Rice materials scientists detail unexpected distortions in self-assembling polymers

Credit: Tommy LaVergne/Rice University

HOUSTON – (Oct. 28, 2019) – What appears to be an impossibly complicated maze is actually quite simple. Two complicated mazes, intertwined but not touching, tell a different story.

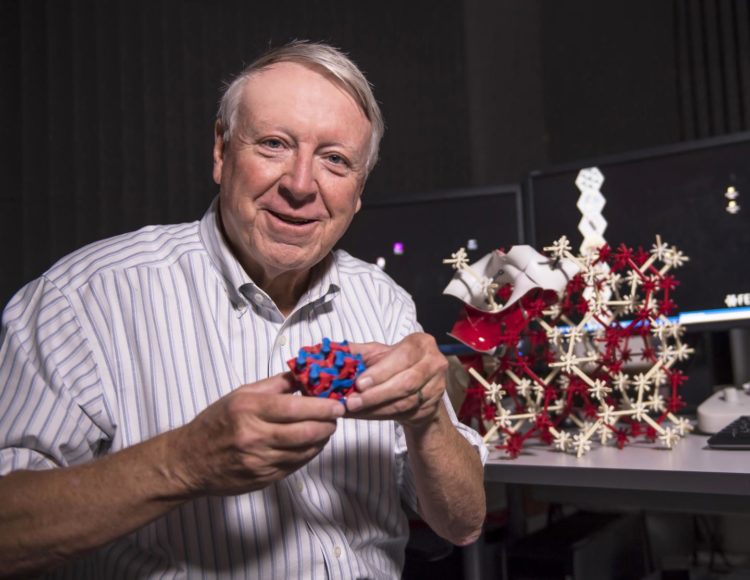

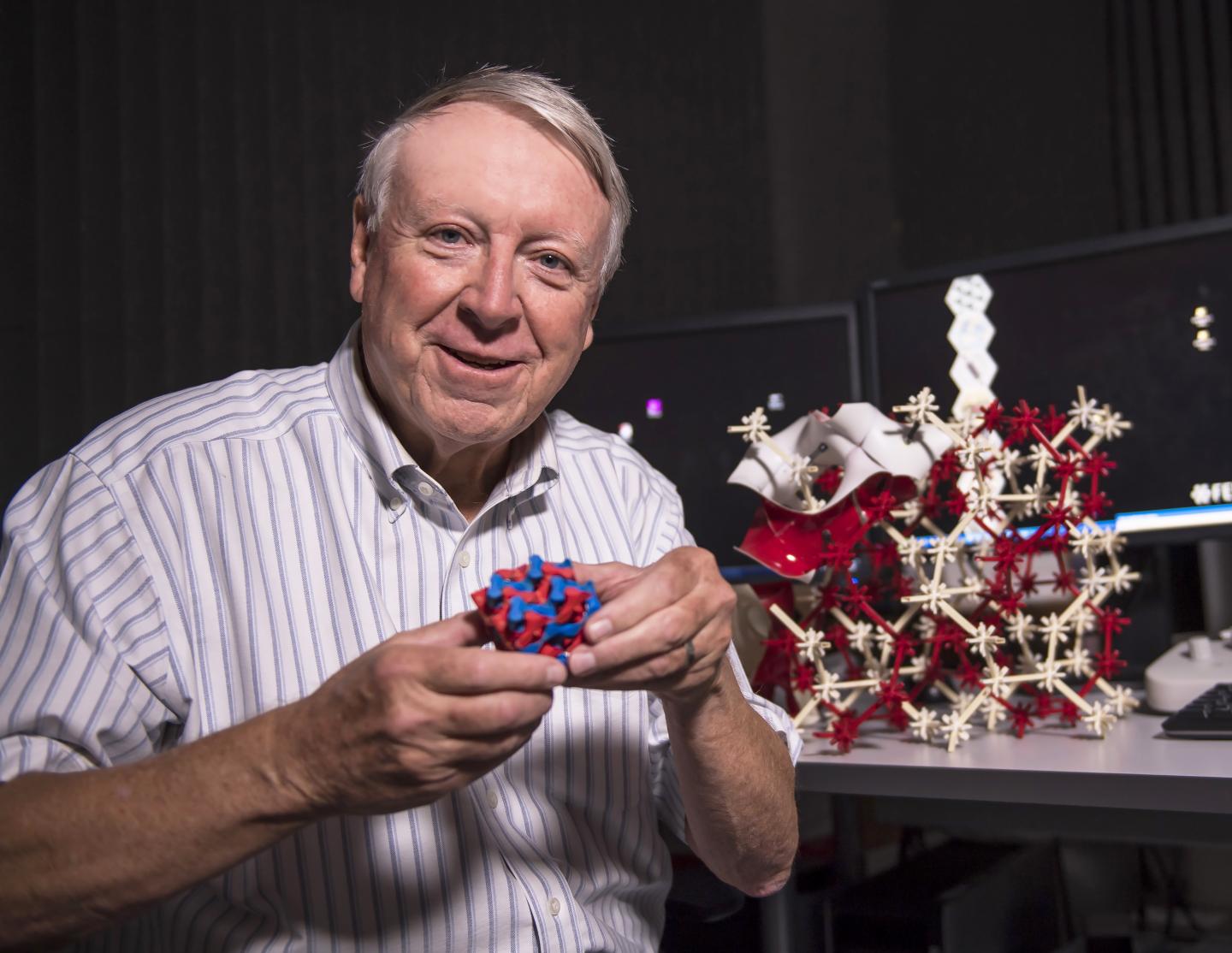

Now imagine them on the nanoscale and made of soft crystals. Materials scientist Ned Thomas of Rice University’s Brown School of Engineering has done more than imagine them — he and his lab have made and analyzed them, slice by nano slice.

Thomas and his team report in Nature their characterization of a soft-matter double gyroid. What they briefly thought would be a perfect double gyroid, its curving arrangement of nodes and rods repeating ad infinitum, was not to be. They found instead their hoped-for cubic construction was full of distortions.

A gyroid is a crystal based on triply periodic minimal surfaces, a geometry that allows its repeating form to spread out in three dimensions forever (or at least until constrained). They are sometimes found in nature; for instance, gyroids give butterfly wings their iridescence.

Scientists and engineers are interested in gyroids because of the way they interact with both light and sound waves, promising nanoscale materials with novel properties. The gyroid’s form dictates how and even whether a wave will pass through to the other side. In that way, the material can be invisible to some waves, or a reflector of other wavelengths.

Remarkably, the chemical combination of polydimethylsiloxane (PDMS) and polystyrene, initially dissolved in a solution, self-assembles into a double gyroid, with two distinct PDMS networks dancing around each other without ever touching.

A double gyroid can be even more tunable, as distinct materials making each network could affect signals differently. All this is predicated on the unit cell structure being perfect cubes.

Regrettably, the soft double gyroids that assemble into a block copolymer are not, according to Thomas, lead author and postdoctoral researcher Xueyan Feng and their colleagues.

“We call the gyroid networks red and blue, but they’re actually the same chemical compound, PDMS,” said Thomas, picking up 3D models of the nanoscale structures. “The stuff between them is styrene, and there’s more styrene than red and blue.”

If the basic repeat of the 3D pattern embedded in each gyroid were a perfect cube, that would have made the material correspond to No. 230, the last possible structure on the century-old list of space groups that categorizes all the possible 3D configurations of materials, he said.

“Mineralogists and mathematicians created this list when they became interested in, for example, why quartz crystals have the symmetry they do and figured out all the spatial arrangements of symmetry elements: translation, rotation, reflection, inversion, roto-inversion, roto-reflection, screw and glide,” Thomas said. “There are only 230 ways to put those together in self-consistent ways.

“And my group was the first to find No. 230 in block copolymers in 1994, but it turns out it’s not actually precisely cubic when it’s formed — and nobody knew that until now,” he said.

With the help of the Rice Electron Microscopy Center, the researchers adapted an electron microscope to alternatively image and then use an ion beam to gently remove a 3-nanometer slice from a double-gyroid block. They did this hundreds of times over a very large area, enabling a huge volume of the double gyroid structure to be reconstructed in high resolution.

That revealed grain boundaries throughout the structure, formed when the double gyroid nucleated in various places in solution and came together out of alignment, forcing mismatch at network intersections. They found the actual unit cell wasn’t the highest possible symmetry (cubic), but was the lowest: a triclinic cell that, while constant within a given grain, varied from grain to grain throughout the structure. That led to the overall appearance of “an average cubic,” Thomas said, while in actuality, the symmetry was significantly distorted from cubic.

“The starting polymer solution people use to make these materials is mostly solvent, and when it evaporates and the structure starts to form, the overall system is shrinking,” he said. “If it shrinks uniformly in all directions, that would be OK, but it doesn’t. Different grains and different orientations are being squashed by shrinkage forces, so it shouldn’t be a surprise to get distortions.”

That means the unit cells break symmetry as the block polymer molecules pull this way and that to reach their minimal energy binding states, Thomas said.

“The bottom line is that if you plan to use these as cubic photonic and phononic crystals with band gaps, which are all calculated based on a perfect cubic structure in a perfect, infinite, cubic lattice, you’ve got another thing coming,” he said. “You can’t make that experimentally unless you figure out some new growth techniques.”

Nevertheless, the Rice lab is working toward cubic creations, Feng said. “Turning off gravity would help, or making them in space,” he said. But without those options, the researchers are looking for a technique to evaporate the solution in all directions to relieve directional stress on the material.

“Nature doesn’t know about chirality or math or space groups,” Thomas said. “But it’s fascinating that these molecules are smart enough to do it.”

###

Co-authors of the paper are Rice alumnus Mujin Zhuo, assistant research professor Hua Guo and graduate student Kaiqi Yang; Christopher Burke, Abhiram Reddy, Ishan Prasad and Professor Gregory Grason of the University of Massachusetts, Amherst; Rong-Ming Ho, a professor of chemical engineering at National Tsing Hua University, Taiwan; and Apostolos Avgeropoulos, a professor of materials science and engineering at the University of Ioannina, Greece. Thomas is the Ernest Dell Butcher Professor of Engineering and a professor of materials science and nanoengineering, chemical and biomolecular engineering and chemistry.

The U.S. Department of Energy, Office of Basic Energy Sciences, the National Science Foundation and the Ministry of Science and Technology, Taiwan, supported the research.

Read the abstract at https:/

This news release can be found online at https:/

Follow Rice News and Media Relations via Twitter @RiceUNews.

Video:

https:/

Video produced by Brandon Martin/Rice University

Related materials:

Thomas Research Group: http://elt.

Rice Department of Materials Science and NanoEngineering: https:/

George R. Brown School of Engineering: https:/

Images for download:

https:/

Rice University materials scientist Ned Thomas holds a model of the block copolymer he and his lab created to see if the cubic structures within were perfect or not. Examination with an electron microscope showed distortions in the lattice that could affect their photonic and phononic properties. (Credit: Tommy LaVergne/Rice University)

https:/

Rice University postdoctoral researcher Xueyan Feng holds “left” and “right” chiral models of the block copolymer double gyroid created in the lab of materials scientist Ned Thomas. The double gyroid lattice turned out to be less than perfect, as demonstrated by slicing away nanoscale layers of the polymer and imaging it with an electron microscope. (Credit: Tommy LaVergne/Rice University)

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 4 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

Jeff Falk

713-348-6775

[email protected]

Mike Williams

713-348-6728

[email protected]

Media Contact

Mike Williams

[email protected]

713-348-6728

Original Source

https:/

Related Journal Article

http://dx.