Why do carbon nanotubes line up? They’re in a groove

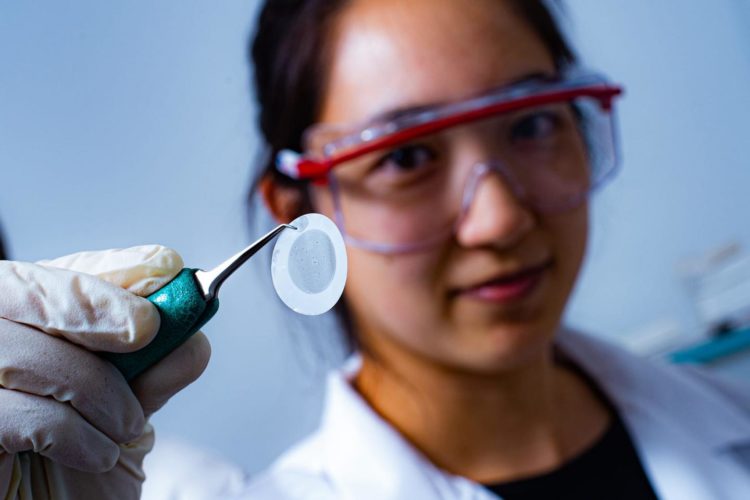

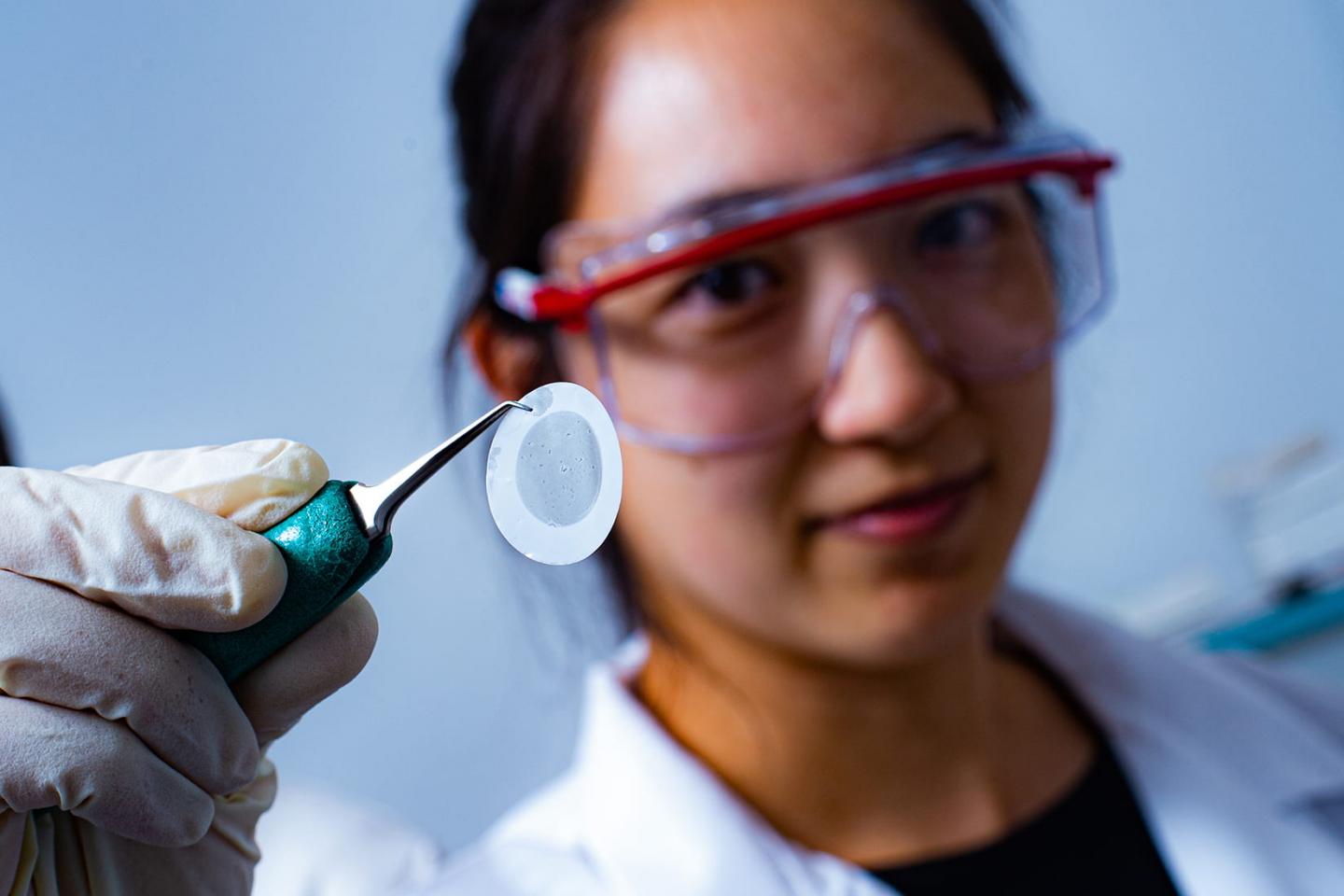

Credit: Jeff Fitlow/Rice University

HOUSTON — (March 9, 2020) — Ultrathin carbon nanotubes crystals could have wonderous uses, like converting waste heat into electricity with near-perfect efficiency, and Rice University engineers have taken a big step toward that goal.

The latest step continues a story that began in 2013, when Rice’s Junichiro Kono and his students discovered a breakthrough method for making carbon nanotubes line up in thin films on a filter membrane.

Nanotubes are long, hollow and notoriously tangle-prone. Imagine a garden hose that’s dozens of miles long, then shrink the diameter of the hose to the width of a few atoms.

Anyone who’s ever fought with a knotted hose can appreciate Kono’s feat: He and his students had turned a mob of unruly nanotubes into a well-ordered collective. Of their own accord, and by the billions, nanotubes were willingly lying down side by side, like dry spaghetti in a box.

The problem? Kono and his students had no idea why it was happening.

“It was magical. I mean, really mysterious,” said Kono, an electrical engineer, applied physicist and materials scientist who has studied carbon nanotubes for more than two decades. “We had no idea what was really happening on a microscopic scale. And most importantly, we did not even know in which direction that nanotubes would align.”

He and his team published their findings in 2016, and the field weighed in with possible explanations. The answer, as described in a new paper by Kono’s team and collaborators in Japan, is both unexpected and simple: Tiny parallel grooves in the filter paper — an artifact of the paper’s production process — cause the nanotube alignment. The research is available online in the American Chemical Society journal Nano Letters.

Kono said a graduate student in his lab, study lead author Natsumi Komatsu, was the first to notice the grooves and associate them with nanotube alignment.

“I found that any commercially purchased filter membrane paper used for this technique has these grooves,” Komatsu said. “The density of grooves varies from batch to batch. But there are always grooves.”

To form the 2D crystalline films, researchers first suspend a mixture of nanotubes in a water-surfactant solution. The soaplike surfactant coats the nanotubes and acts as a detangler. In 2013, Kono’s students were using vacuum filtration to draw these mixtures through membrane filter paper. The liquid passed through the paper membrane, leaving a film of aligned nanotubes on top.

In an exhaustive set of experiments, Komatsu and colleagues, including Kono group postdoctoral researcher Saunab Ghosh, showed that the alignment of nanotubes in these films corresponded to parallel, submicroscopic grooves on the paper. The grooves likely form when the filter paper is pulled onto rolls at the factory, Kono said.

Komatsu examined dozens of samples of filter paper and used scanning electron microscopes and atomic force microscopes to characterize grooves and patterns of grooves. She cut filters into pieces, reassembled the pieces with grooves facing different directions and showed they produced films with matching alignments.

Komatsu and colleagues also used heat and pressure to remove the grooves from filter paper, using the same principles involved in ironing wrinkles from clothing. They showed that films made with groove-free paper had nanotubes aligned in several directions.

Finally, starting with groove-free paper, they showed they could use a very fine reflective grating with periodic grooves to create their own patterns of grooves and that corresponding nanotube films followed those patterns.

Kono said the method is exciting because it brings a needed level of predictability to the production of 2D crystalline nanotube films.

“If the nanotubes are randomly oriented, you lose all of the one-dimensional properties,” Kono said. “Being one-dimensional is key. It leads to all of the unusual but important properties.”

While Kono group’s films are essentially 2D — as much as an inch in diameter but just a few billionths of a meter thick — the individual nanotubes behave like 1D materials, especially in terms of their optical and electronic properties.

The extraordinary optical and electronic properties of carbon nanotubes depend on their diameter and structure, or chirality. Some chiralities act like metals and others like semiconductors, and researchers have struggled for decades to find a way to make large, macroscopic objects like a wire or one of Kono’s 1-inch diameter films purely of nanotubes with one diameter and chirality.

“That’s obviously the next step,” Ghosh said. “In this study, we still used a mixture of metallic and semiconducting carbon nanotubes with a diameter distribution. The next step is to apply this new method based on intentional groove-making using a grating to achieve total control of the alignment direction.”

Kono said his team has made highly aligned 2D crystals from solutions with a diverse mixture of nanotubes.

“But when we go to a single-chirality solution, we were never satisfied with the alignment,” he said. “Now, with this knowledge of grooves, we are confident we can improve the degree of alignment in the case of single-chirality carbon nanotube films.”

Single-chirality films could open the door to applications with mind-boggling potential — for example, sheets of pure carbon that convert heat into light with almost perfect efficiency. Marrying such a sheet to a photovoltaic material could provide a way to turn heat into electric power very efficiently, creating the possibility of radiators that both cool motors and electronics while also powering them.

Kono’s lab and the research group of Rice’s Gururaj Naik demonstrated the concept for this in a 2019 paper about hyperbolic carbon nanotube films.

Single-chirality crystalline films could also be used to study new states of matter, such as exciton polaritons and Bose-Einstein condensates, and for applications that haven’t yet been envisioned, Kono said.

“At this moment, only a small number of groups in the world can make these aligned, highly dense, heavily packed carbon nanotube films,” he said. “And the work we just finished, the groove-assisted work, offers more control. This will lead to better films, new applications and new science. We are very excited.”

###

Kono is a professor of electrical and computer engineering, physics and astronomy, and materials science and nanoengineering and the director of Rice’s Applied Physics Graduate Program.

Study co-authors include Haoze Chen, a Rice undergraduate research assistant; Weilu Gao, a former Rice doctoral student now at Lightmatter Inc.; Motonori Nakamura of Asahikawa College in Asahikawa, Japan; Daeun Kim of Hokkaido University in Sapporo, Japan; and Atsuhiro Katagiri, Yohei Yomogida and Kazuhiro Yanagi of Tokyo Metropolitan University.

The research was supported by the Department of Energy (DE-FG02-06ER46308), the National Science Foundation (ECCS-1708315) and the Robert A. Welch Foundation (C-1509).

Links and resources:

The DOI of the Nano paper is: 10.1021/acs.nanolett.9b04764

A copy of the paper is available at: https:/

This release can be found online at news.rice.edu.

Follow Rice News and Media Relations via Twitter @RiceUNews.

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 4 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

If you do not wish to receive news releases from Rice University, reply to this email and write “unsubscribe” in the subject line.

Media Contact

Jeff Falk

[email protected]

713-348-6775

Original Source

http://news.

Related Journal Article

http://dx.