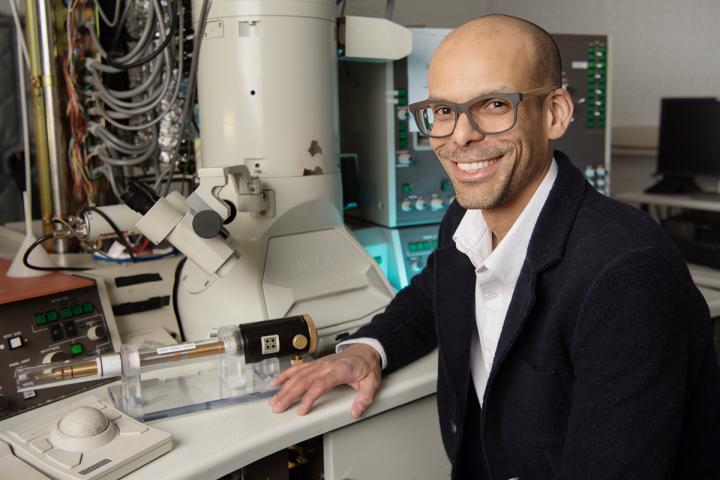

Credit: Photo by Steph Adams

CHAMPAIGN, Ill. — Researchers have demonstrated a new method for testing microscopic aeronautical materials at ultra-high temperatures. By combining electron microscopy and laser heating, scientists can evaluate these materials much more quickly and inexpensively than with traditional testing.

The findings of the new study, conducted by Shen Dillon, a professor of materials science and engineering at the University of Illinois at Urbana-Champaign, and collaborators from Sandia Laboratories, are published in the journal Nano Letters.

A decade ago, advancements in aeronautical materials involved testing large, expensive models and years of development. Scientists and engineers now use micro-scale experimentation to help create new materials and understand the chemical and physical properties that lead to material failure.

“Micro-scale mechanical testing provides opportunities to break the materials down into their components and see defects at the atomic level,” Dillon said.

Until now, researchers have been unable to conduct successful micro-scale materials tests at the extreme temperatures experienced by critical components during flight.

“Unfortunately, it’s really difficult to perform experiments with new materials or combinations of existing materials at ultra-high temperatures above 1,000 C because you run into the problem of destroying the testing mechanisms themselves,” Dillon said.

This temperature barrier has slowed the development of new materials for commercial applications such as rockets and vehicles, which require testing at temperatures well above the current research’s limit of “a few hundred degrees Celsius,” he said. “The method we demonstrate in the paper will significantly reduce the time and expense involved in making these tests possible.”

Their ultra-high temperature test combined two commonly used tools in a unique way. Using a transmission electron microscope and targeted laser heating, they were able to see and control where and how the material deformed at the highest temperature possible before the sample evaporated.

“We were able to bring the laser together with the mechanical tester so precisely with the TEM that we could heat the sample without overheating the mechanical tester,” Dillon said. “Our test allows you to grow a thin film of the material without any special processing and then put it in the microscope to test a number of different mechanical properties.”

As proof of concept, the study tested zirconium dioxide – used in fuel cells and thermal barrier coatings – at temperatures up to 2,050 C, “a temperature well above anything that you could do previously,” Dillon said.

Dillon says the paper will result in “more people using this technique for high-temperature tests in the future because they are much easier to do and the engineering interest is definitely there.”

###

Dillon also is affiliated with the Materials Research Lab at Illinois. The National Science Foundation and Army Research Office supported this study.

Editor’s notes:

To reach Shen Dillon, call 217-244-5622; email [email protected].

The paper “In situ transmission electron microscopy for ultrahigh temperature mechanical testing of ZrO2” is available online and from the U. of I. News Bureau. DOI: 10.1021/acs.nanolett.9b04205

Media Contact

Steph Adams

[email protected]

217-333-2032

Original Source

https:/

Related Journal Article

http://dx.