Credit: ICFO

Invented approximately 50 years ago, surgical medical meshes have become key elements in the recovery procedures of damaged-tissue surgeries, the most common being hernia repair. When implanted within the tissue of the patient, the flexible and conformable design of these meshes helps hold muscles tight and allows patients to recover much faster than through the conventional surgery of sewing and stitching.

However, the insertion of a medical implant in a patient’s body carries alongside the risk of bacterial contamination during surgery and subsequent formation of an infectious biofilm over the surface of the surgical mesh. Such biofilms tend to act like a plastic coating, impeding any sort of antibiotic agent to reach and attack the bacteria formed on the film in order to stop the infection. Thus, antibiotic therapies, which are time-limited, could fail against these super resistant bacteria and the patient could end up in recurring or never-ending surgeries that could even lead to death. As a matter of fact, according to the European Antimicrobial Resistance Surveillance Network (EARS-Net), in 2015 more than 30,000 deaths in Europe were linked to infections with antibiotic-resistant bacteria.

In the past, several approaches have been sought to prevent implant contamination during surgery. Post-surgery aseptic protocols have been established and implemented to fight these antibiotic-resistant bacteria but none have entirely fulfilled the role of solving this issue.

In a recent study published in Nano Letters and highlighted in Nature Photonics, ICFO researchers Dr. Ignacio de Miguel, Arantxa Albornoz, led by ICREA Prof. at ICFO Romain Quidant, in collaboration with researchers Irene Prieto, Dr. Vanesa Sanz, Dr. Christine Weis and Dr. Pau Turon from the major medical device and pharmaceutical device company B. Braun, have devised a novel technique that uses nanotechnology and photonics to dramatically improve the performance of medical meshes for surgical implants.

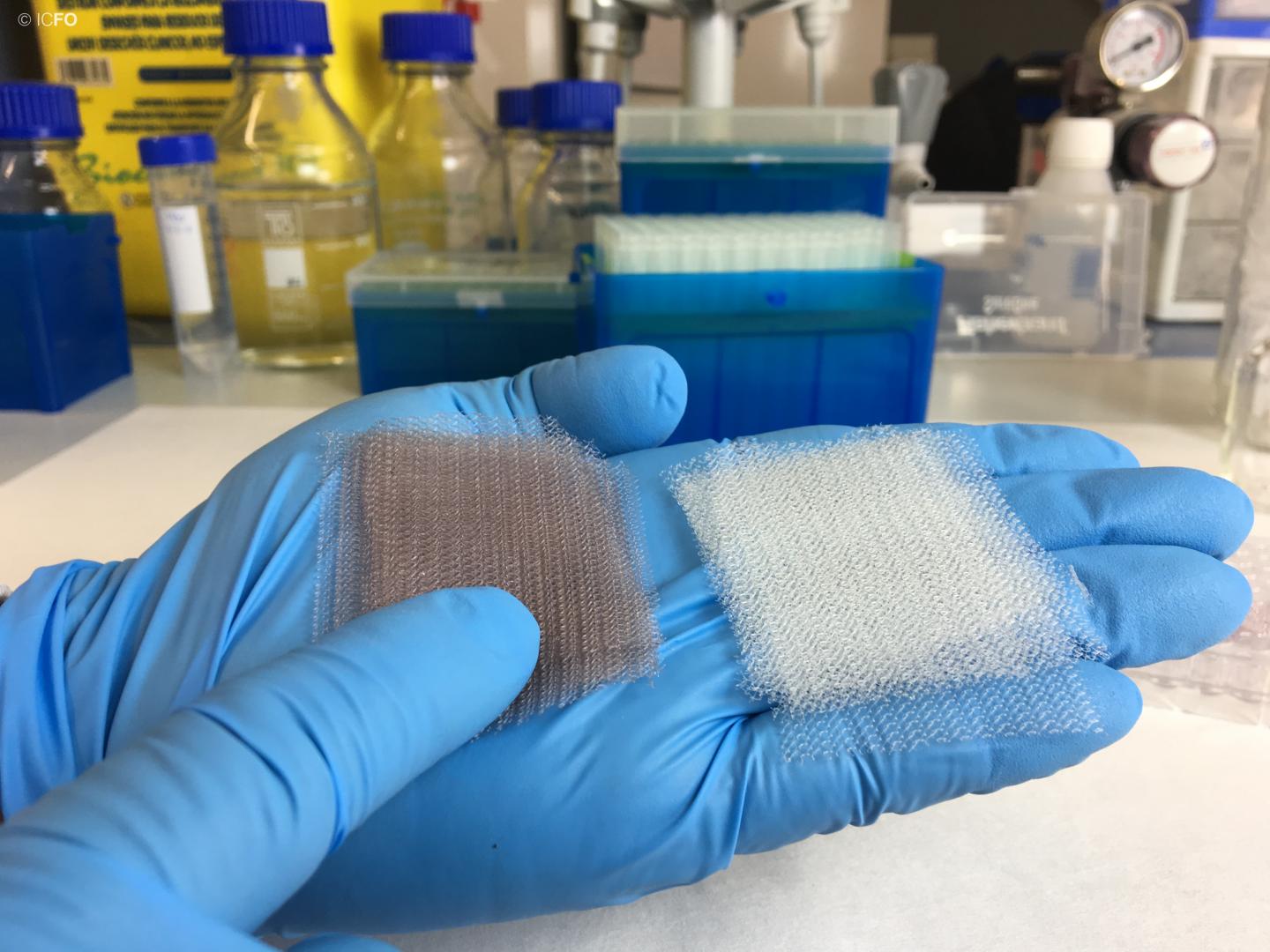

Through an ongoing collaboration since 2012, the team of researchers at ICFO and B. Braun Surgical, S.A., developed a medical mesh with a particular feature: the surface of the mesh was chemically modified to anchor millions of gold nanoparticles. Why? Because gold nanoparticles have been proven to very efficiently convert light into heat at very localized regions.

The technique of using gold nanoparticles in light-heat conversion processes had already been tested in cancer treatments in previous studies. Even more, at ICFO this technique had been implemented in several previous studies supported by the Cellex Foundation, thus being another salient example of how early visionary philanthropic support addressed at tackling fundamental problems eventually leads to important practical applications. For this particular case, in knowing that more than 20 million hernia repair operations take place every year around the world, they believed this method could reduce the medical costs in recurrent operations while eliminating the expensive and ineffective antibiotic treatments that are currently being employed to tackle this problem.

Thus, in their in-vitro experiment and through a thorough process, the team coated the surgical mesh with millions of gold nanoparticles, uniformly spreading them over the entire structure. They tested the meshes to ensure the long-term stability of the particles, the non-degradation of the material, and the non-detachment or release of nanoparticles into the surrounding environment (flask). They were able to observe a homogenous distribution of the nanoparticles over the structure using a scanning electron microscope.

Once the modified mesh was ready, the team exposed it to S. aureus bacteria for 24 hours until they observed the formation of a biofilm on the surface. Subsequently, they began exposing the mesh to short intense pulses of near infrared light (800 nm) during 30 seconds to ensure thermal equilibrium was reached, before repeating this treatment 20 times with 4 seconds of rest intervals between each pulse. They discovered the following: Firstly, they saw that illuminating the mesh at the specific frequency would induce localized surface plasmon resonances in the nanoparticles–a mode that results in the efficient conversion of light into heat, burning the bacteria at the surface. Secondly, by using a fluorescence confocal microscope, they saw how much of the bacteria had died or was still alive. For the bacteria that remained alive, they observed that the biofilm bacteria became planktonic cells, recovering their sensitivity or weakness towards antibiotic therapy and to immune system response. For the dead bacteria, they observed that upon increasing the amount of light delivered to the surface of the mesh, the bacteria would lose their adherence and peel off the surface. Thirdly, they confirmed that operating at near infrared light ranges was completely compatible with in-vivo settings, meaning that such a technique would most probably not damage the surrounding healthy tissue. Finally, they repeated the treatment and confirmed that the recurrent heating of the mesh had not affected its conversion efficiency capabilities.

As ICREA Prof at ICFO Romain Quidant comments, “the results of this study have paved the way towards using plasmon nanotechnologies to prevent the formation of bacterial biofilm at the surface of surgical implants. There are still several issues that need to be addressed but it is important to emphasize that such a technique will indeed signify a radical change in operation procedures and further patient post recovery.”

As Director of Research and Development of B. Braun Surgical, S.A. Dr. Pau Turon explains, “our commitment to help healthcare professionals to avoid hospital related infections pushes us to develop new strategies to fight bacteria and biofilms. Additionally, the research team is exploring to extend such technology to other sectors where biofilms must be avoided.”

###

Reference: Plasmon-based biofilm inhibition on surgical implants, Ignacio de Miguel, Irene Prieto, Arantxa Albornoz, Vanesa Sanz, Christine Weis, Pau Turón, Romain Quidant, Nano Letters, 2019, 10.1021/acs.nanolett.9b00187

ABOUT ICFO

ICFO – The Institute of Photonic Sciences was founded in 2002 by the Government of Catalonia and the Universitat Politècnica de Catalunya (UPC), both of which are members of its board of trustees along with the Cellex and Mir-Puig Foundations, philanthropic entities that have played a critical role in the advancement of the institute since 2007. Located in the Mediterranean Technology Park in the metropolitan area of Barcelona, the institute currently hosts 400 people, organized in 26 research groups in 60 state-of-the-art research laboratories. Research lines encompass diverse areas in which photonics plays a decisive role, with an emphasis on basic and applied themes relevant to medicine and biology, advanced imaging techniques, information technologies, a range of environmental sensors, tunable and ultra-fast lasers, quantum science, photovoltaics and the properties and applications of nano-materials such as graphene, among others. In addition to two state awarded Severo Ochoa accreditations of excellence, ICFOnians have been awarded 15 ICREA Professorships and 35 European Research Council grants. ICFO participates actively in the European Technological Platform Photonics21 and is also very proactive in fostering entrepreneurial activities, spin-off creation, and creating collaborations and links between industry and ICFO researchers. To date, ICFO has helped create 7 start-up companies.

ABOUT B. BRAUN

With more than 63,000 employees in 64 countries, the B. Braun family business ranks among the leading providers of solutions for the healthcare market worldwide and supplies users and patients with products and product systems for anaesthesia, intensive medicine, cardiology, extracorporeal blood treatment, surgery, or the homecare sector, as well as with services for clinics and practicing doctors. In a constructive dialog with customers and partners, B. Braun promotes efficient solutions that preserve people’s health and sustainably improve their lives.

B. Braun Surgical is a subsidiary of the B. Braun Group that belongs to the Aesculap division. The division’s business is divided into seven core indications: general open surgery, orthopaedic joint replacement, neurosurgery, laparoscopic surgery, interventional vascular diagnostics & therapy, degenerative spinal disorders and cardiothoracic surgery. Since 1995 the plant based in Rubí has been a Centre of Excellence for surgical sutures. In 2008, Rubí was given greater responsibility and was appointed Center of Excellence for the Closure Technologies strategic business unit of the Aesculap Division. B. Braun Spain is the reference center of the B. Braun Group and as such is globally responsible for Research and Development, Manufacturing, Quality Management, Regulatory Affairs, Strategical Marketing and Supply Chain Management.

Furthermore, Research & Development department of B. Braun Surgical cooperates with medical and scientific institutions and offers them the accumulated knowledge and experience of B. Braun in order to contribute to medical progress. Some of the main hospitals in Catalonia are into a partnership agreement with B. Braun in order to investigate surgical techniques to improve and innovate in closure technologies, tissue strength and local haemostatics.

Moreover, B. Braun Surgical collaborates closely with top research institutions such as ICFO – The Institute of Photonic Sciences, Universitat Politècnica de Catalunya, Universitat Autònoma de Barcelona, Max Planck Institute for Polymer Research, Leitat, Eurecat and Catalan Health Institute, among others.

Media Contact

Alina Hirschmann

[email protected]

Related Journal Article

http://dx.