TUM.Additive: a strategy towards research on additive manufacturing

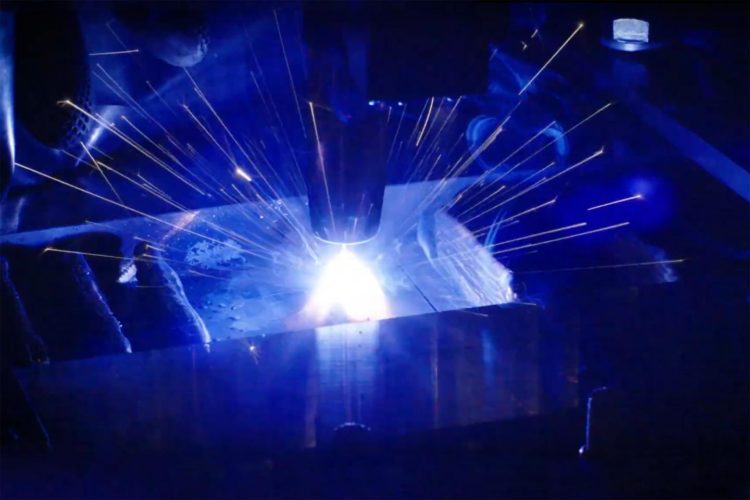

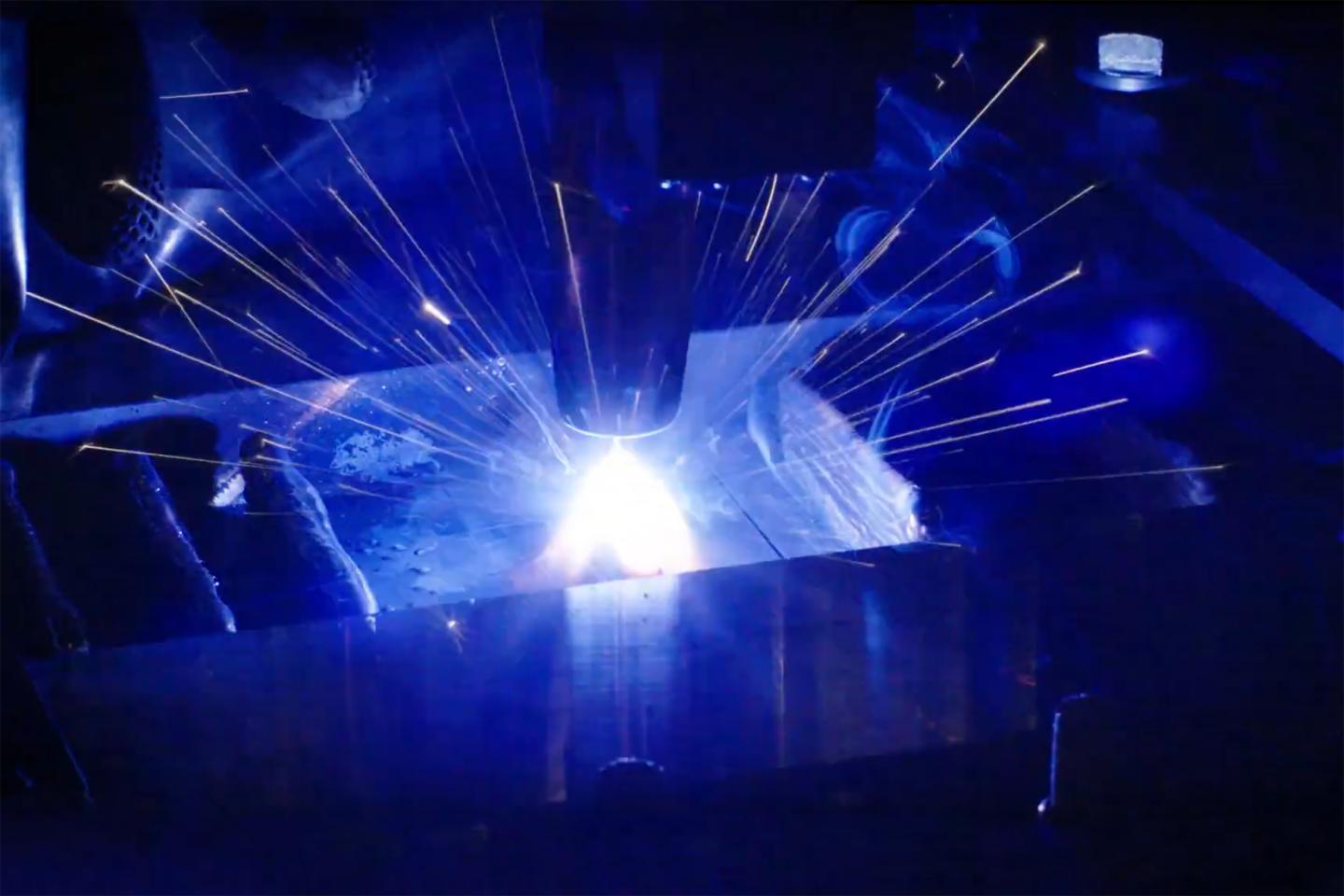

Credit: iwb / TUM

With its agenda TUM.Additive, the Technical University of Munich (TUM) is kicking off a comprehensive research focus on additive manufacturing. Together with high-tech partners in industry, TUM has founded the “Bavarian Additive Manufacturing Cluster” with the aim of establishing Bavaria as the prominent economic region for digital manufacturing technologies. TUM is now implementing the first milestone of its future strategy “TUM Agenda 2030”.

Using advanced, innovative materials and intelligent combinations, new process technologies based on digital 3D designs can be deployed to develop a wide variety of components with complex geometries in a load and function-oriented manner, building them up additively, layer for layer.

Thanks to its small energy and resource footprints, additive manufacturing can contribute significantly to achieving declared climate goals. Furthermore, additive manufacturing’s highly digitizable processes promise to bring production capacity back to Germany, and with that, highly qualified jobs.

Novel products and functionalities

Additive manufacturing facilitates the creation of new products and functionalities tailored to individual user needs. “This is in keeping with the approach of human-centered engineering – a guiding principle of TUM’s strategic development. Additive manufacturing holds vast potential for fundamentally revolutionizing the manufacturing industry,” says Thomas F. Hofmann, President of TUM, at the Munich Technology Conference on Additive Manufacturing (MTC3). The conference, which focuses on the industrial application of

additive manufacturing, is currently taking place for the third time at TUM.

Interdisciplinary expertise at TUM

“The sustainable industrial use of additive manufacturing calls for research and optimization

of the entire process chain in the core domains of materials, process technologies and digitization,” explains Hofmann.

With its TUM.Additive agenda, TUM is now bundling its extensive expertise from more

than 30 professorships in research, innovation and teaching into an interdisciplinary approach

to materials research from solids, fluids and biomaterials to their application in mechanical engineering, the automotive, aerospace and construction industries, medical technology

and the food sector.

Huge potential for Bavaria as a business location

“The integrated cooperation of powerful partners in industry and science is a prerequisite for the industrialization of additive manufacturing processes,” explains Hofmann. “This is the only way we can surmount the technological hurdles and answer the open questions of standardization.”

This is also why TUM is initiating the research alliance “Bavarian Additive Manufacturing Cluster” in collaboration with the founding partners Oerlikon, GE Additive and Linde as part of its “Industry-on-Campus” strategy. This will transform Bavaria into a leading economic region in the field of additive manufacturing.

“The starting conditions are perfect, and the potential is huge. That is why we are intensifying our cooperation with technology companies like Airbus / Ariane Group, SAP, Clariant, Siemens and TÜV Süd,” says Hofmann.

Successful start-ups in additive manufacturing

Innovative offerings will foster a new generation of specialists in the future-oriented field of additive manufacturing and sustainably support the broad implementation of AM technologies in the manufacturing industry.

Many successful corporate start-ups attest to the quality of the TUM teaching spectrum: Voxeljet develops industrial printing systems for plastics and sand, Vectoflow produces custom-designed flow probes using 3D printing, and Kumovis develops bespoke 3D printers for specific medical requirements like skull plate and spinal implants.

TUM as an additive manufacturing hub

TUM intends to expand its range of activities in the field of additive manufacturing through international collaboration. Cooperation with the German-French Academy for the Industry of the Future, the TUM flagship partner Imperial College London and the Skolkovo Institute of Science and Technology (Moscow) will deliver many new impulses.

###

Media Contact

Andreas Battenberg

[email protected]

49-892-891-0510

Original Source

https:/