A new armour-plated superhydrophobic material has been developed for potential uses in medical equipment, solar panels and more

Credit: Aalto University

Superhydrophobic surfaces repel water like nothing else. This makes them extremely useful for antimicrobial coatings – as bacteria, viruses and other pathogens cannot cling to their surfaces. However, superhydrophobic surfaces have one major flaw – they are extremely susceptible to cuts, scratches or dents. If a superhydrophobic surface gets damaged, the damaged area can trap liquids and the benefits of the coating are lost. Now, however, a collaboration between researchers in China and Finland has developed an armour-plated superhydrophobic surface which can take repeated battering from sharp and blunt objects, and still repel liquids with world-record effectiveness.

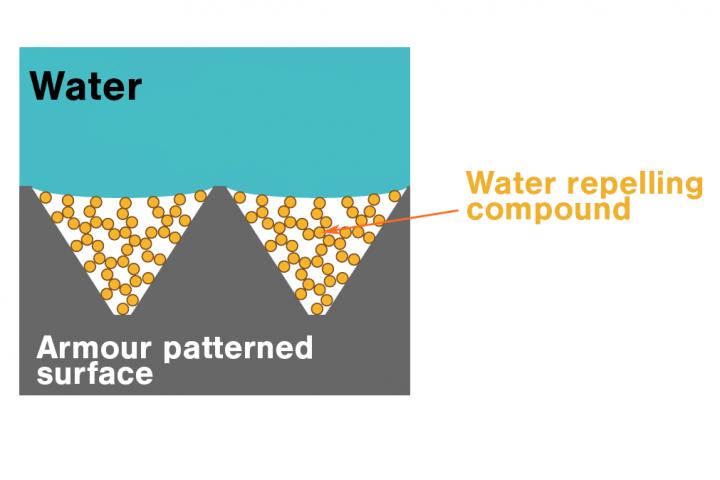

The research – which is the cover feature of this week’s issue of Nature – has designed superhydrophobic surfaces that can be made out of metal, glass, or ceramic. The superhydrophobic properties of the surface come from nano-sized structures spread all over it. The trick is to pattern the surface of the material with a honeycomb-like structure of tiny inverted pyramids. The fragile water-repellent chemical is then coated on the inside the honeycomb. This prevents any liquid from sticking to the surface, and the fragile chemical coating is protected from damage by the pyramid’s walls.

“The armour can be made from almost any material, it’s the interconnection of the surface frame that makes it strong and rigid,” says Professor Robin Ras, a physicist at Aalto University whose research group was part of the project. “We made the armour with honeycombs of different sizes, shapes and materials. The beauty of this result is that it is a generic concept that fits for many different materials, giving us the flexibility to design a wide range of durable waterproof surfaces.”

As well as their useful antimicrobial properties for biomedical technology, superhydrophobic surfaces can also be used more generally in any application requiring a liquid-repellent surface. One example is photovoltaics, where the build-up of moisture and dirt over time blocks the amount of light they can absorb, which reduces electricity production. Making a solar panel out of a superhydrophobic glass surface would maintain their efficiencies over long periods of time. Furthermore, as solar cells are often on roof tops and other difficult to reach locations, the repellent coatings would cut down the amount of cleaning that is needed.

“By using the decoupled design, we introduce a new approach for designing a robust superhydrophobic surface. Our future work would be to push this method further, and to transfer robust superhydrophobic surfaces to different materials and its commercialization” said Professor Xu Deng, the leader of the group at the University of Electronic Science and Technology of China in Chengdu who took part in this research.

Other desirable applications for superhydrophobic surfaces include in machines and on vehicles, where conditions can be very tough for brittle materials for long periods of time. To simulate these working environments, the researchers subjected their new surfaces to extreme conditions, including baking them at 100 °C nonstop for weeks, immersing them in highly corrosive liquids for hours, blasting them with high-pressure water jets, and subjecting them to physical exertion in extreme humidity. The surfaces were still able to repel liquid as effectively as before.

Now that the strengths of this new material design have been demonstrated, future research will explore its broad potential in real-world applications.

###

The work was supported by National Natural Science Foundation of China, the European Research Council, the Academy of Finland, Aalto University, and Business Finland.

The full paper, Design of robust superhydrophobic surfaces can be read online at https:/

Media Contact

Professor Robin Ras

[email protected]

Related Journal Article

http://dx.