Newly-developed SNAP device that protects surgeons performing nasal endoscopies rolling out free to NHS after rapid design and manufacture

Credit: Endoscope-i

An innovative device designed to stop patients accidentally spreading coronavirus to ear, nose and throat surgeons is rolling out free to NHS clinics across the UK.

The SNAP device – the brainchild of two Midlands surgeons, Ajith George and Chris Coulson – was developed in a matter of months thanks to a collaboration with engineers at Aston University and specialist UK-based manufacturing firms.

The need for better PPE for ear, nose and throat (ENT) surgeons was thrown into sharp focus shortly after lockdown in March, when Amged El-Hawrani, 55, an ENT specialist, became the first UK doctor to die after contracting Covid-19.

ENT surgeons performing nasendoscopies – where a small flexible tube fitted with a camera is inserted into the nose – are at risk of contracting the virus because the procedure can make patients cough and sneeze. Until now, patients have had to remove their own face masks for the endoscope to be inserted, leaving surgeons reliant only on their own PPE gear.

As a result, many hospitals have had to dramatically scale back the number of nasendoscopies they can perform. In normal times, around 500,000 procedures are performed in the NHS each year, typically to diagnose and treat diseases affecting the nose and throat including cancer and serious infections. The technique is also used in speech and language therapy, in which patients are often required to practise speaking with a tube inserted.

Currently, the NHS is only able to perform around 10% of procedures due to the risk of patients spreading coronavirus droplets around clinics, requiring deep cleaning between appointments.

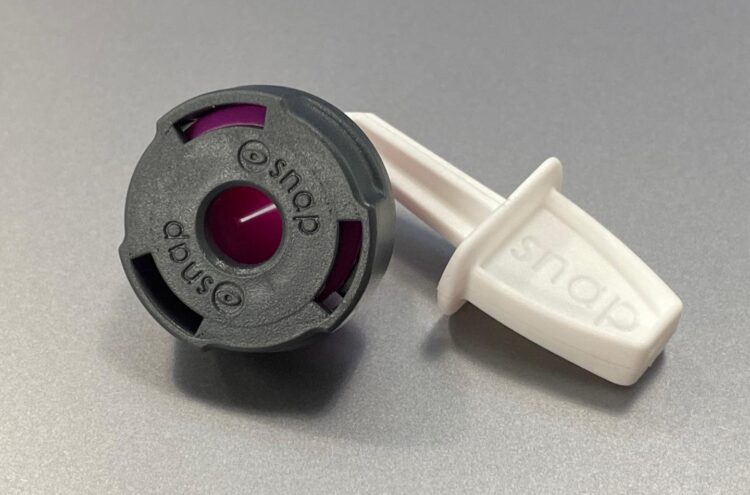

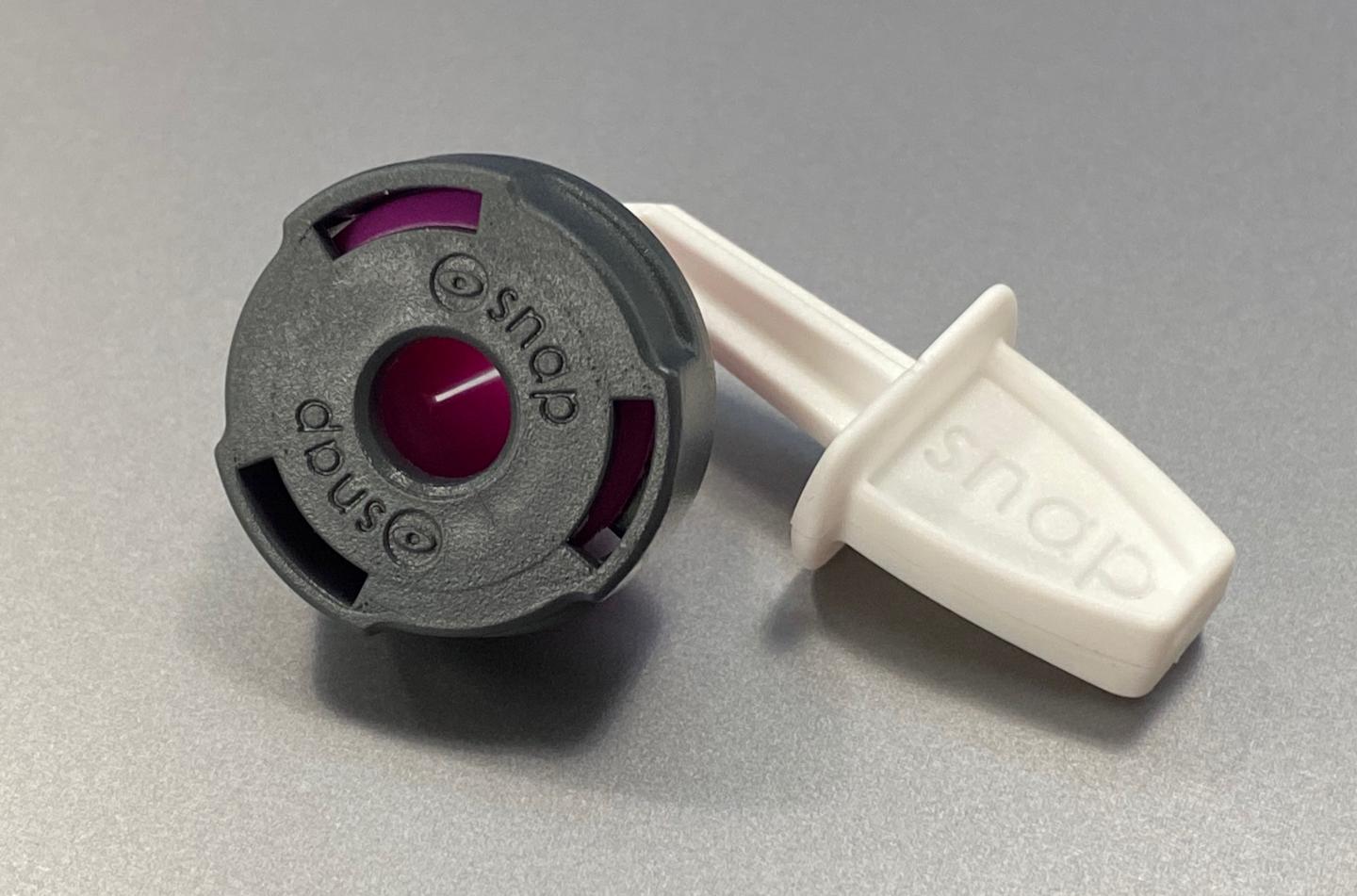

The SNAP device – comprising a two-part valve and speculum – clips onto either side of a standard surgical face mask, creating a hole for an endoscope to be inserted and for patients to keep their nose and mouth completely covered. On withdrawal of the endoscope, a one-way valve closes the hole. Any coughs, splutters or sneezes during the procedure are caught within the mask, which is disposed of at the end.

In tests, the SNAP device has been shown to dramatically reduce the spread of particles when a patient coughs, compared to either no mask or a mask with a hole cut in it. This reduction in particulate spread will reduce the likelihood of Covid-19 being transferred to clinicians.

The SNAP device was developed as a practical response to the Covid-19 crisis by doctors Ajith George and Chris Coulson, working ENT surgeons at Midlands hospitals who co-founded their spin-out company, Endoscope-i, in 2012. The firm specialises in making endoscopic adapters for smartphones that allow clinicians to carry out complex imaging work.

Mr Coulson, who works at the Queen Elizabeth Hospital in Birmingham, said:

“As surgeons ourselves, we were concerned about the safety of doctors but also about the risk of missed diagnoses and opportunities for treatment of patients. So our aim has been to produce an easy-to-use, cheap device that would allow clinicians to return to their routine practice, while minimising the risk to themselves and other staff.”

The pair won a £50,000 grant from Innovate UK to help develop their device as part of the government agency’s support for innovations designed to alleviate the impact of Covid-19.

Mr George, who is based at the Royal Stoke University Hospital in Stoke-on-Trent, added:

“It’s incredibly exciting to see this device going from concept to reality so quickly. As working surgeons, our innovation work is driven by creating things we would want to use ourselves. Covid-19 has led to heightened awareness about the spread of disease in clinical environments, so we see the SNAP device having practical applications during the pandemic and beyond.”

Dr Mark Prince, a 3D printing expert from Aston University’s College of Engineering and Physical Sciences, was seconded to Endoscope-i earlier this year and has led the design work. Using an industrial-grade 3D printer borrowed from the university during the lockdown period, he created around 2,000 prototype versions of the device from his home in Kidderminster.

He said: “It sounds disproportionate for something that is effectively such a simple idea, but each prototype had to be produced in multiples so they could be tested in clinics. With something so important, it has to be exactly right. If it helps get the NHS back to a more normal service, even in just this one specialism, it will all have been worth it.”

The final design received a CE mark approval from the Medicines and Healthcare products Regulation Agency (MHRA) and was then sent to Haverhill (Essex)-based injection-moulding specialists Form Moulds and Tooling for manufacture, before the finished SNAP products were passed on to DTR Medical in Swansea for medical sterilisation. The initial batch of 30,000 devices will be dispatched in the coming weeks, with 5,000 going out free to NHS ENT clinics nationwide.

Interest in the device has also come in from as far afield as the USA, Australia, Japan, the Netherlands and the Philippines.

###

Media Contact

James Tout

[email protected]