Credit: MIT

Scientists at Nanyang Technological University, Singapore (NTU Singapore), Massachusetts Institute of Technology (MIT), and Brown University have developed new approaches that significantly improve the accuracy of an important material testing technique by harnessing the power of machine learning.

Nano-indentation – the process of poking a sample of a material with a sharp needle-like tip to see how the material responds by deforming – is important in many manufacturing applications, but its poor accuracy in obtaining certain key mechanical properties of a material, has prevented it from being used widely in industry.

Using the standard nano-indentation process and feeding its experimentally-measured data to a neural network machine learning system, the scientists developed and ‘trained’ the system to predict samples’ yield strength 20 times more accurately than existing methods.

The new analytical technique could reduce the need for time-consuming and costly computer simulations, to ensure that manufactured parts used in structural applications such as airplanes and automobiles, and those made from digital manufacturing techniques such as 3D printing are safe to use in real-life conditions.

The senior corresponding author of this paper, NTU Distinguished University Professor Subra Suresh, who is also the university president, said: “By incorporating the latest advances in machine learning with nano-indentation, we have shown that it is possible to improve the precision of the estimates of material properties by as much as 20 times. We have also validated this system’s predictive capability and accuracy enhancement on conventionally manufactured aluminum alloys and 3D-printed titanium alloys. This points to our method’s potential for digital manufacturing applications in Industry 4.0, especially in areas such as 3D-printing.”

The findings will be published in the Proceedings of the National Academy of Sciences of the United States of America this week.

Material benefits from a hybrid approach

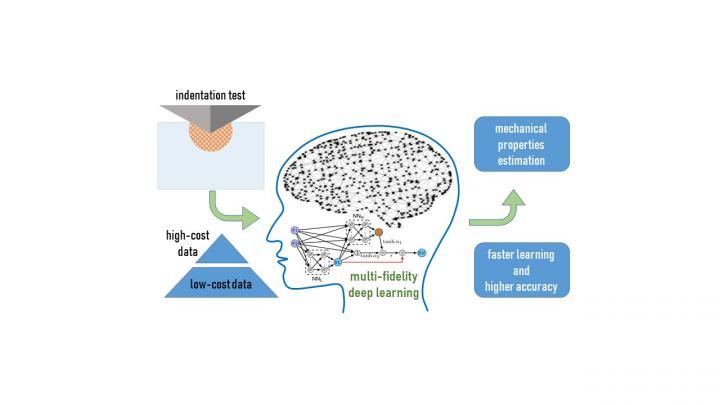

The method, developed by the team of researchers from NTU, MIT, and Brown, is a hybrid approach that combines machine learning with state-of-the-art nano-indentation techniques (See illustration in the Note to Editors).

The process first starts with pressing a hard tip – typically made of a material like diamond – into the sample material at a controlled rate with precisely calibrated force, while constantly measuring the penetration depth of the tip into the material being deformed.

The challenge arises because the process of decoding the resulting experimentally-measured data is extremely complex and is currently preventing the widespread use of the nano-indentation testing technique, in the manufacturing of aircraft and automobiles, according to NTU Professor Upadrasta Ramamurty, who holds the President’s Chair in Mechanical and Aerospace Engineering and Materials Science and Engineering at NTU.

To improve accuracy in such situations, the NTU-MIT-Brown team developed an advanced neural network – a computing system modelled loosely on the human brain – and ‘trained’ it with a combination of real experimental data and computer-generated data. Their “multi-fidelity” approach real experimental data as well as physics-based and computationally simulated “synthetic” data (from both two-dimensional and three-dimensional computer simulations) with deep learning algorithms.

MIT principal research scientist and NTU Visiting Professor Ming Dao said that previous attempts at using machine learning to analyse material properties mostly involved the use of “synthetic” data generated by the computer under unrealistically perfect conditions – for instance where the shape of the indenter tip is perfectly sharp, and the motion of the indenter is perfectly smooth. The measurements predicted by machine learning were inaccurate as a result.

Training the neural network initially with synthetic data, then incorporating a relatively small number of real experimental data points, however, can substantially improve the accuracy of the results, the team found.

They also report that the training with synthetic data can be done ahead of time, with a small number of real experimental results to be added for calibration when it comes to evaluating the properties of actual materials.

Prof Suresh said: “The use of real experimental data points helps to compensate for the ideal world that is assumed in the synthetic data. By using a good mix of data points from the idealised and real-world, the end result is drastically reduced error.”

In addition to Prof Subra Suresh, Prof Ming Dao and Prof Upadrasta Ramamurty, the list of authors include graduate student Punit Kumar from NTU, and Prof George Em Karniadakis and graduate student, Lu Lu, from Brown University.

###

Media Contact

Foo Jie Ying

[email protected]