Towards a green and sustainable society

Credit: Kobe University

The ecological bio-production of xylitol and cellulose nanofibers using modified yeast cells, from material produced by the paper industry has been achieved by a Japanese research team. This discovery could contribute to the development of a greener and more sustainable society. The findings were published on March 4, in Green Chemistry.

The research was carried out by a group led by Assistant Professor Gregory Guirimand-Tanaka, Professor Tomohisa Hasunuma and Professor Akihiko Kondo from the Graduate School of Science, Technology and Innovation and the Engineering Biology Research Center of Kobe University.

In his effort to develop innovative processes to achieve a sustainable society, Professor Kondo has focused on a variety of bio-compounds such as xylitol, a highly valuable commodity chemical, which is widely used in both the food and pharmaceutical industries (for example, as a sugar substitute in chewing gum).

Professor Kondo’s group is also interested in innovative nanomaterials such as cellulose nanofibers, which present huge economic potential due to the properties of nanocellulose (mechanical properties, film-forming properties, viscosity etc.), and significant applications in food, hygiene, absorbent, medical, cosmetic and pharmaceutical products.

The worldwide demand for both xylitol and cellulose nanofibers is constantly growing, and the cost and environmental impact of their industrial production remain very high.

The industrial production of xylitol and cellulose nanofibers from purified D-xylose and cellulose fibers respectively involve costly and polluting processes. In order to solve these issues and realize a sustainable and environmentally-conscious society, we must make use of renewable biomass such as paper paste (Kraft pulp) and develop innovative processes.

Biotechnological production of xylitol and cellulose nanofibers using Kraft pulp, deriving from the paper industry, could be an advantageous option, as this material is abundant, contains reasonable amounts (17%) of D-xylose, and can be converted into highly valuable commodity compounds and nanomaterials.

To release the D-xylose contained in Kraft pulp, we usually need to add a large amount of commercial enzymes (CE), which are very costly. Therefore, we decided to use microorganisms such as modified yeast, which is capable of producing these enzymes by itself, in order to reduce the amount of CE initially required. The modified yeast cells developed are carrying these enzymes directly on their own cell surface, and we call this strategy “cell surface display” technology.

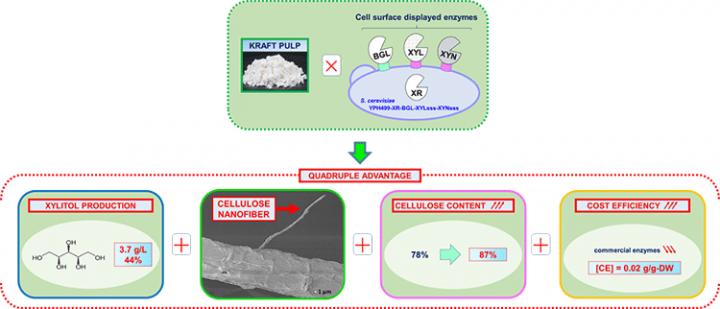

In this study, xylitol and cellulose nanofibers were co-produced from Kraft pulp by using a modified strain of baker’s yeast (Saccharomyces cerevisiae YPH499 strain) expressing three different enzymes (β-D-glucosidase (BGL), xylosidase (XYL) and xylanase (XYN)) co-displayed on the cell surface.

By using this strategy, we were not only able to produce xylitol and cellulose nanofibers, but also to considerably increase the purity of the cellulose itself and the cost efficiency of the process by reducing the amount of CE initially required (figure 1).

Last but not least, our team was able to successfully perform these experiments in larger volumes by using 2-liter jar fermenters, enabling us to further scale up bio-refinery industrial production of xylitol and cellulose nanofibers from Kraft pulp (figure 2).

Based on these findings, the team will continue to look for ways to increase the sustainable bio-production of xylitol and cellulose nanofibers through genetic engineering of yeast cells.

###

Media Contact

Eleanor Wyllie

[email protected]

Original Source

http://www.

Related Journal Article

http://dx.