Credit: Universidad de Córdoba

Since the Egyptian pyramids and the Roman Coliseum were built, mankind has been searching for an affordable, versatile building material, that can be easily manufactured and transported, and, above all, is durable. Concrete, a mixture of water, cement and different kinds of minerals and rocks, has all these characteristics, which is why it is currently the most-used material in all sorts of structures. However, there is an issue that preoccupies professionals in the construction industry all over the world: the corrosion of steel bars that internally strengthen structures made of reinforced concrete. This situation causes rapid, internal deterioration of frames and may even lead to buildings collapsing.

Despite research having been done to determine which factors most influence this process, no effective solution has been found yet. We know that corrosion is caused by two agents. One of them is carbonation, as in the chemical reaction that occurs when a concrete covering comes into contact with carbon dioxide. This results in a lowering of pH levels and of its protective ability against acids. The other is the presence of chlorides, chlorine compounds, that attack steel locally and cause loss of material. This is the case that the international research group RILEM (the International Union of Laboratories and Experts in Construction Materials, Systems and Structures) focused on in their last study.

“We shared research projects performed beforehand in order to find out what is really happening in the reinforced concrete contact area when corrosion due to chlorides takes place as well as what factors mainly influence the process,” explains Mercedes Sánchez, University of Córdoba researcher who participated in the study. The main aim is to determine which factors the scientific community should focus their future studies on in order to make advances in research to fight corrosion of steel in reinforced concrete structures and to find effective solutions to avoid, or at least delay, the process.

The results of the study offer the scientific community a catalog of parameters with varying degrees of influence, highlighting which ones should no longer be priorities. In this category, we can find, for instance, the proportion of cement and water as well as the kind of cement, both of which have been widely studied already.

In addition, future scientific developments could benefit from considering other factors, such as the properties of steel, the distribution of humidity in concrete and the existence of small air voids. The data indicate a strong influence in the development of corrosion of steel bars, however these have received little scientific attention to date.

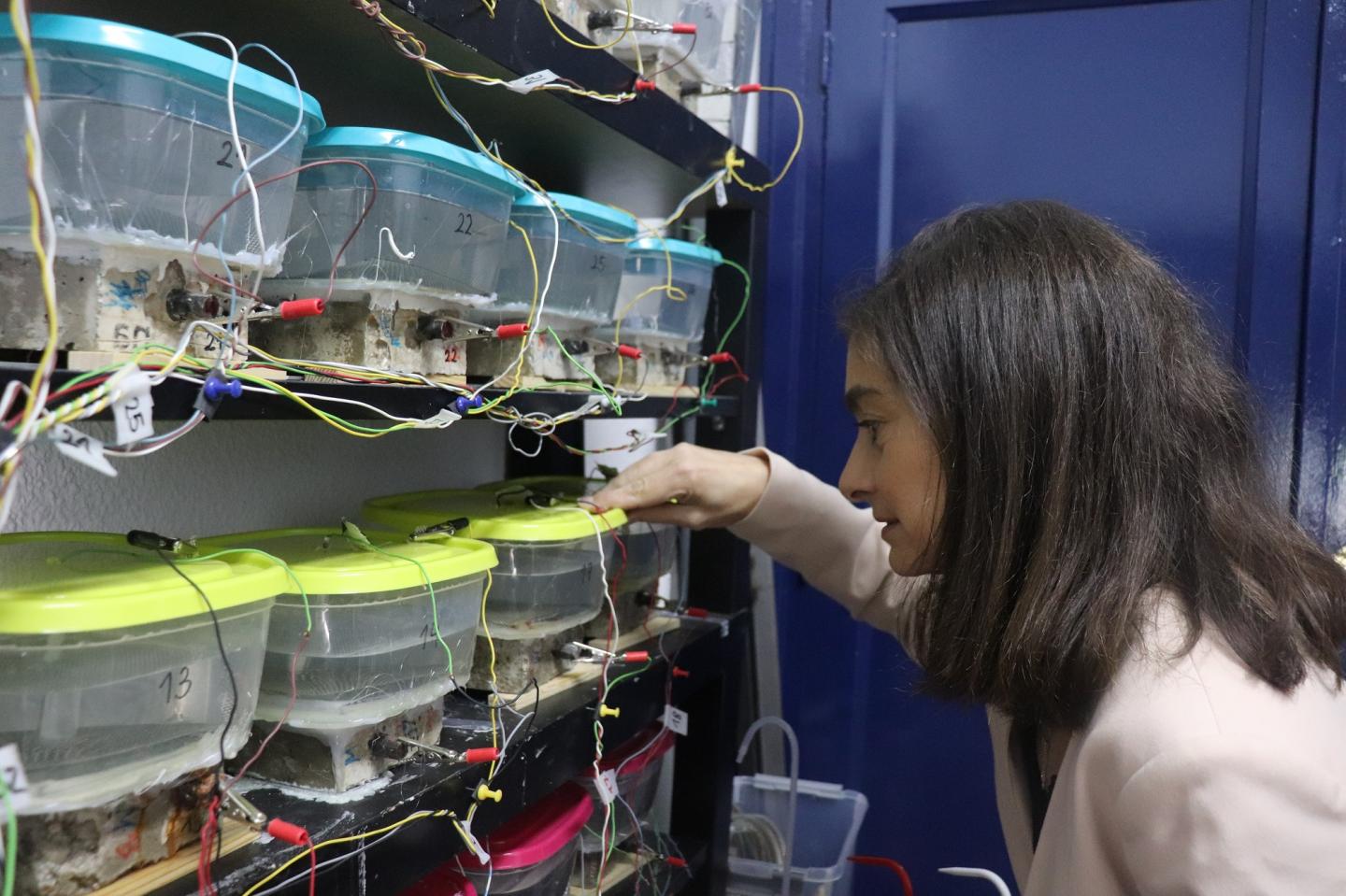

In this vein, Mercedes Sánchez is part of the University of Cordoba research team currently working on incorporating substances into concrete mixtures that will be able to trap chlorides and in doing so prevent them from getting to the steel bars and speeding up the corrosion process.

Not only is concrete a material of the present but also of the future. “Now, different kinds of concrete are being made: concrete with bacteria that are able to repair cracks, sustainable concrete made from recycled materials and made for vertical gardens,” says the researcher. Currently, her group is working on a new line of research focused on incorporating the Internet of Things to monitor reinforced steel structures in real time, so as to facilitate decision making and the inspection process.

###

Ueli M. Angst, Mette R. Geiker, Maria Cruz Alonso, Rob Polder, O. Burkan Isgor, Bernhard Elsener, Hong Wong, Alexander Michel, Karla Hornbostel, Christoph Gehlen, Raoul François, Mercedes Sanchez, Maria Criado, Henrik Sørensen, Carolyn Hansson, Radhakrishna Pillai, Shishir Mundra, Joost Gulikers, Michael Raupach, José Pacheco, Alberto Sagüés “The effect of the steel-concrete interface on chloride-induced corrosion initiation in concrete: a critical review by RILEM TC 262-SCI”. Materials and Structures. DOI: 10.1617/s11527-019-1387-0

Media Contact

Elena Lázaro

[email protected]

34-957-212-252

Related Journal Article

http://dx.