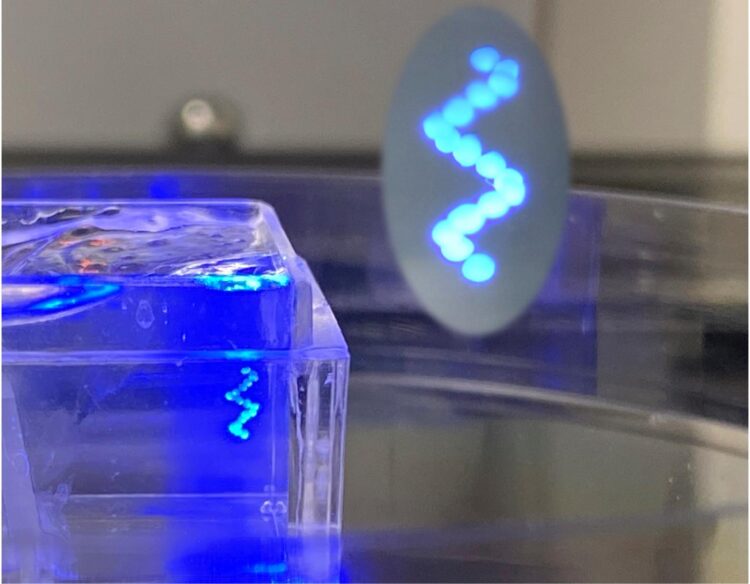

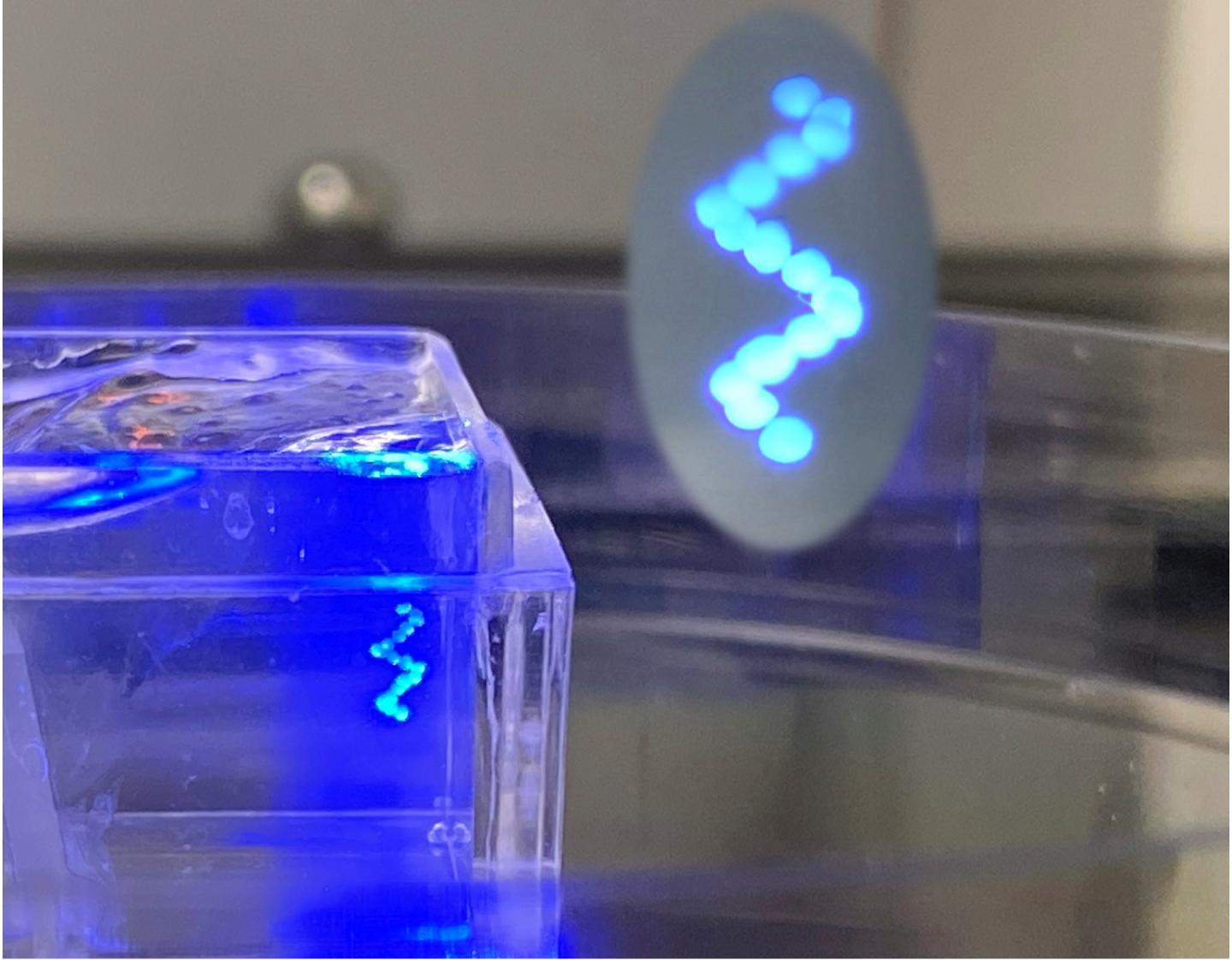

Credit: Ozbolat Lab at Penn State

The eventual creation of replacement biological parts requires fully three-dimensional capabilities that two-dimensional and three-dimensional thin-film bioprinting cannot supply. Now, using a yield stress gel, Penn State engineers can place tiny aggregates of cells exactly where they want to build the complex shapes that will be necessary to replace bone, cartilage and other tissues.

“The reason why this is important is that the current cell aggregate bioprinting techniques can’t make complicated configurations and is mostly in 2D and 3D thin films or simple configurations,” said Ibrahim T. Ozbolat, Hartz Family Career Development Associate Professor of Engineering Science and Mechanics. “If we want complicated 3D, we need a supportive field.”

That supportive field, the researchers report today (Oct. 16) in Communication Physics is a yield stress gel. Yield stress gels are unusual in that without stress they are solid gels, but under stress, they become liquid.

The researchers are using an aspiration-assisted bioprinting system that they demonstrated earlier this year to pick up aggregates of cells and place them precisely inside of the gel. The stress of the aspiration nozzle against the gel liquefies it, but once the aspiration nozzle releases cell aggregates and withdraws, the gel returns to solid again, self-healing. The tiny balls of cells rest upon each other and self-assemble, creating a solid tissue sample within the gel.

The researchers can place different types of cells, in small aggregates, together to form the required shape with the required function. Geometric shapes like the cartilage rings that support the trachea, could be suspended within the gel.

“We tried two different types of gels, but the first one was a little tricky to remove,” said Ozbolat. “We had to do it through washing. For the second gel, we used an enzyme that liquefied the gel and removed it easily.”

“What we are doing is very important because we are trying to recreate nature,” said Dishary Banerjee, postdoctoral researcher in engineering science and mechanics. “In this technology it is very important to be able to make free-form, complex shapes from spheroids.”

The researchers used a variety of approaches, creating theoretical models to get a physical understanding of what was happening. They then used experiments to test if this method could produce complex shapes.

###

Also working on this project from Penn State were recent graduate Bugra Ayan, now in medical school at Stanford University; Nazmiye Celik, graduate student in engineering science and mechanics; Zhifeng Zhang, former graduate student in engineering science and mechanics; Kui Zhou, postdoctoral scholar in engineering science and mechanics, Myoung Hwan Kim, graduate student in bioengineering; Yang Wu, postdoctoral scholar in engineering science and mechanics; and Francesco Costanzo, professor of engineering science and mechanics, mechanical engineering and bioengineering.

The National Science Foundation, Osteology Foundation, National Institute of Dental and Craniofacial Research, and the Lysosomal and Rare Disorders Research and Treatment Center supported this work.

Media Contact

A’ndrea Elyse Messer

[email protected]

Related Journal Article

http://dx.