A two-part water-based gel made of synthetic DNA could bring the Heriot-Watt inventors of a 3D bio printer closer to being able to print organs for transplant, or to replace animal testing.

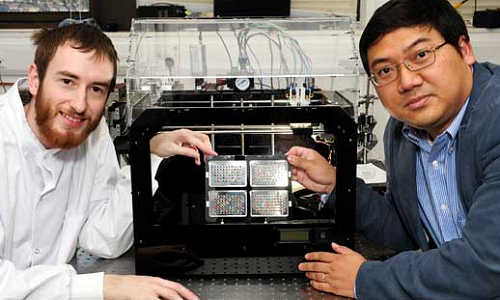

Members of the IB3 team PhD student Alan Faulkner-Jones and Dr Will Shu

The Heriot-Watt team, led by Professor Rory Duncan, head of the Institute of Biological Chemistry, Biophysics and Bioengineering (IB3) and Dr Will Shu, also of IB3, at the University’s School of Engineering and Physical Sciences faced two main challenges: finding a matrix or scaffold to support the live cells in 3D, and being able to produce a consistent product which would not be rejected by transplant recipients.

Professor Duncan explains. “The first challenge was that if we used a normal gel it was not possible to mix live cells with it for 3D printing. Colleagues at Tsinghua University in Beijing have developed a gel which, like some proprietary glues, comes as two separate liquids into which cells can be added. These do not turn into a gel until the two liquids are actually mixed together during the printing process.”

Dr Shu said, “Using the new gel in combination with our delicate 3D printing system, which does not involve heat, UV, salt or other harsh conditions to make the printed 3D object set, we have been able to demonstrate we can produce a three dimensional matrix containing highly viable live cells.

“Most importantly, working with the wider team led by Professor Duncan here at Heriot-Watt, we have also have run specialised imaging tests to prove that the cells we used remained alive and functioning at sub-cellular level after this process was complete.”

Another other major advantage for the team is the ability to manipulate the exact rigidity of the gel and the printed object, as well as assuring consistency in the end product.

Traditionally 3D printing gels have been based on natural products, for example collagen or materials extracted from seaweed, and not only is it hard to mix the live cells into these it is also hard to control the rigidity of the gel and to standardise it for production purposes. The new two-part synthetic DNA-based gel answers those challenges as well as producing a matrix which would not be rejected by recipients if the team reach their long-term goal of printing artificial organs for transplant.

Collaborative research

The breakthrough is, says Professor Duncan, a showcase for the benefits of teamwork. “This is a wonderful example of working across disciplines and across geographical boundaries. Chemists, engineers and biologists have come together from Scotland and China, to produce, test and demonstrate the benefits of this product.”

Professor Shu agrees. “Our eventual aim is to 3D print organs for transplant, as well as producing alternatives to the testing of drugs on animals. This new gel in combination with our 3D live cell printer is a huge step forward towards these potential long-term medical benefits.”

The joint project features in latest edition of Angewandte Chemie International.

Story Source:

The above story is based on materials provided by Heriot-Watt University.