Oil Recovery via Chemical-Reaction-Producing Viscoelastic Material

Yuichiro Nagatsu*, Kizuna Abe, Kaori Konmoto, and Keiichiro Omori

Energy Fuels 2020, 34, 9, 10655-10665

https:/

*: corresponding author

About Tokyo University of Agriculture and Technology (TUAT):

TUAT is a distinguished university in Japan dedicated to science and technology. TUAT focuses on agriculture and engineering that form the foundation of industry, and promotes education and research fields that incorporate them. Boasting a history of over 140 years since our founding in 1874, TUAT continues to boldly take on new challenges and steadily promote fields. With high ethics, TUAT fulfills social responsibility in the capacity of transmitting science and technology information towards the construction of a sustainable society where both human beings and nature can thrive in a symbiotic relationship. For more information, please visit http://www.

Contact:

Yuichiro Nagatsu, Ph.D.

Associate Professor, Department of Chemical Engineering, TUAT, Japan

[email protected]

Media Contact

Yutaka Nibu, Ph.D.

[email protected]

Related Journal Article

http://dx.