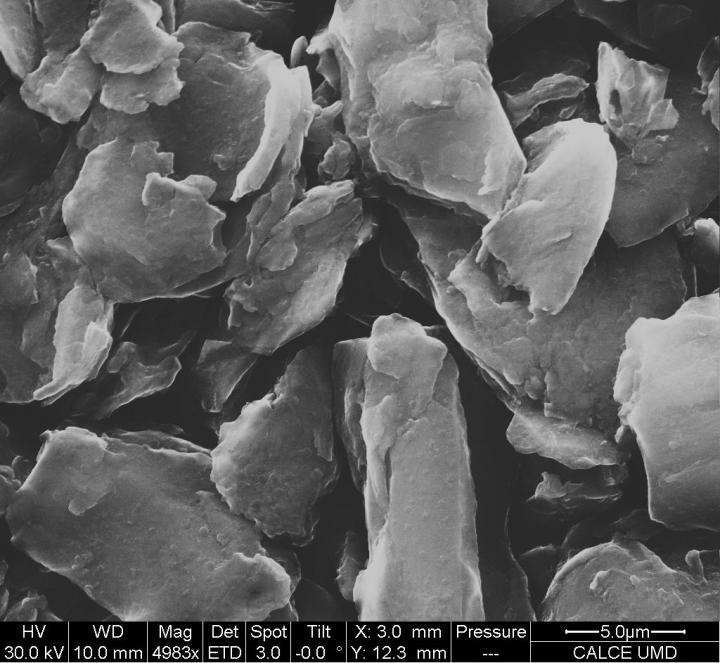

Credit: Heriot-Watt University

Exploring extreme environments can put significant operational challenges on the engineering systems we depend upon to safely explore and at times operate within.

Within high-value and safety-critical applications, such as space exploration or sub-surface drilling, the extreme and at times dynamic operating conditions within the environment, can make it challenging to understand the life expectancy of critical components and sub-systems. Hence, it’s a highly complex and at times impossible situation to accurate understand therefore predict.

To have safe, resilient and economically viable operations within these challenge environments, it is vital to understand the effect of high temperatures on critical devices, such as Electrochemical Capacitors (EC’s). In comparison to a battery, ECs, also known as supercapacitor, ultracapacitor, or electrochemical double-layer capacitor, can withstand high discharge-charge currents and thus are suitable for withstanding peak power demands. An EC’s long cycle life when operated in a high-temperature environment makes it ideal for challenging and extreme environment.

Within extreme environment systems, it is common to be operating components beyond the limits of the manufacturers recommendations. This makes the ability to understand and forecast the End of Life of such components a significant challenge. To address this challenge, in our research we focus on ECs operated at temperatures of up to 200°C, specifically the operation of ECs onboard downhole drilling equipment for geothermal or oil and gas exploration. Downhole tools are complex electromechanical systems that perform critical functions in drilling operations and are designed to withstand extreme temperatures, shocks, and vibrations.

In our research we deploy a machine learning algorithm to predict degradation trends for electrochemical double-layer capacitors beyond the knee-point onset when cycled at high temperature in an oil and gas drilling environment. Operation at high temperature accelerates EC degradation, we therefore investigate the worst-case scenario for the mentioned application.

Recently published in IEEE Access, led by Professor Flynn’s Smart Systems Group at Heriot-Watt University, and in partnership with Baker Hughes, University of Maryland and the Lloyds Register Foundation.

Professor David Flynn stated; “This research demonstrates a significant advancement in the ability to understand and predict the life expectancy of critical components. Our experimental results show that end of life, defined as a 30% decrease in capacitance, occurs at 1,000 cycles when the environmental temperature exceeds the maximum operating temperature by 30%. Using lifecycle test data, something that is not readily available and very challenging to obtain, we create machine learning model that has an average root mean squared percent error of less than 2% and a mean calibration score of 93% when referenced to a 95% confidence interval. Our model can be utilized to determine the EC degradation rate at a range of operating temperature values”.

###

Roman, D., Saxena, S., Bruns, J., Valentin, R., Pecht, M., & Flynn, D. (2021). A machine learning degradation model for electrochemical capacitors operated at high temperature. IEEE Access, 9, 25544-25553

Media Contact

susan kerr

[email protected]

Related Journal Article

http://dx.