Polysaccharide and protein-based coatings on metallic implants increase bone tendency to attach on implants, prevent loosening and bacterial invasion

Credit: Ahmet Engin Pazarçeviren

WASHINGTON, April 27, 2021 — Traffic accidents, tumor resections, and congenital diseases can cause significant trauma, which can lead to large bone deformations and/or bone loss. Although bone has some capacity to regenerate, large bone defects cannot be healed without major medical procedures.

In these situations, metallic implants are widely used, but the bioinertness of such implants poses a major challenge in bone tissue engineering. Bioinert metal implants lack bone integration, loosen over time, and may lead to adverse reactions around the area in which they are implanted.

In Biointerphases, by AIP Publishing, researchers from Middle East Technical University in Turkey showcase a variety of approaches that are alternatives to metallic implants and use natural polymer coatings to improve bone-implant integration, also known as osseointegration.

“We utilized a soft structure, which is very similar to human tissues, and placed this structure between human or animal bone and a metal surface,” said author Zafer Evis. “This serves as an interphase increasing bone tendency to attach on implants and prevent loosening or bacterial invasion.”

Establishing a strong and robust chemical interaction between a metal and a completely organic and natural polymer is a significant advancement in the field of bone tissue engineering. It opens a new era of applications with a broader range of modalities that can be applied in almost all hard tissue defects and traumas.

The research showcases several important findings. First, natural polymer coatings significantly improved metal electrochemical corrosion properties, and metals tend to resist corrosion after polymer coating. Second, polysaccharides and proteins can be successfully grafted onto metal surfaces without losing their biological nature.

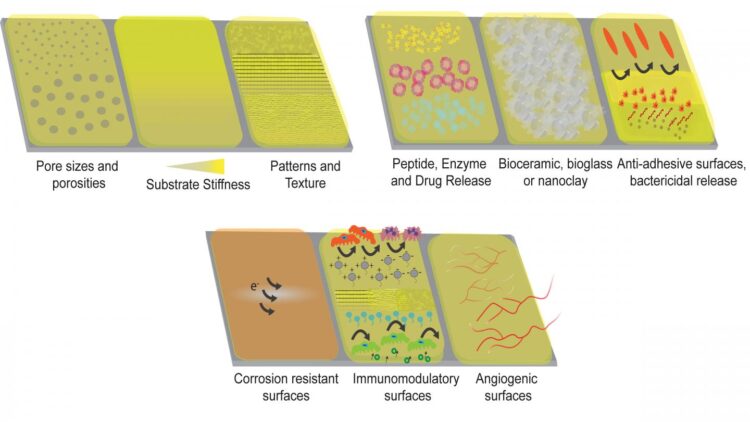

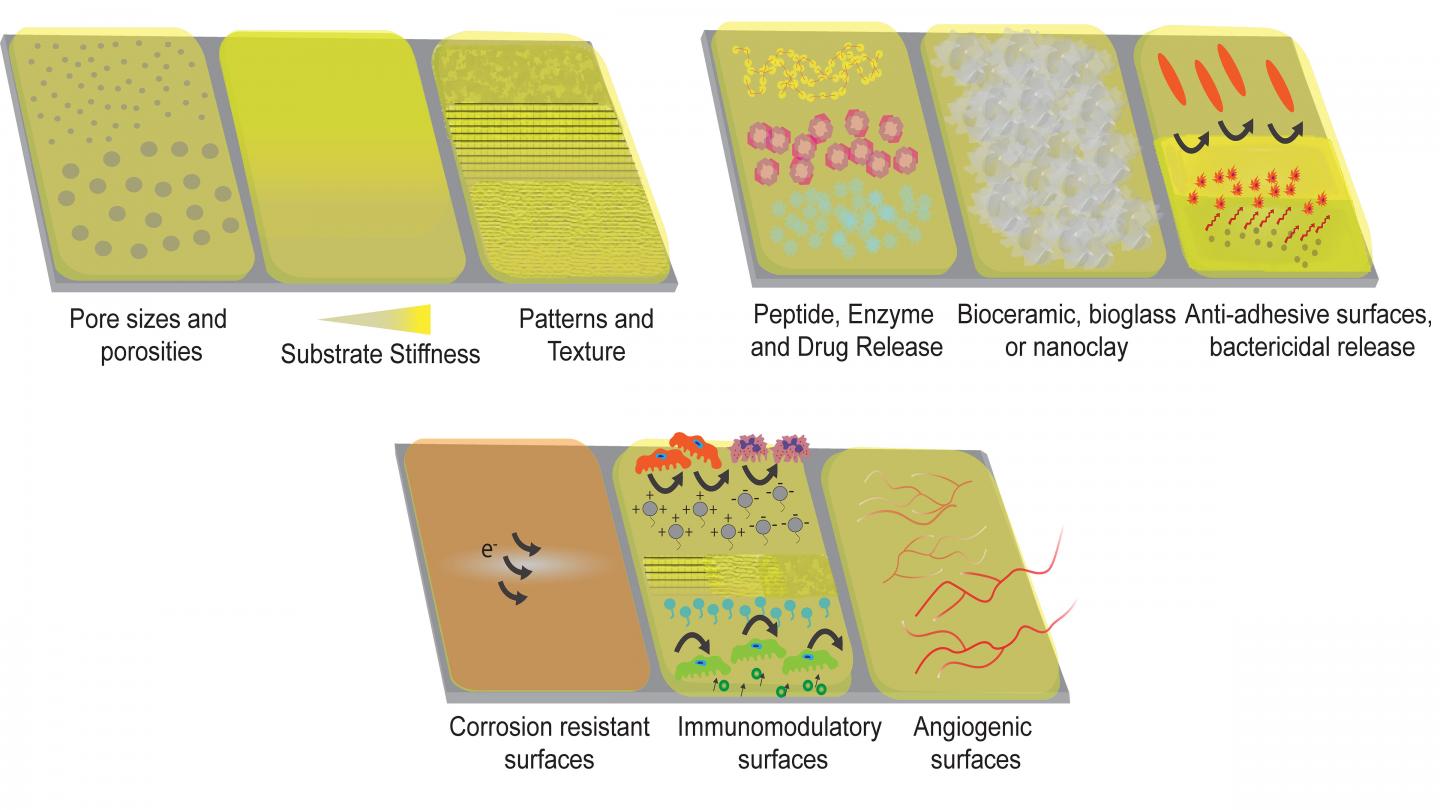

“One of the surprises is that the coatings can be modified in unlimited ways,” said Evis. “They can be composited, reconfigured, and tailored to allow or disallow certain biological activities, such as allowing cell attachment while disallowing bacterial attachment.”

Coatings may also be designed to possess multifunctionality, which is the goal in tissue engineering applications.

The researchers plan to improve biological functionality of natural polymer coatings on titanium implants. Even though natural polymers can be successfully coated on metal implants, the robustness, yield, and mechanical stability of polymers on metal are still very problematic.

They will try to surpass the need for complex devices and method to improve the stability of polymer-metal interactions and eventually achieve long-term interphase durability. The methods discussed could be used in tandem with other implant surface modification methods to further enhance bioactivity of the metallic implants.

###

The article “Multifunctional natural polymer-based metallic implant surface modifications” is authored by Ahmet Engin Pazarceviren, Ay?en Tezcaner, and Zafer Evis. The article will appear in Biointerphases on April 27, 2021 (DOI: 10.1116/6.0000876). After that date, it can be accessed at https:/

ABOUT THE JOURNAL

Biointerphases, an AVS journal published by AIP Publishing, emphasizes quantitative characterization of biomaterials and biological interfaces. As an interdisciplinary journal, a strong foundation of chemistry, physics, biology, engineering, theory, and/or modelling is incorporated into originated articles, reviews, and opinionated essays. See https:/

ABOUT AVS

AVS is an interdisciplinary, professional society with some 4,500 members worldwide. Founded in 1953, AVS hosts local and international meetings, publishes four journals, serves members through awards, training and career services programs and supports networking among academic, industrial, government, and consulting professionals. Its members come from across the fields of chemistry, physics, biology, mathematics, engineering and business and share a common interest in basic science, technology development and commercialization related to materials, interfaces, and processing.

Media Contact

Larry Frum

[email protected]

Related Journal Article

http://dx.