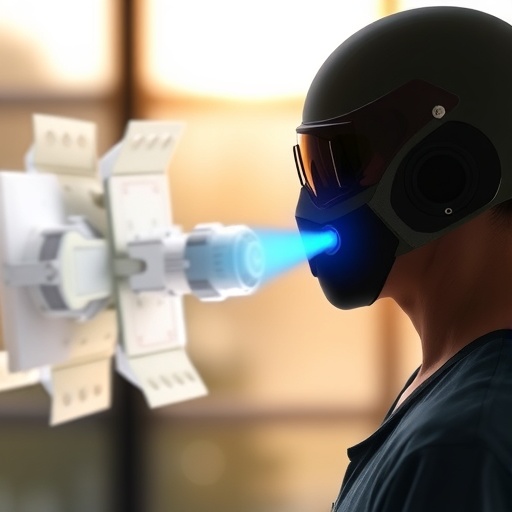

A groundbreaking innovation in the detection of hazardous gases promises to revolutionize environmental and security monitoring. Researchers have developed a low-cost, highly sensitive optoelectronic sensor array capable of identifying toxic gaseous compounds, including lethal nerve agents such as chlorosarin, with unprecedented speed and accuracy. This novel system utilizes a grid of microscale, color-changing silica particles embedded in a flexible paper substrate, offering a new frontier for portable and reliable gas detection technologies in diverse real-world conditions.

Traditional detection methods for poisonous gases often rely on electronic “noses,” complex devices engineered to recognize chemical vapors. These systems, while effective, face significant challenges including high production costs, intricate electronics requiring frequent maintenance, and vulnerability to humid or wet environments, which can impair sensor performance. Addressing these shortcomings, the research team introduced an optoelectronic approach wherein the sensing mechanism is based not on electronic circuits but on dyes that chemically interact with target gases, producing visible colorimetric changes.

Central to this innovation is the fabrication of a sensor array composed of multiple small silica microparticles, each impregnated with unique colorimetric dyes. When exposed to specific gases, these dyes undergo molecular interactions that alter their optical properties. This dynamic manifests as distinct shifts in color intensity and hue, effectively encoding the chemical identity and concentration of the analytes. By arranging these dye-loaded particles into a fixed pattern on a piece of adhesive paper, the researchers created a compact, lightweight “nose” that visually registers toxic gases.

.adsslot_jCdDq8EbtH{width:728px !important;height:90px !important;}

@media(max-width:1199px){ .adsslot_jCdDq8EbtH{width:468px !important;height:60px !important;}

}

@media(max-width:767px){ .adsslot_jCdDq8EbtH{width:320px !important;height:50px !important;}

}

ADVERTISEMENT

The manufacturing process of this sensor array is notable for its simplicity and affordability. The silica microparticles are soaked in 36 different solutions containing dyes that respond to various chemical stimuli. Upon drying, these microparticles are transferred onto adhesive paper using an embossing technique facilitated by a microwell plate. This method allows precise placement and uniform distribution of the sensing particles. To reinforce the delicate paper structure and ensure durability, a thin metal sheet is affixed beneath the paper, enabling the entire array to maintain integrity even under field conditions.

Performance evaluation of the sensor array involved exposure to a panel of 12 poisonous gases, each tested at two concentration levels. The resulting colorimetric patterns were captured photographically both before and after five minutes of gas exposure. Advanced image processing algorithms analyzed the differences in color and intensity, translating the visual data into chemical signatures. Impressively, the array achieved a 99% success rate in correctly identifying the type of toxic gas and a 96% accuracy in quantifying its concentration. Importantly, repeated testing showed that environmental humidity did not degrade sensor performance, highlighting robustness critical for outdoor and industrial applications.

This optoelectronic nose system has far-reaching implications beyond laboratory settings. Its low fabrication cost, estimated at approximately 20 cents per array, makes it accessible for widespread deployment. Such affordability is essential for monitoring air quality in sensitive environments such as chemical manufacturing plants, military zones, and urban centers vulnerable to industrial pollution or chemical accidents. Moreover, the adaptability of dye chemistry suggests the possibility of customizing sensor arrays to detect a broad spectrum of hazardous substances, elevating the utility of the device as a versatile chemical alert tool.

The integration of colorimetric silica microparticles into a self-adhesive paper medium also paves the way for handheld, portable detection devices. The research team’s next objective is to develop a prototype that combines the sensor array with compact imaging and processing electronics, enabling immediate readout and decision-making in the field. This innovation could empower first responders, security personnel, and environmental scientists with real-time data on chemical threats, potentially saving lives and mitigating environmental damage.

Critically, the optoelectronic sensor array circumvents many limitations inherent in electronic sensing systems. The elimination of complex circuitry reduces susceptibility to electromagnetic interference and allows stable operation across a wide range of environmental conditions, including high humidity and temperature fluctuations. The colorimetric response is also inherently intuitive, facilitating rapid assessment even without advanced instrumentation, which is valuable in emergency scenarios where time is essential.

The chemistry behind the sensor is rooted in sophisticated dye-nanoparticle interactions. Each dye is selected for its selective affinity and responsive optical properties upon binding with gaseous molecules or ions. The mesoporous silica microparticles provide a large surface area and protective matrix to host these dye molecules, optimizing sensitivity and response time. This design ensures that even trace amounts of toxic gas induce measurable color changes, enhancing early detection capabilities.

Exploring future directions, the modularity of this approach allows researchers to engineer sensor arrays tailored to specific chemical environments. By tuning the choice of dyes and their arrangement, it becomes feasible to create bespoke optoelectronic noses for detecting industrial solvents, environmental pollutants, or biological warfare agents. Such adaptability could transform chemical sensing across industries, fostering safer workplaces and communities.

Funding support for this research was provided by India’s Defence Research & Development Organization, underscoring the strategic importance of rapid, reliable chemical threat detection technologies. The collaboration and insights gained through this project exemplify the emerging intersection of materials science, analytical chemistry, and engineering in developing solutions to complex environmental challenges.

In summary, the development of a simple, cost-effective embossed colorimetric sensor array marks a significant advance in optoelectronic nose technology. By harnessing the color-shifting properties of dye-coated silica microparticles embedded in adhesive paper, researchers have established a novel platform for detecting poisonous gases with high precision and speed. As this technology progresses toward commercialization, it promises to enhance global capabilities in environmental monitoring, public safety, and chemical defense.

Subject of Research: Detection of poisonous gases using an optoelectronic colorimetric sensor array.

Article Title: “Simple and Cost-Effective Fabrication of Embossed Colorimetric Sensor Array for an Optoelectronic Nose via Integration of a Self-Adhesive Paper and Mesoporous Colorimetric Silica Microparticles”

News Publication Date: 21-Jul-2025

Web References: http://dx.doi.org/10.1021/acssensors.5c01026

References: ACS Sensors 2025, DOI: 10.1021/acssensors.5c01026

Image Credits: Adapted from ACS Sensors 2025, DOI: 10.1021/acssensors.5c01026

Keywords

Chemistry, Sensors

Tags: colorimetric dye sensing mechanismsenvironmental safety innovationsflexible sensor technologyhazardous gas monitoringlow-cost gas sensorsnerve agent detection advancementsoptoelectronic sensor arrayportable gas detection solutionsrapid color-changing sensorreal-time hazardous gas identificationsilica microparticles for gas detectiontoxic gas detection technology