A team of physicists from Immanuel Kant Baltic Federal University and MISIS learned how to manage properties of amorphous microwires by adjusting internal mechanical stress

Credit: 10.1016/j.jmmm.2018.12.017

Amorphous ferromagnetic microwires are thin glass coated wires used to manufacture magnetic safety tags and in medicine. A team of physicists from Immanuel Kant Baltic Federal University and MISIS learned how to manage their properties by adjusting internal mechanical stress. The article was published in the Journal of Magnetism and Magnetic Materials.

Amorphous ferromagnetic microwires are ultra-thin glass coated wires. Their static and dynamic properties have recently become the focus of studies, because these materials are easy and cheap to produce, and their unique magnetic properties can be easily managed both in the course of manufacture and sample processing.

Currently microwires are widely used in magnetic safety tags, various detectors and in medicine for creating the state of hyperthermia.

Amorphous microwires are able to become magnetized. They also have domain structure that consists of different domains with opposite magnetization directions. The border between them is called a domain wall. There are two mechanisms used to remagnetize ferromagnetic objects – domain wall propagation and magnetization vector turning. Amorphous ferromagnetic microwires manufactured from Fe-rich alloys are remagnetized using the former method. Control over domain wall propagation is of interest from both scientific and practical points of view. Its dynamics can be regulated by choosing the composition of the alloy and the manufacture regime. The combination of these factors forms the distribution of internal mechanical stresses in a metal core which in turn determines the micromagnetic structure and the dynamics of domain wall propagation.

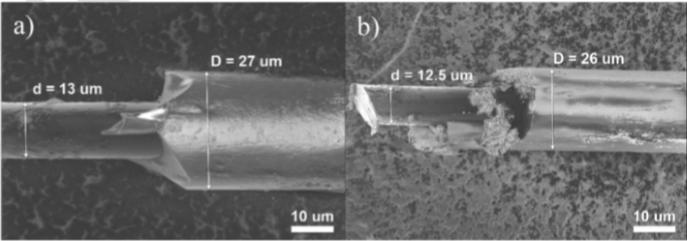

However, it is difficult to produce a microwire with specified mechanical properties. A team of scientists from Immanuel Kant Baltic Federal University analyzed the applying of stress in a metal core in the course of manufacture of microwires with similar diameters. To do so, they examined samples in different states: immediately after manufacture, after the removal of glass, and after additional annealing (heating a material up to certain temperature and keeping it at it for a required period of time followed by gradual cooling down to room temperature).

“We found out that residual stresses in the wires with identical composition are determined not only by their geometry, as we supposed. We went back to basics of the process and demonstrated the importance of the production technology choice. We also showed differences in the internal stresses of similar wires and their considerable influence at static and dynamic magnetic properties of the materials,” explained Valeria Rodionova, a co-author of the article, and the head of the laboratory of new magnetic materials at Baltic Federal University.

The study will improve the understanding of how the properties of amorphous ferromagnetic microwires and broaden the areas of their use (e.g. in applications that require domain wall propagation control, as well as in data recording and reading devices).

###

Media Contact

Julia Shkurkina

[email protected]

Related Journal Article

http://dx.