Credit: Hoang Dinh and Patrick Suthers, Penn State

Microbes and other microscopic organisms could serve as sustainable “factories” to create many types of industrial materials because they naturally convert nutrients such as sugars into byproducts. However, creating industrial amounts of organic acids from renewable resources poses a challenge, because not many organisms can grow in highly acidic environments. With the help of gene editing and computational modeling tools, a team of researchers explored one type of yeast that could survive in the harsh environment created by acidic products.

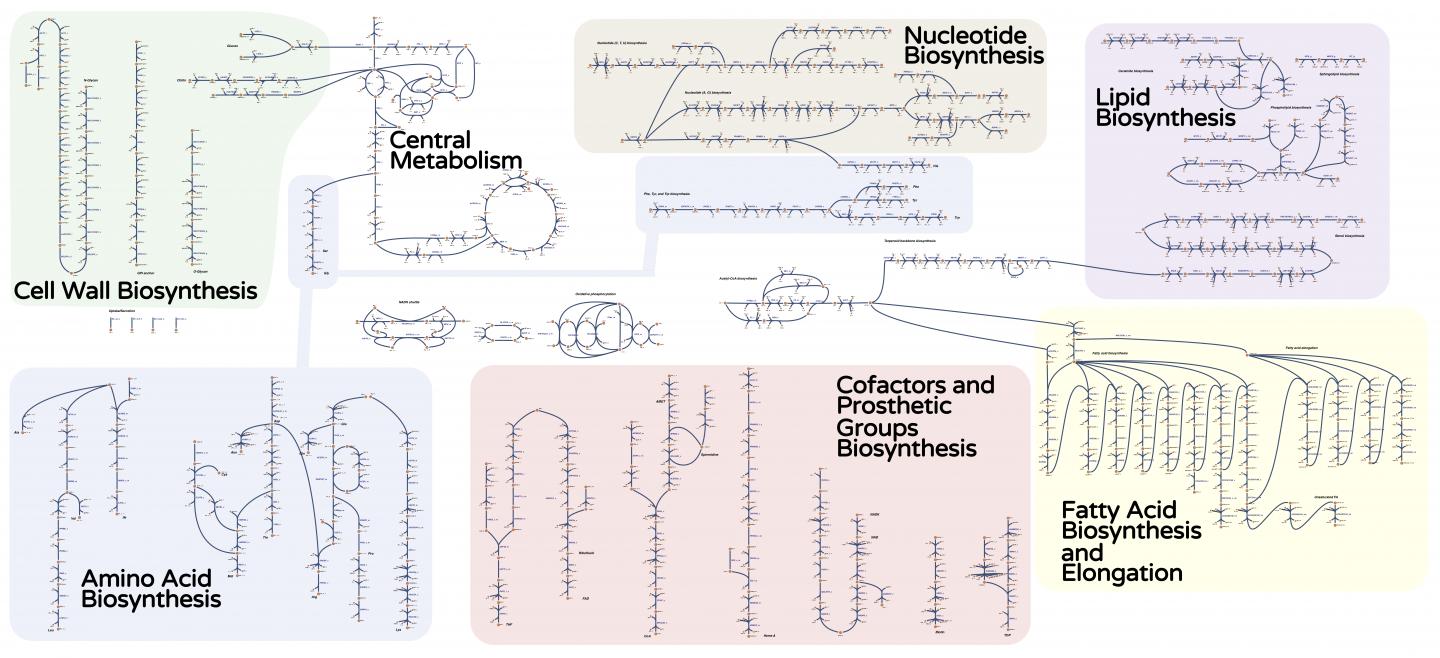

The team, which includes Penn State, the University of Illinois at Urbana-Champaign and Princeton University researchers, studied the yeast strain Issatchenkia orientalis, considered to be a “non-model” yeast because it has not been researched extensively. After reconstructing the yeast’s metabolism into a network model, the team examined its growth on different feedstock and subsequent byproducts. This strain was able to produce succinic acid, which is a precursor for industrial polymer production. The team reported its results in Metabolic Engineering Communications.

The researchers used a combination of genetic sequencing, gene editing, and sophisticated computational modeling to pinpoint which metabolic activities could be changed to maximize production of succinic acid without detriment to the yeast.

“The emergence of efficient CRISPR-Cas tools for making multiple genetic interventions in a single pass has emphasized the need for the development of predictive models and algorithms for suggesting which multiple genetic modifications to implement,” said Costas Maranas, the Donald B. Broughton Professor of chemical engineering and Institute for Computational and Data Sciences associate, Penn State, who co-led this study.

The computation-heavy approach, which ran on Penn State’s Roar supercomputer, was important in helping to refine the research direction, according to the researchers. The I. orientalis model covers 850 genes and contains 1,826 metabolic reactions, so identifying the right combination of genes and reactions to modify in order to produce succinic acid becomes a needle-in-a-haystack type of problem. Running thousands of computer simulations sifts through the hay and provides a much narrower set of experiments to test in a lab.

“With this approach, we can rank redesign hypotheses much faster than relying on a purely experimentalist approach,” said Patrick Suthers, postdoctoral scholar in chemical engineering, Penn State. “Our collaborators worked on developing genetic tools specifically for this organism, but even with their tools, it takes much longer to make modifications.”

The team’s analysis uses OptKnock, an optimization framework previously developed by the Maranas group, as part of the computational modeling.

Combining the computational techniques with traditional experiments not only informed the models with phenotypic measurements, but it also allowed the researchers to ensure their model was accurate in its predictions.

“One critical part of creating models is being able to say, yes, our predictions do make sense,” said Suthers. “In this case, our group focused on taking information from the genome in the organism, which our collaborators had sequenced. Then we take the genome and convert it into the functions that can take place in the cell.”

The result is a yeast model that can be used in any number of ways.

“Now that we have this comprehensive genome-scale model, we can look at things like the rates of organism growth and fluxes, and we can nail down key reactions in the metabolic system,” said Suthers. “We can also add in new genes to make new types of products.”

###

Collaborators on this research include Hoang Dinh and Siu Hung Joshua Chan, Penn State; Zia Fatma and Huimin Zhao, University of Illinois at Urbana-Champaign; and Yihui Shen and Joshua Rabinowitz, Princeton University.

The U.S. Department of Energy supported this work.

Media Contact

A’ndrea Elyse Messer

[email protected]

Related Journal Article

http://dx.