During experiments on high-performance wire arc additive manufacturing researchers produced a metal with unique ductility

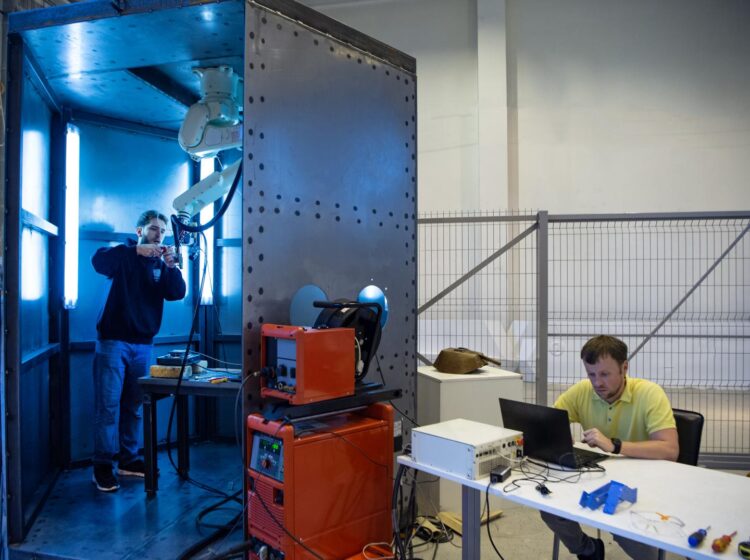

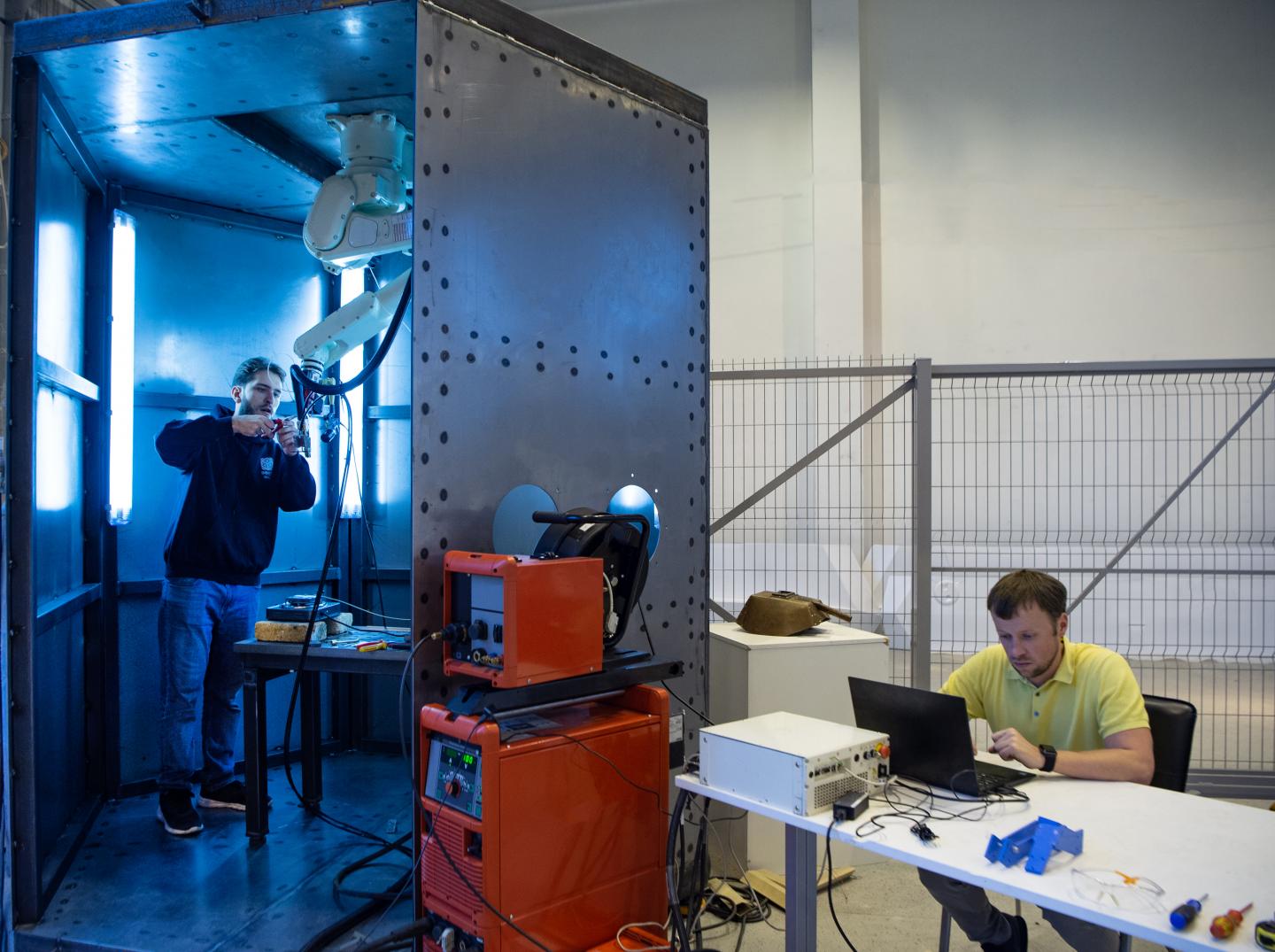

Credit: Peter the Great St.Petersburg Polytechnic University

During experiments on high-performance Wire Arc Additive Manufacturing (WAAM) researchers from Peter the Great St.Petersburg Polytechnic University (SPbPU) produced a metal with unique ductility. The ductility is three times higher than specified in the standard. The research results were published in a prestigious journal – “Materials & Design“.

Increase of WAAM productivity led to discovery of unique properties of aluminum. Elongation of specimens during tensile tests of produced metal increased from 12 to 41% compared to its standard properties for the same chemical composition. It means that material will be able to perform longer with the same loading conditions. The developed WAAM technology with higher process rates helps to achieve better material performance.

“In fact, this discovery can change the way of the components design, since now we are able to print high-scale metal object with triple loading capacity. Mechanical properties of metal are always considered with a margin, in our case this margin is several times higher than the specified in standard. This technology could be interesting for many industries, for example for Aerospace sector where we have a partner – S7 R&D Center. The manufactured material will be able to withstand deformations caused by load in Space for a longer time, ” said Oleg Panchenko, Head of the Laboratory of Lightweight Materials and Structures SPbPU.

The solidification rate increase of metal has led to improvement in ductile properties of aluminum. It was achieved by increase of build rate up to 2.2 kg/h. Due to the lack of special equipment for 3D printing (WAAM) in the market initially the utilitarian goal of the research was to increase productivity.

In future, the researchers plan to increase solidification rate even more.

“This will help to trace dependence of material properties on additive manufacturing build rate. We have discovered a way to achieve unique properties and we are willing to move this border of knowledge further”, says Oleg Panchenko.

The scientists also plan studying properties of the produced material under cyclic (fatigue) loading since the published study was based on the analysis performed for static loading. Researchers plan to test the hypothesis that materials with increased ductility show better fatigue performance.

###

Media Contact

Raisa Bestugina

[email protected]

Related Journal Article

http://dx.