Drexel and KIST researchers report material can absorb EMI from electronic devices

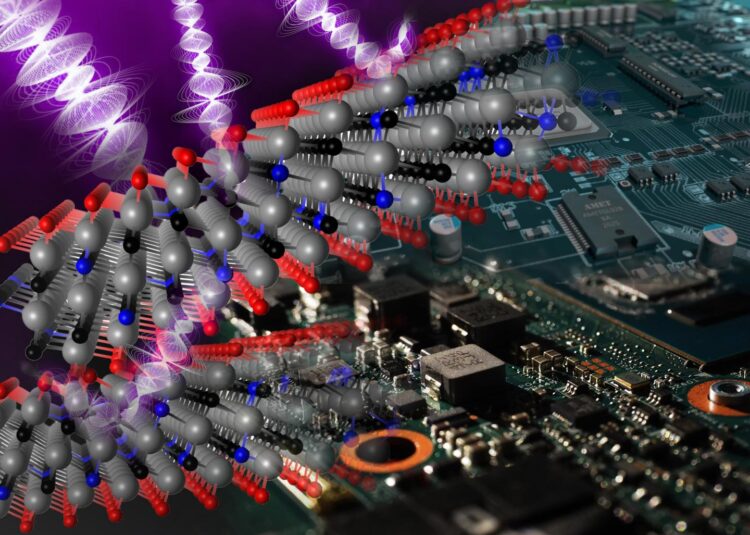

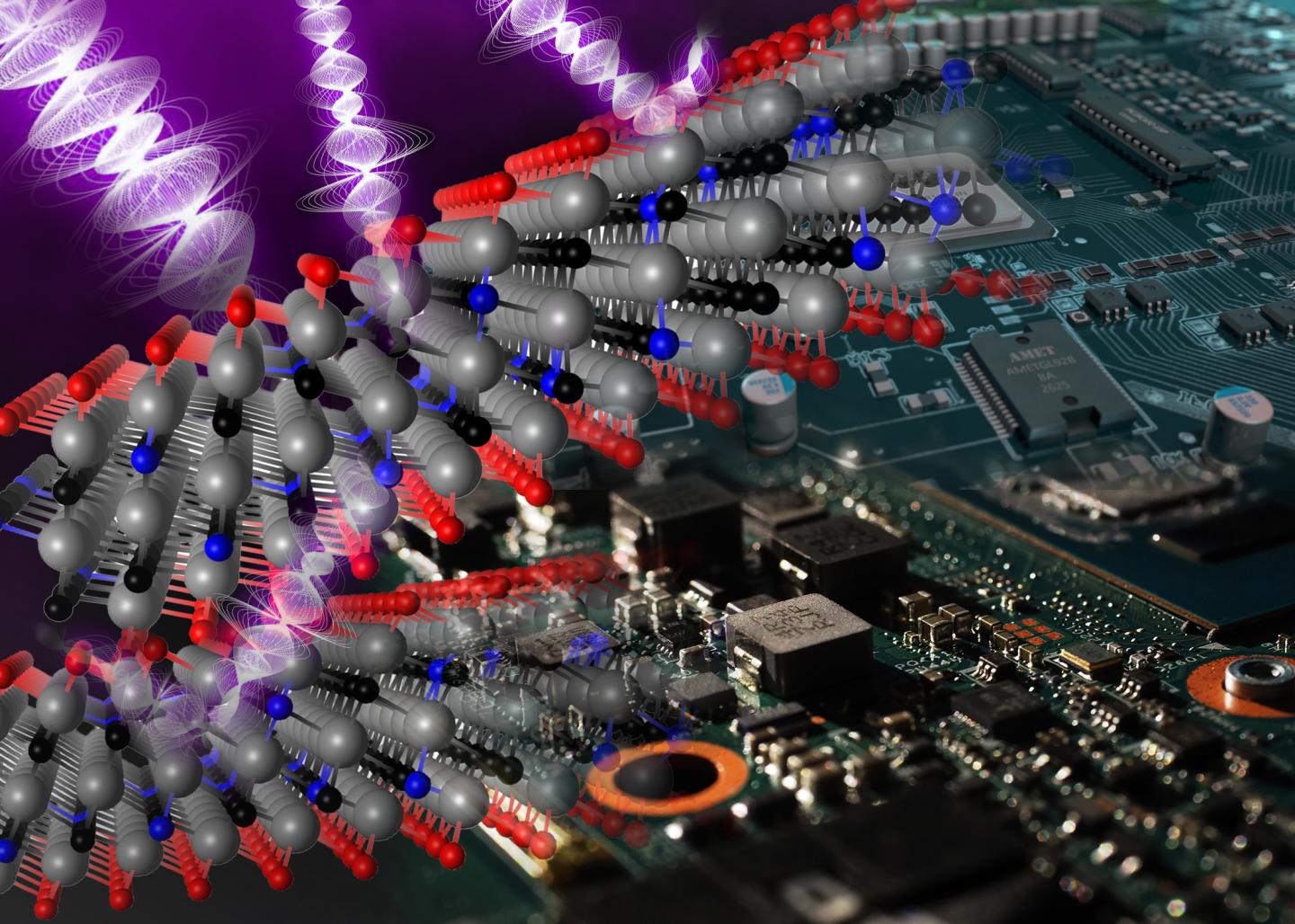

Credit: Drexel University

As we welcome wireless technology into more areas of life, the additional electronic bustle is making for an electromagnetically noisy neighborhood. In hopes of limiting the extra traffic, researchers at Drexel University have been testing two-dimensional materials known for their interference-blocking abilities. Their latest discovery, reported in the journal Science, is of the exceptional shielding ability of a new two-dimensional material that can absorb electromagnetic interference rather than just deflecting back into the fray.

The material, called titanium carbonitride, is part of a family of two-dimensional materials, called MXenes, that were first produced at Drexel in 2011. Researchers have revealed that these materials have a number of exceptional properties, including impressive strength, high electrical conductivity and molecular filtration abilities. Titanium carbonitride’s exceptional trait is that it can block and absorb electromagnetic interference more effectively than any known material, including the metal foils currently used in most electronic devices.

“This discovery breaks all the barriers that existed in the electromagnetic shielding field. It not only reveals a shielding material that works better than copper, but it also shows an exciting, new physics emerging, as we see discrete two-dimensional materials interact with electromagnetic radiation in a different way than bulk metals,” said Yury Gogotsi, PhD, Distinguished University and Bach professor in Drexel’s College of Engineering, who led the research group that made this MXene discovery, which also included scientists from the Korea Institute of Science and Technology, and students from Drexel’s co-op partnership with the Institute.

While electromagnetic interference – “EMI” to engineers and technologists – is noticed only infrequently by the users of technology, likely as a buzzing noise from a microphone or speaker, it is a constant concern for the engineers who design it. The things that EMI is interfering with are other electrical components, such as antennas and circuitry. It diminishes electrical performance, can slow data exchange rates and can even interrupt the function of devices.

Electronics designers and engineers tend to use shielding materials to contain and deflect EMI in devices, either by covering the entire circuit board with a copper cage, or, more recently by wrapping individual components in foil shielding. But both of these strategies add bulk and weight to the devices.

Gogotsi’s group discovered that its MXene materials, which are much thinner and lighter than copper, can be quite effective at EMI shielding. Their findings, reported in Science four years ago, indicated that a MXene called titanium carbide showed the potential to be as effective as the industry-standard materials at the time, and it could be easily applied as a coating. This research quickly became one of the most impactful discoveries in the field and inspired other researchers to look at other materials for EMI shielding.

But as the Drexel and KIST teams continued to inspect other members of the family for this application, they uncovered the unique qualities of titanium carbonitride that make it an even more promising candidate for EMI shielding applications.

“Titanium carbonitride has a very similar structure by comparison to titanium carbide – they’re actually identical aside from one replacing half of its carbon atoms with nitrogen atoms – but titanium carbonitride is about an order of magnitude less conductive,” said Kanit Hantanasirisakul, a doctoral candidate in Drexel’s Department of Materials Science and Engineering. “So we wanted to gain a fundamental understanding of the effects of conductivity and elemental composition on EMI shielding application.”

Through a series of tests, the group made a startling discovery. Namely, that a film of the titanium carbonitride material -many times thinner than the thickness of a strand of human hair – could actually block EMI interference about 3-5 times more effectively than a similar thickness of copper foil, which is typically used in electronic devices.

“It’s important to note that we didn’t initially expect the titanium carbonitride MXene to be better compared to the most conductive of all MXenes known: titanium carbide,” Hantanasirisakul said. “We first thought there might be something wrong with the measurements or the calculations. So, we repeated experiments over and over again to make sure we did everything correctly and the values were reproducible.”

Perhaps more significant than the team’s discovery of the material’s shielding prowess is their new understanding of the way it works. Most EMI shielding materials simply prevent the penetration of the electromagnetic waves by reflecting it away. While this is effective for protecting components, it doesn’t alleviate the overall problem of EMI propagation in the environment. Gogotsi’s group found that titanium carbonitride actually blocks EMI by absorbing the electromagnetic waves.

“This is a much more sustainable way to handle electromagnetic pollution than simply reflecting waves that can still damage other devices that are not shielded,” Hantanasirisakul said. “We found that most of the waves are absorbed by the layered carbonitride MXene films. It’s like the difference between kicking litter out of your way or picking it up – this is ultimately a much better solution.”

This also means that titanium carbonitride could be used to individually coat components inside a device to contain their EMI even while they are being placed closely together. Companies like Apple have been trying this containment strategy for several years, but with success limited by the thickness of the copper foil. As devices designers strive to make them ubiquitous by making them smaller, less noticeable and more integrated, this strategy is likely to become the new norm.

The researchers suspect that titanium carbonitride’s uniqueness is due to its layered, porous structure, which allows EMI to partially penetrate the material, and its chemical composition, which traps and dissipates the EMI. This combination of characteristics emerges within the material when it is heated in a final step of formation, called annealing.

“It was a counterintuitive finding. EMI shielding effectiveness typically increases with electrical conductivity. We knew that heat treatment can increase conductivity, so we tried that with the titanium carbonitride to see if it would improve its shielding ability. What we discovered is that it only marginally improved its conductivity, but vastly boosted its shielding effectiveness,” Gogotsi said. “This work motivates us, and should motivate others in the field, to look into properties and applications of other MXenes, as they may show even better performance despite being less electrically conductive.”

The Drexel team has been expanding its scope and has already examined EMI shielding capabilities of 16 different MXene materials – about half of all MXenes produced in its lab. It plans to continue its investigation of titanium carbonitride to better understand its unique electromagnetic behavior, in hope of predicting hidden abilities in other materials.

###

In addition to Gogotsi and Hantanasirisakul, Aamir Iqbal, Faisal Shahzad, Myung-Ki Kim, Hisung Kwon, Junpyo Hong, Hyerim Kim, Daesin Kim and Chong Min Koo; researchers from Korea Institute of Science and Technology (KIST) contributed to this research.

Media Contact

Britt Faulstick

[email protected]

Related Journal Article

http://dx.