Credit: NYU Tandon School of Engineering

RESEARCH TRIANGLE PARK, N.C. — An Army-funded landmark discovery at New York University could change the way researchers develop and use optical technologies, such as lasers, sensors and photonic circuits over the next decade.

After years of research, the team of scientists achieved what many thought was perhaps impossible-they developed a method to create colloids that crystallize into the diamond lattice. This photonic technique, published in Nature, could lead to cheap, reliable and scalable fabrication of 3D photonic crystals for optical circuits and light filters.

These 3D photonic crystals–self-assembled formations of miniscule materials in a stable assembly–could open the door to lightweight high-efficiency lasers, precise light control with 3D photonic circuits and new materials for managing thermal or radio signatures.

High-efficiency lasers are key to Army modernization priorities, including Air and Missile Defense, as they play a key role in both precision sensing and directed energy systems. Likewise, efficient lasers and integrated photonic circuits will play a key role in next-generation technologies like light-based quantum computing, atomic clocks and gyroscopes for precision navigation and timing, and optical systems with improved size, weight, and power.

“This long-sought demonstration of the first self-assembled colloidal diamond lattices will unlock new research and development opportunities for important Department of Defense technologies which could benefit from 3D photonic crystals,” said Dr. Evan Runnerstrom, program manager, Army Research Office, an element of the U.S. Army Combat Capabilities Development Command’s Army Research Laboratory.

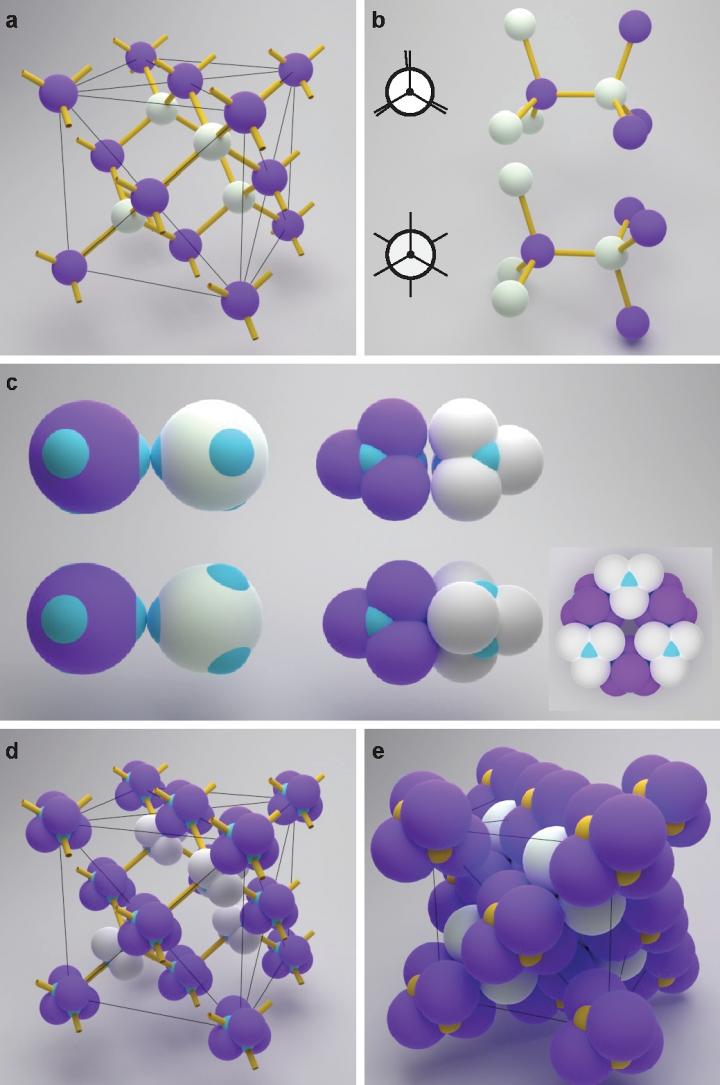

Colloidal crystals, made up of spheres hundreds of times smaller than the diameter of a human hair, can be arranged in different crystalline shapes depending on how the spheres are linked to one another. Each colloid attaches to another using strands of DNA glued to surfaces of the colloids that function as a kind of molecular Velcro. When colloids collide with each other in a liquid bath, the DNA snags and the colloids are linked. Depending on where the DNA is attached to the colloid, they can be programmed to spontaneously create complex structures.

This process has been used in the past to create strings of colloids and even close-packed cubic colloidal crystals, but not the diamond structure–which displays an optical band gap for visible light. Much as a semiconductor filters out electrons in a circuit, an optical band gap completely rejects certain wavelengths of light. Filtering light in this way is practical only if the colloids are arranged in a diamond formation, a process previously deemed too difficult and expensive to perform at commercial scale.

“There’s been a great desire among engineers to make a diamond structure,” said Dr. David Pine, professor of chemical and biomolecular engineering at the NYU Tandon School of Engineering. “Most researchers had given up on it, to tell you the truth – we may be the only group in the world who is still working on this. I think the publication of the paper will come as something of a surprise to the community.”

The investigators discovered that they could use a steric interlock mechanism that would spontaneously produce the necessary staggered bonds to make this structure possible. When these pyramidal colloids approached each other, they linked in the necessary orientation to generate a diamond formation. Rather than going through the painstaking and expensive process of building these structures through the use of top-down approaches like nanofabrication, this mechanism allows the colloids to structure themselves from the bottom-up without the need for outside interference. Furthermore, the diamond structures are stable, even when the liquid they form in is removed.

The team and their collaborators–including researchers from the Centre de Recherche Paul Pascal – CNRS, Pessac, France; and Sungkyunkwan University, Suwon, South Korea–are now focused on converting these colloidal diamonds into 3D photonic crystals that can be used in a practical setting. They are already creating materials using their new structures that can filter out optical wavelengths in order to prove their usefulness in future technologies.

“I am thrilled with this result because it wonderfully illustrates a central goal of ARO’s materials design program — to support high-risk, high-reward research that unlocks bottom-up routes to creating extraordinary materials that were previously impossible to make,” Runnerstrom said.

###

The National Science Foundation also funded this research.

Visit the laboratory’s Media Center to discover more Army science and technology stories

CCDC Army Research Laboratory is an element of the U.S. Army Combat Capabilities Development Command. As the Army’s corporate research laboratory, ARL discovers, innovates and transitions science and technology to ensure dominant strategic land power. Through collaboration across the command’s core technical competencies, CCDC leads in the discovery, development and delivery of the technology-based capabilities required to make Soldiers more lethal to win the nation’s wars and come home safely. CCDC is a major subordinate command of the U.S. Army Futures Command.

Media Contact

Lisa B Bistreich-Wolfe

[email protected]

Original Source

https:/

Related Journal Article

http://dx.