The University of the Basque Country-UPV/EHU is researching mortars and concrete manufactured from industrial by-products, within the circular economy approach

The consumption of raw materials has increased notably in industry in general, and in the construction industry in particular, amidst growing concerns over sustainability issues. Concrete and mortar are the most commonly used materials in construction, and many studies are currently under way to try and reduce the harmful effects of their manufacture. Concrete and mortar are made by mixing water, sand, cement and aggregates.

“The main problem is the amount of cement used to produce this type of material; cement manufacturing uses a huge amount of energy and natural resources, which implies a high level of CO2 emissions. Diverse studies are under way aimed at reducing the quantity of cement required. We are working to replace cement and aggregates (sand or gravel) with non-natural materials, in order to reduce the use of natural resources and optimise the mechanical and thermal properties of the materials produced,”explains Roque Borinaga Treviño, a researcher at the UPV/EHU’s Department of Mechanical Engineering.

To this end, the research team is analysing by-products from different industrial processes, which enable the mortars and concretes produced to be used for different functions, depending on the mechanical and thermal properties they acquire: ‘the aim is to reduce as much as possible the volume of industrial by-products that end up in landfill sites, and to reuse these products in accordance with the dictates of the circular economy,’ claims Dr Borinaga. Recently, the research team has explored three different by-products in three different areas.

Specific cases

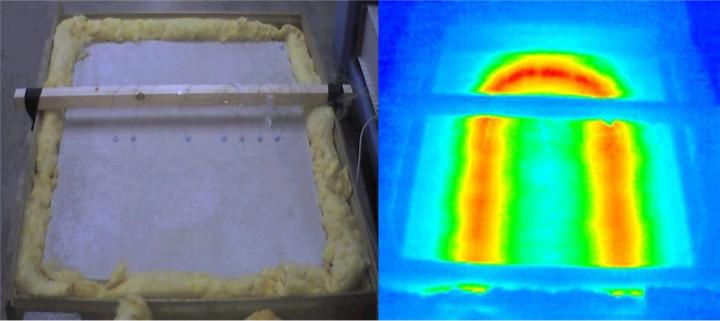

Firstly, they have studied the possibility of using industrial metal waste as a reinforcement in concrete or mortar, analysing mortars reinforced with brass fibres from electrical discharge machining. Secondly, and linked to this avenue of research aimed at reducing the amount of cement required, they have explored the use of lime mud waste from the paper industry, obtaining good results in terms of thermal conductivity and finding that the resulting material is adequate for use in radiant floor heating systems. And finally, they have used furnace slag as an aggregate: ‘the thermal conductivity of sand extracted from electric arc furnaces is low, making it a good option for insulation purposes,’ explains Dr Borinaga.

Although they are studying many different types of materials, what they are doing is basic research: ‘ours is the first step in researching these materials. Industrial by-products and waste are not particularly homogeneous, meaning that they vary greatly in accordance with their origin. Therefore, the first step is to analyse the properties bestowed by each specific type of waste. It is important to conduct these analyses with a large amount of waste with different origins, and to compare the results in order to determine whether or not the materials are suitable for use in manufacturing,’ he concludes.

###

Media Contact

Matxalen Sotillo

[email protected]

Original Source

https:/

Related Journal Article

http://dx.