Credit: Copyright ©2020 American Chemical Society

With the global spread of coronavirus infections, personal protective equipments especially hygeine face masks are receiving much attention. Masks are essential items for the primary protection of the respiratory tract from viruses and bacteria that are transmitted through the air as droplets.

N95 masks are currently difficult to obtain, so there is an urgent need for a safe method of prolonging their usability through disinfection and reuse with minimal loss of the performance and integrity. Particulate filtration and air permeability are key factors in determining performance while cleaning and disinfecting N95 certified masks. This is crucial in preventing infections. Shinshu University has a track record of conducting research on production methods and applications of “nanofiber non-woven fabric” since before the coronavirus outbreak.

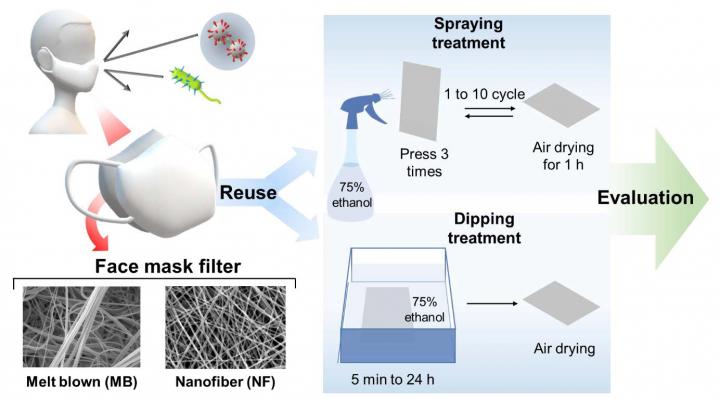

With this current social backdrop, a research team led by Professor Ick Soo Kim of Shinshu University’s Institute for Fiber Engineering (IFES) with Ph.D. students Sana Ullah and Azeem Ullah and Professor Cha Hyung Joon of POSTECH (specially invited professor of IFES) with Ph.D. students Jaeyun Lee and Yeonsu Jeong looked into the effectiveness of sterilizing N95 masks. They looked at commercially available melt-blown nonwoven fabric N95 masks and nonwoven nanofiber masks with N95 filters. They examined the filtration efficiency, comfort of the wearer, and filter shape change after washing and disinfecting. The methods of disinfection test were directly spraying 75% ethanol on the mask filter and air drying, and soaking the mask filter in 75% ethanol solution for 5 minutes to 24 hours and leaving it to air dry naturally.

Filtration efficiency of both of the filters (melt-blown filter and the nanofiber filter) was 95% or more before use, which indicates that the respiratory organs of the wearer can be effectively protected. The tests also clarified that the inside of the filter can be effectively sterilized by spraying ethanol 3 times or more or immersing it in an ethanol solution for more than 5 minutes. However, when the mask was reused after the ethanol disinfection, the filtration efficiency of the melt-blown filter decreased to 64%. On the other hand, the nanofiber filter did not deteriorate in filter performance even after 10 or more uses.

Melt-blown filter works on the principle of electrostatic charge for removal of particulate matter, as in the result of ethanol spraying or dipping the electrostatic charge on the surface of melt-blown filter was lost, so efficiency of melt-blown filter was significantly decreased. On the other hand, filtration mechanism of nanofiber filter is independent of static charge and fully dependent on pore diameter, pore distribution, and morphology of nanofibers. As in the result of disinfection, morphology of nanofibers was not affected, thus it also maintained it’s filtration as optimum as it was before use.

In addition, the nanofiber filter has higher heat emission and carbon dioxide emission performance than the melt-blown filter, and exhibits excellent breathability. Similarly, it was confirmed that the nanofiber filter had lower cytotoxicity than the melt-blown filter when a safety experiment using human skin and vascular cells was performed.

As stated above, both mask filters have similar filtering performance at the time of first use, but after disinfecting and reusing, the nanofiber filter does not exhibit performance deterioration. In other words, nanofiber filters can be easily sterilized with ethanol at home and reused multiple times.

“This research is an experimental verification of the biological safety of nanofiber masks and the maintenance of filtration efficiency after washing, which has recently become a problem,” Professor Cha Hyung Joon states, who co-presided the research. Professor Ick Soo Kim hopes that nanofiber masks will serve as a means of prevention in the second and third wave of coronavirus infections.

###

The results of this research were published online as a cover article in the international academic journal ACS Applied Nano Materials published by the American Chemical Society.

Media Contact

Hitomi Thompson

[email protected]

Related Journal Article

http://dx.