Construction of innovative accumulator ring as part of ALS-U project will keep Berkeley Lab at the forefront of synchrotron light source science

Credit: Matthaeus Leitner

An upgrade of the Advanced Light Source (ALS) at the U.S. Department of Energy’s (DOE’s) Lawrence Berkeley National Laboratory (Berkeley Lab) has passed an important milestone that will help to maintain the ALS’ world-leading capabilities.

On Dec. 23 the DOE granted approval for a key funding step that will allow the project to start construction on a new inner electron storage ring. Known as an accumulator ring, this inner ring will feed the upgraded facility’s main light-producing storage ring, and is a part of the upgrade project (ALS-U).

This latest approval, known as CD-3a, authorizes an important release of funds that will be used to purchase equipment and formally approves the start of construction on the accumulator ring. This approval is an essential step in a DOE “critical decision” process that involves in-depth reviews at several key project stages.

“It’s exciting to finally be able to start construction and see all our hard work come to fruition and to get one step closer to having a next-generation light source,” said David Robin, director of the ALS-U project.

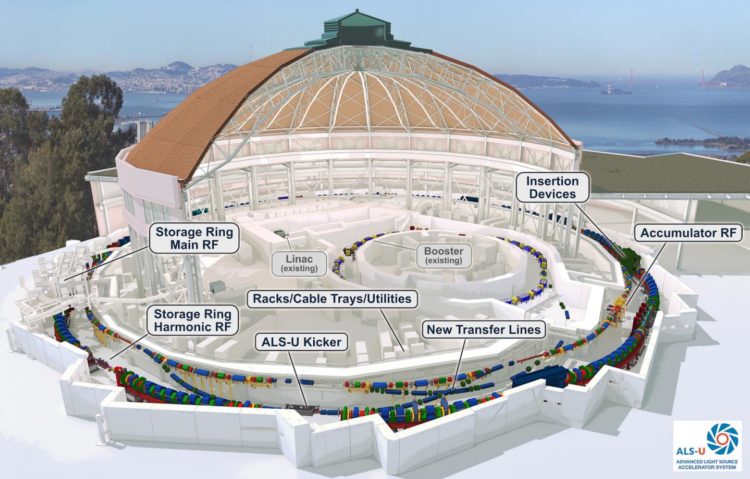

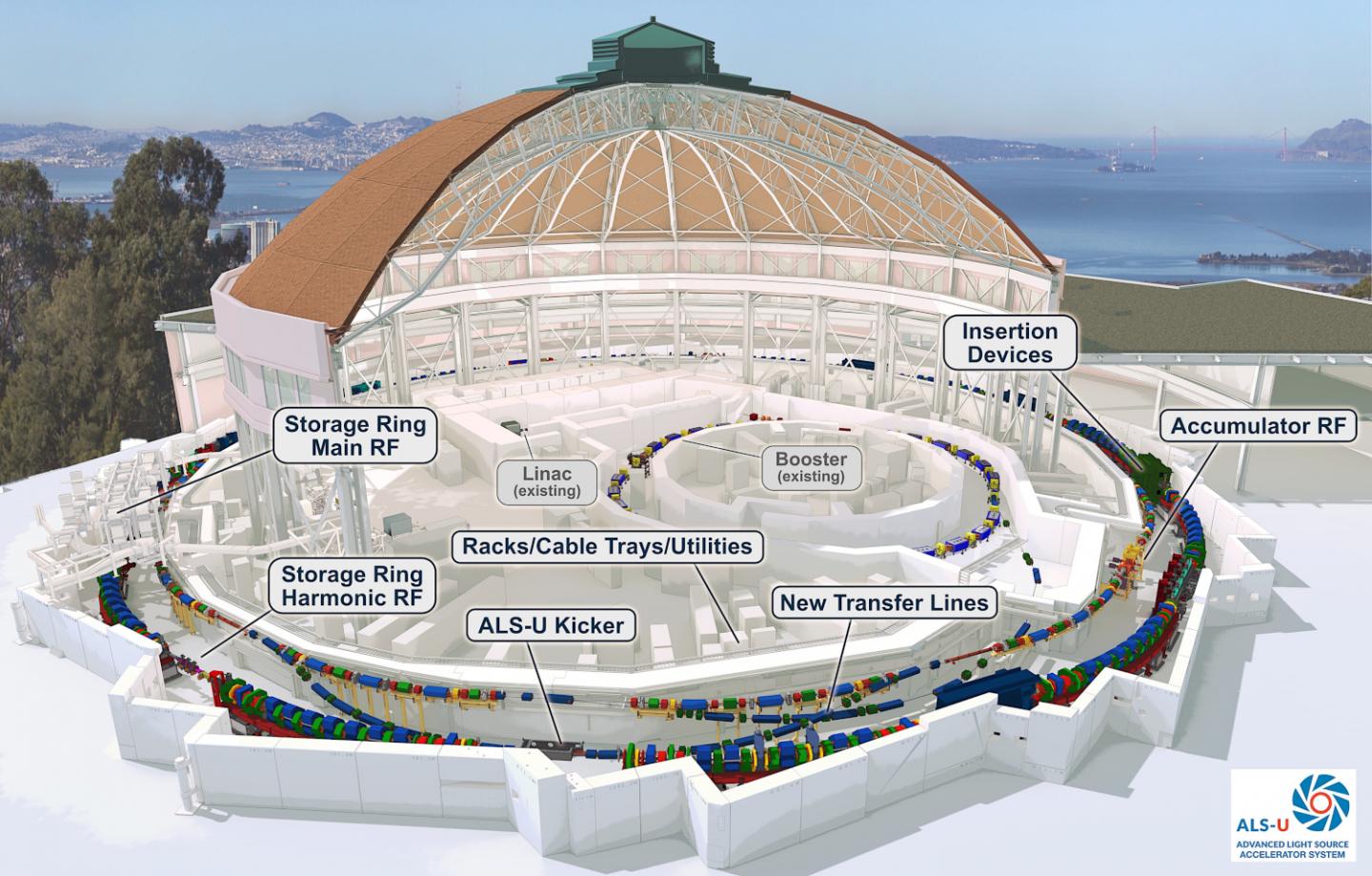

The ALS produces ultrabright light over a range of wavelengths, from infrared to high-energy X-rays, by accelerating electrons to nearly the speed of light and guiding them along a circular path.

Powerful arrays of magnets bend the beam of electrons, causing it to emit light that is channeled down dozens of beamlines for experiments in a wide range of scientific areas – from physics, medicine, and chemistry to biology and geology. More than 2,000 scientists from around the world conduct experiments at the facility each year.

Brighter, more laser-like beams, and ‘recycled’ electrons

In addition to installing the accumulator ring, the upgrade project will replace the existing main storage ring with a next-generation storage ring that will reduce the size of the light beams at their source from around 100 microns (millionths of a meter) to below 10 microns.

The combination of the accumulator ring and upgraded main storage ring will enable at least 100 times brighter beams at key energies, and will make the beams more laser-like by enhancing a property known as coherence. This will make it possible to reveal nanometer-scale features of samples, and to observe chemical processes and the function of materials in real time.

Today, electrons at the ALS are first accelerated by a linear (straight) accelerator and a booster ring before they are transferred to the storage ring that feeds light to the beamlines. After the upgrade, electrons from the booster ring will instead go to the accumulator ring, which will reduce the size and spread of the electron beam and accumulate multiple batches or “injections” of electron bunches from the booster ring before transferring bunches to the storage ring.

Shrinking the beam profile in the accumulator ring, together with an innovative technique for swapping electron bunches between ALS rings – and the use of improved magnetic devices called undulators that wiggle the electrons and help to narrow the path of the light they emit – will enable the higher brightness of the upgraded ALS.

The accumulator ring will also “recycle” incoming electron bunches – via a transfer line from the main storage ring – that have a depleted charge. It will restore them to a higher charge and feed them back into the storage ring.

This electron-bunch recycling, known as “bunch train swap-out,” is a unique design feature of the upgraded ALS that could also prove useful if adopted at other accelerator facilities around the globe. It will reduce the number of lost electrons, in turn reducing the workload for the facility’s production of electrons.

To allow precisely timed electron bunch-train exchanges between the accumulator ring and the booster and storage rings, three transfer lines are needed.

One of these transfer lines will deliver bunches of electrons from the booster ring to the accumulator ring, where the size of the bunches will be reduced and the charge progressively increased, before delivering them via another transfer line to the main storage ring. A third transfer line will allow excess electrons that would otherwise be discarded to reenter the accumulator ring for reuse.

“Every upgrade project should contribute to accelerator technology and push the field forward in some way,” Robin said. “Recent state-of-the art facilities and upgrades in Europe and the U.S. have implemented technology that we are making use of. Using an accumulator with bunch train swap-out injection is one of our main contributions.”

At the leading edge of ‘soft’ and ‘tender’ X-ray science

Robin credited Christoph Steier, who is the Accelerator Systems Lead for the ALS-U project, and his team for developing the bunch train swap-out technique and related technologies that are critical for the facility’s enhanced performance.

The ALS-U project will keep the facility at the forefront of research using “soft” X-rays, which are well-suited to studies of the chemical, electronic, and magnetic properties of materials. Soft X-rays can be used in studies involving lighter elements like carbon, oxygen, and nitrogen, and have a lower energy than “hard” X-rays that can penetrate deeper into samples.

It will also expand access to “tender” X-rays, which occupy an energy range between hard and soft X-rays and can be useful for studies of earth, environmental, energy, and condensed-matter sciences.

But achieving this performance is a tricky feat, noted Daniela Leitner, who is responsible for accelerator removal and installation for the ALS-U project. The main storage ring is housed in thick concrete tunnels designed to fit one ring, and now the upgrade requires that a second ring be squeezed in.

Accumulator ring to function as a mini ALS, will boost performance of new storage ring

“We need to build a ‘mini ALS,'” Leitner said, in the form of the accumulator ring. The accumulator ring will measure about 600 feet in circumference while the main storage ring will be about 640 feet in circumference. It must be installed about 6 1/2 feet above the floor, just 7 inches below the ceiling height in some places – and fit snugly around an inner wall to allow workers to safely navigate the ALS’ tunnels.

Robin noted, “This is a complicated logistical ‘dance.’ It is a very confined space, and there is equipment in the existing tunnel that has to be moved to make room.”

The accumulator ring is designed to be compact, with a reduced weight, footprint, and power consumption compared to the existing storage ring.

The accumulator ring installation – which is enabled by the CD-3a release of funds – will also be carefully orchestrated to minimize disruptions to ALS operations, with installation work fit into regularly scheduled downtimes over the next few years. The ALS typically runs 24/7 outside of scheduled maintenance downtimes.

The plan is to install and test the accumulator ring prior to a planned yearlong shutdown – with the potential to test the new ring even during regular ALS operations. The shutdown period, known as “dark time,” will allow the removal of the existing storage ring and installation of the new storage ring.

Installing the accumulator ring in advance allows the project team to minimize the shutdown period, which will require the removal and replacement of 400 tons of equipment. This final stage of the project is slated to begin in a few years.

The accumulator ring will bring about 80 tons of new equipment into the facility, with construction expected to begin in the summer of 2020. There are dozens of major pieces of equipment to install, including specialized magnetic devices that help to bend and focus the electron beam. These magnetic devices are part of an array of seven pieces that must be installed in each of the 12 ALS sectors and connected by vacuum tubes.

The accumulator ring installation will take an estimated 53,000 worker-hours and requires the placement of thousands of cables.

Prototypes and simulations to ease assembly, installation, troubleshooting

The ALS-U project team has built and acquired prototypes for key components of the accumulator ring, and has constructed models of some of the accumulator ring equipment at their designed height to find the best installation methods. Project crews will also build out fully equipped sections of the accumulator ring to measure their alignment and test the integrated hardware prior to installation to help speed up the process.

Leitner said that about 80 percent of the installation can be assisted by an overhead crane that will lift heavy equipment into the tunnels, but there are also plans for elevated platforms to ease the installation, and customized lifts to enable installation where the crane cannot be used.

Steier said that technical improvements in accelerator simulations should help to troubleshoot and negate potential problems ahead of time that may arise with the commissioning of the accumulator ring and storage ring. The algorithms account for misaligned magnets and power-supply fluctuations, for example, that are common with constructing large accelerator facilities.

“In general, we simulate everything beforehand, and over time these simulations have become more accurate,” he said, to the point that the simulations can actually guide design choices for the accelerator equipment, and could speed up the ALS-U startup process.

Robin said, “I’m really proud of what the team has accomplished over the last few years.”

###

The Advanced Light Source is a DOE Office of Science User Facility.

More:

* Overview: The Advanced Light Source Upgrade (ALS-U) project

* Toward a New Light: Advanced Light Source Upgrade Project Moves Forward

Founded in 1931 on the belief that the biggest scientific challenges are best addressed by teams, Lawrence Berkeley National Laboratory and its scientists have been recognized with 13 Nobel Prizes. Today, Berkeley Lab researchers develop sustainable energy and environmental solutions, create useful new materials, advance the frontiers of computing, and probe the mysteries of life, matter, and the universe. Scientists from around the world rely on the Lab’s facilities for their own discovery science. Berkeley Lab is a multiprogram national laboratory, managed by the University of California for the U.S. Department of Energy’s Office of Science.

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit https:/

Media Contact

Glenn Roberts Jr.

[email protected]

510-486-5582

Original Source

https:/