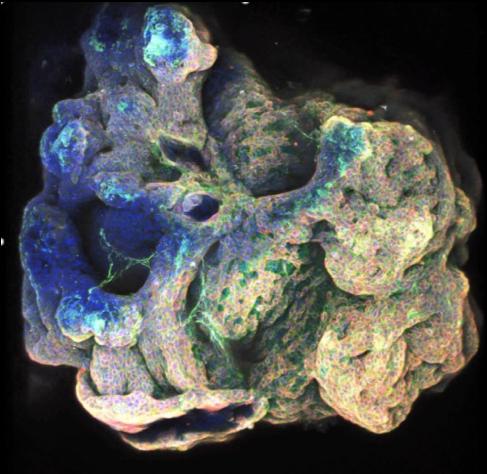

Credit: University of Cambridge

A team of engineers and scientists has developed a method of ‘multiplying’ organoids: miniature collections of cells that mimic the behaviour of various organs and are promising tools for the study of human biology and disease.

The researchers, from the University of Cambridge, used their method to culture and grow a ‘mini-airway’, the first time that a tube-shaped organoid has been developed without the need for any external support.

Using a mould made of a specialised polymer, the researchers were able to guide the size and shape of the mini-airway, grown from adult mouse stem cells, and then remove it from the mould when it reached the point where it could support itself.

Whereas the organoids currently used in medical research are at the microscopic scale, the method developed by the Cambridge team could make it possible to grow life-sized versions of organs. Their results are reported in the journal Advanced Science.

Organoids are tiny, three-dimensional cell assemblies that mimic the cell arrangement of fully-grown organs. They can be a useful way to study human biology and how it can go wrong in various diseases, and possibly how to develop personalised or regenerative treatments. However, assembling them into larger organ structures remains a challenge.

Other research teams have experimented with 3D printing techniques to develop larger mini-organs, but these often require an external support structure.

“Mini-organs are very small and highly fragile,” said Dr Yan Yan Shery Huang from Cambridge’s Department of Engineering, who co-led the research. “In order to scale them up, which would increase their usefulness in medical research, we need to find the right conditions to help the cells self-organise.”

Huang and her colleagues have proposed a new organoid engineering approach called Multi-Organoid Patterning and Fusion (MOrPF) to grow a miniature version of a mouse airway using stem cells. Using this technique, the scientists achieved faster assembly of organoids into airway tubes with uninterrupted passageways. The mini-airways grown using the MOrPF technique showed potential for scaling up to match living organ structures in size and shape, and retained their shape even in the absence of an external support.

The MOrPF technique involves several steps. First, a polymer mould – like a miniature version of a cake or jelly mould – is used to shape a cluster of many small organoids. The cluster is released from the mould after one day, and then grown for a further two weeks. The cluster becomes one single tubular structure, covered by an outer layer of airway cells. The moulding process is just long enough for the outer layer of the cells to form an envelope around the entire cluster. During the two weeks of further growth, the inner walls gradually disappear, leading to a hollow tubular structure.

“Gradual maturation of the cells is really important,” said Dr Joo-Hyeon Lee from Cambridge’s Wellcome – MRC Cambridge Stem Cell Institute, who co-led the research. “The cells need to be well-organised before we can release them so that the structures don’t collapse.”

The organoid cluster can be thought of like soap bubbles, initially packed together to form to the shape of the mould. In order to fuse into a single gigantic bubble from the cluster of compressed bubbles, the inner walls need to be broken down. In the MOrPF process, the fused organoid clusters are released from the mould to grow in floating, scaffold-free conditions, so that the cells forming the inner walls of the fused cluster can be taken out of the cluster. The mould can be made into different sizes or shapes, so that the researchers can pre-determine the shape of the finished mini-organ.

“The interesting thing is, if you think about the soap bubbles, the resulting big bubble is always spherical, but the special mechanical properties of the cell membrane of organoids make the resulting fused shape preserve the shape of the mould,” said co-author Professor Eugene Terentjev from Cambridge’s Cavendish Laboratory.

The team say their method closely approximated the natural process of organ tube formation in some animal species. They are hopeful that their technique will help create biomimetic organs to facilitate medical research.

The researchers first plan to use their method to build a three-dimensional ‘organ on a chip’, which enables real-time continuous monitoring of cells, and could be used to develop new treatments for disease while reducing the number of animals used in research. Eventually, the technique could also be used with stem cells taken from a patient, in order to develop personalised treatments in future.

###

The research was supported in part by the European Research Council, the Wellcome Trust and the Royal Society.

Media Contact

Sarah Collins

[email protected]

Related Journal Article

http://dx.