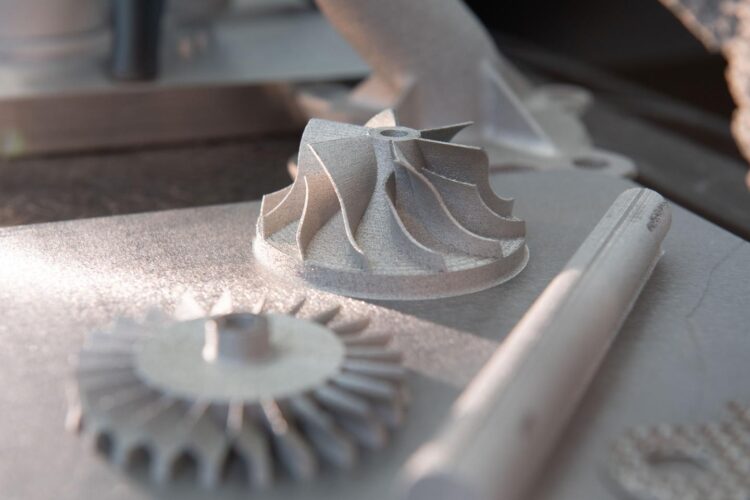

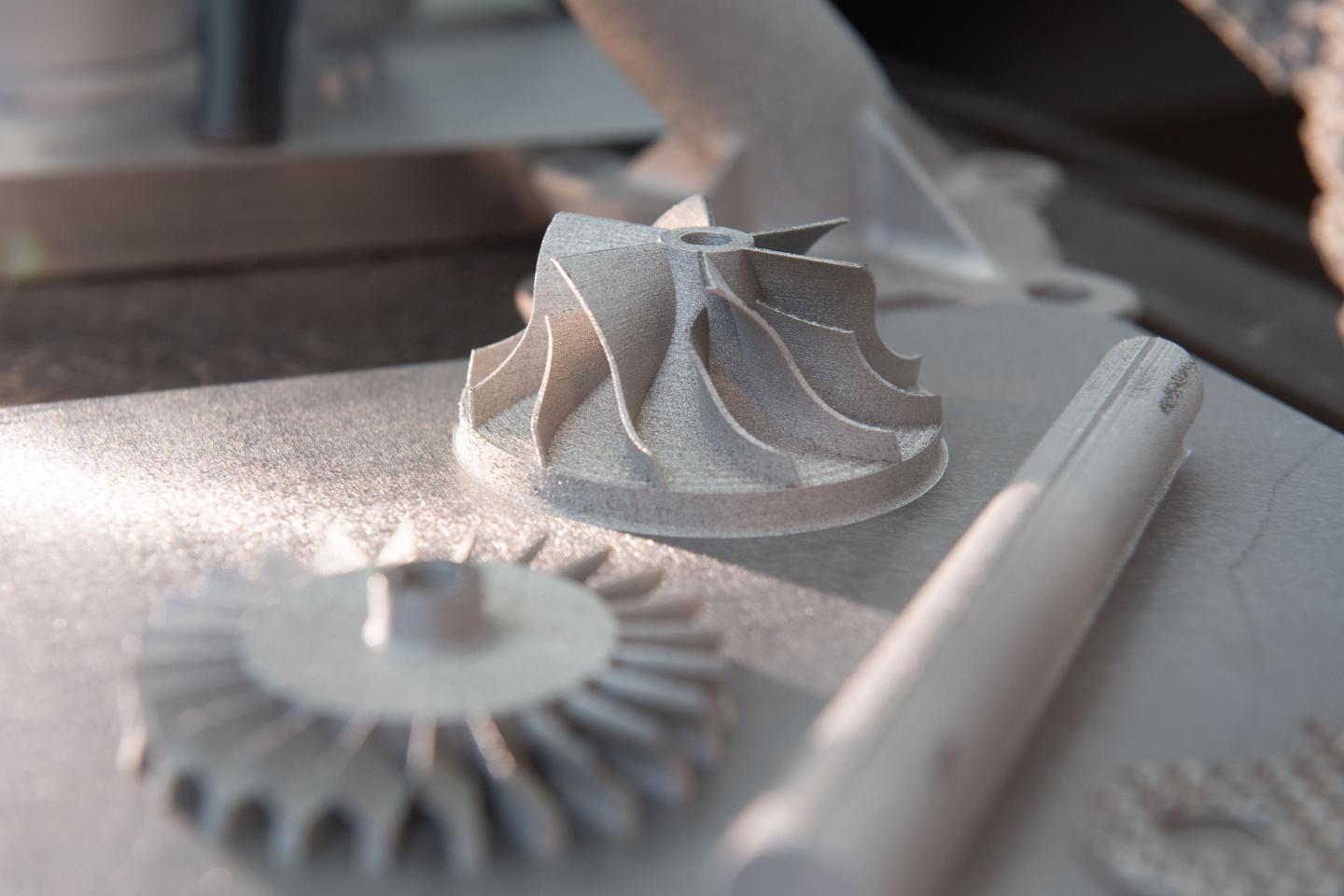

Credit: Dave McNally

ABERDEEN PROVING GROUND, Md. — Army researchers have discovered a way to monitor the performance of 3-D printed parts, which tend to have imperfections that affect performance in ways traditionally-machined parts do not.

A new study published recently in the International Journal of Advanced Manufacturing Technology showed that the Army could detect and monitor the wear and tear of 3-D printed maraging steel through sensor measurement. These types of measurements help Soldiers maintain readiness because these indicators help predict when parts will degrade or fail, and need replacement.

“3-D printed parts display certain attributes, due to the manufacturing process itself, which, unchecked, may cause these parts to degrade in manners not observed in traditionally-machined parts,” said Dr. Jaret C. Riddick, director of the Vehicle Technology Directorate at the U.S. Army’s Combat Capabilities Development Command’s Army Research Laboratory. “Because of this, it’s commonly understood that the use of these parts, in current cases, is meant to be a stop-gap to fill a critical need just as we have seen with 3-D printing during the COVID-19 response.”

He said the laboratory’s study points to scientific discovery that ensures readiness in increasingly contested environments where the immediate need for replacement parts places constraints on the time it takes to deliver them from far away. In these cases, Soldiers would opt for a stop-gap to continue the mission rather having to abort the mission.

This study was led by a team of researchers from the laboratory, the National Institute of Standards and Technology, CCDC Aviation and Missile Center and Johns Hopkins University, who likened cues from the material’s performance to a vehicle odometer reading that signals a need for an oil change.

“The strain or eddy current sensor would supply a measurement and let you know the part needs replaced,” said Dr. Todd C. Henry, a mechanical engineer at the laboratory who co-authored the study.

Henry wants to develop a tool for measuring the unique performance of each 3-D printed part acknowledging that each is different via sensor measurement.

“If I took a batch of paper clips and started bending them back and forth they’ll break from fatigue damage at different intervals depending on the internal imperfections associated with the steel,” Henry said. “Every real-world material and structure has imperfections that make it unique in terms of performance so if the batch of paper clips take 21-30 cycles to break, what we would do today is after 15 cycles throw the batch of paperclips away to be safe.”

He said the imperfections in 3-D printed parts are typically attributed to voids and geometric variance between the computer model and the print. Sensor technology he’s developing offers a way to track individual parts, predict failure points and replace them a few cycles before they break.

“In order to create a high trust situation, you take little risk such as throwing the paper clip away after 15 cycles even though the lowest lifetime in your test batch was 21. If you try and take more risk and put the throw away limit at 22 cycles then the paperclip may break on someone sometime but you will save money.”

The research team conducted an experimental validation set for assessing the real-time fatigue behavior of metallic additively manufactured maraging steel structures.

Army researchers are applying these findings to new studies to 3-D-printing of stainless steel parts and using machine-learning techniques, instead of sensors, to characterize the life of parts, Henry said.

“With 3-D printing, you might not be able to replace a part with the exact same material,” he said. “There is a cost and time benefit with 3-D printing that perhaps warrants using it anyway. Imagine a situation where you always chose the strongest material but there was another material that was cheaper and easier to get however you need to prove that this other material can be depended on.”

This study is as much about understanding the specific performance of a 3-D-printed material as it is about understanding our ability to monitor and detect performance and 3-D-printed material degradation, Henry said.

###

Henry’s co-authors for the paper, “In-Situ Fatigue Monitoring Investigation of Additively Manufactured Maraging Steel” are Dr. Francis Phillips and Dr. Dan Cole, CCDC Army Research Laboratory; Dr. Ed Garboczi, National Institute of Standards and Technology; Dr. Robert Haynes, Combat Capabilities Development Command Aviation and Missile Center and Dr. Terrence Johnson, Johns Hopkins University.

CCDC Army Research Laboratory is an element of the U.S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL discovers, innovates and transitions science and technology to ensure dominant strategic land power. Through collaboration across the command’s core technical competencies, CCDC leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more lethal to win the nation’s wars and come home safely. CCDC is a major subordinate command of the U.S. Army Futures Command.

Media Contact

T’Jae Ellis

[email protected]

Original Source

https:/

Related Journal Article

http://dx.